Scientific Papers in SCI

2024

2024

Química de Superficies y Catálisis

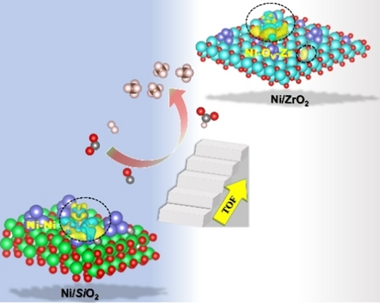

Boosting Low-Temperature CO2 Hydrogenation over Ni-based Catalysts by Tuning Strong Metal-Support Interactions

Ye, RP; Ma, LX; Hong, XL; Reina, TR; Luo, WH; Kang, LQ; Feng, G; Zhang, RB; Fan, MH, Zhang, RGAngewandte Chemie-International Edition,

Show abstract ▽

Rational design of low-cost and efficient transition-metal catalysts for low-temperature CO2 activation is significant and poses great challenges. Herein, a strategy via regulating the local electron density of active sites is developed to boost CO2 methanation that normally requires >350 °C for commercial Ni catalysts. An optimal Ni/ZrO2 catalyst affords an excellent low-temperature performance hitherto, with a CO2 conversion of 84.0 %, CH4 selectivity of 98.6 % even at 230 °C and GHSV of 12,000 mL g−1 h−1 for 106 h, reflecting one of the best CO2 methanation performance to date on Ni-based catalysts. Combined a series of in situ spectroscopic characterization studies reveal that re-constructing monoclinic-ZrO2 supported Ni species with abundant oxygen vacancies can facilitate CO2 activation, owing to the enhanced local electron density of Ni induced by the strong metal-support interactions. These findings might be of great aid for construction of robust catalysts with an enhanced performance for CO2 emission abatement and beyond.

January, 2024 | DOI: 10.1002/anie.202317669

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

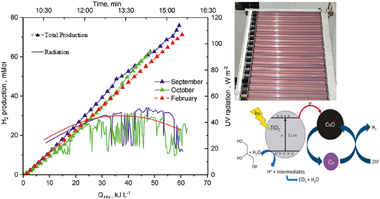

CuO-TiO2 pilot-plant system performance for solar photocatalytic hydrogen production

Villachica-Llamosas, JG; Ruiz-Aguirre, A; Colón, G; Peral, J; Malato, SInternational Journal of Hydrogen Energy, 51 (2024) 1069-1077

Show abstract ▽

The main goal of the present study was to explore photocatalytic performance of the TiO2 -CuO mixture, for solar to hydrogen conversion at pilot plant scale under two different irradiation conditions (sunny and partly cloudy), focusing on high-temperature pretreat-ment of the catalyst mixture to try to improve TiO2 doping with copper. P25-TiO2 and commercial CuO were used with different amounts of Cu (2 wt% or 7 wt% Cu) calcined at 200-400 degrees C during several hours. Catalysts were tested at pilot plant scale using solar compound parabolic collectors, with glycerol as the sacrificial agent. The photocatalyst prepared after heating at 200 degrees C for 3 h and with 7 wt% Cu, resulted in higher hydrogen production than under the other heating conditions, and results were slightly better (5 -10%) than the reference values with the untreated catalysts. Photocatalytic efficiency was slightly lower at the higher calcination temperature (400 degrees C). CO2 production and formation of formate and glycolate clearly demonstrated glycerol photoreforming. The Cu from the calcined catalyst remaining on the solid was significantly less (2.5%) than on the non -calcined catalyst (4.2%), with an important fraction of lixiviated copper and copper deposition on the reactor walls. This is a critical drawback that must be considered for large-scale applications.

January, 2024 | DOI: 10.1016/j.ijhydene.2023.07.149

Química de Superficies y Catálisis

Switchable catalysis for methanol and synthetic natural gas synthesis from CO2: A techno-economic investigation

Merkouri, LP; Mathew, J; Jacob, J; Reina, TR; Duyar, MSJournal of CO2 Utilization, 79 (2024) 102652

Show abstract ▽

The oil and gas sector produces a considerable volume of greenhouse gas emissions, mainly generated from flaring and venting natural gas. Herein, a techno-economic analysis has been performed of a switchable catalytic process to convert the CH4 and CO2 in flared/vented natural gas into syngas or methanol. Specifically, it was shown that depending on greenhouse gas composition, dry methane reforming (DRM), reverse water-gas shift (RWGS), and CO2 methanation could be chosen to valorise emissions in an overall profitable and flexible operation scenario. The switchable process produced methanol and synthetic natural gas as its products, resulting in an annual income of €687m and annual operating expenses of €452m. The pre-tax profit was calculated at €234m, and at the end of the project, the net present value was calculated as €1.9b with a profitability index of 4.7€/€. The expected payback time of this process was ca. 4 years, and with a 35% internal rate of return (IRR). Most importantly, this process consumed 42.8m tonnes of CO2 annually. The sensitivity analysis revealed that variations in operation time, green hydrogen price, and products' prices significantly impacted the profitability of the process. Overall, this techno-economic analysis demonstrated that switchable catalysis in greenhouse gas utilisation processes is profitable, and thus it could play an important role in achieving net zero emissions.

January, 2024 | DOI: 10.1016/j.jcou.2023.102652

Química de Superficies y Catálisis

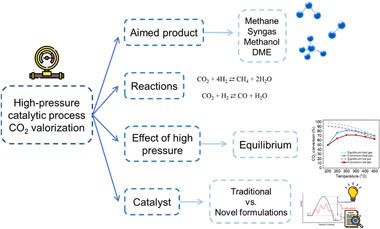

A review on high-pressure heterogeneous catalytic processes for gas-phase CO2 valorization

Villora-Picó, J.J; González-Arias, J; Pastor-Pérez, L; Odriozola, JA; Reina, TREnvironmental Research, 240 (2024) 117520

Show abstract ▽

This review discusses the importance of mitigating CO2 emissions by valorizing CO2 through high-pressure catalytic processes. It focuses on various key processes, including CO2 methanation, reverse water-gas shift, methane dry reforming, methanol, and dimethyl ether synthesis, emphasizing pros and cons of high-pressure operation. CO2 methanation, methanol synthesis, and dimethyl ether synthesis reactions are thermodynami-cally favored under high-pressure conditions. However, in the case of methane dry reforming and reverse water -gas shift, applying high pressure, results in decreased selectivity toward desired products and an increase in coke production, which can be detrimental to both the catalyst and the reaction system. Nevertheless, high-pressure utilization proves industrially advantageous for cost reduction when these processes are integrated with Fischer-Tropsch or methanol synthesis units. This review also compiles recent advances in heterogeneous catalysts design for high-pressure applications. By examining the impact of pressure on CO2 valorization and the state of the art, this work contributes to improving scientific understanding and optimizing these processes for sustainable CO2 management, as well as addressing challenges in high-pressure CO2 valorization that are crucial for industrial scaling-up. This includes the development of cost-effective and robust reactor materials and the development of low-cost catalysts that yield improved selectivity and long-term stability under realistic working environments.

January, 2024 | DOI: 10.1016/j.envres.2023.117520

Nanotecnología en Superficies y Plasma

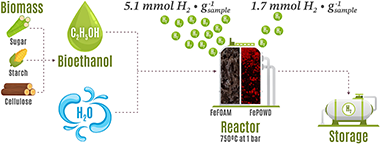

Green hydrogen production using doped Fe2O3 foams

Damizia, M; Lloreda-Jurado, PJ; De Filippis, P; de Caprariis, B; Chicardi, E; Sepúlveda, RInternational Journal of Hydrogen Energy, 51 (2024) 834-845

Show abstract ▽

Hydrogen is the ideal energy vector to reduce our fossil-fuels dependency and diminish the climate change consequence. However, current production is still methane based. It is possible to produce hydrogen using bioethanol from the alcoholic fermentation of organic waste by chemical looping processes, but unfortunately current redox systems generate hydrogen with significant traces of CO. In the case of proton exchange membrane fuel cells (PEMFC), hydrogen must be highly purified to produce electricity. Here, high porosity inter-connected Fe2O3 foams doped with 2 wt% Al2O3 were manufactured by the freeze-casting method, obtaining around 5.1 mmol H2$g?1 sample of highly pure hydrogen (<10 ppm of CO) consuming only 3.42 mmol of ethanol on each redox cycles, with no deactivation. This result shows the possibility of using an abundant and inexpensive raw material as the iron oxide to scale-up the direct pure H2 production and facilitates its use in the automotive sector.

January, 2024 | DOI: 10.1016/j.ijhydene.2023.09.008

- ‹ previous

- 5 of 410

- next ›