Artículos SCI

2012

2012

Materiales Coloidales

Chromium incorporation into TiO2 at high pressure

Escudero, A; Langenhorst, FJournal of Solid State Chemistry, 190 (2012) 61-67

Show abstract ▽

Chromium incorporation into TiO 2 up to 3 GPa at 1300 °C and 900 °C has been studied by XRD as well as TEM. A CaCl 2 type TiO 2 polymorph has been observed in the quenched samples from high pressure. Two different mechanisms of solubility occur in the recovered samples. Chromium replaces titanium on normal octahedral sites but it also occupies interstitial octahedral sites, especially in the samples recovered from higher pressures. Interstitial chromium is responsible for an orthorhombic distortion of the TiO 2 rutile structure in the quenched samples and gives rise to a (1 1 0) twinned CaCl 2-structured polymorph. This phase is very likely the result of temperature quench at high pressure. The formation of this phase is directly related to the chromium content of the TiO 2 grains. Chromium solubility in TiO 2 increases with increasing the synthesis pressure. TiO 2 is able to accommodate up to 15.3 wt% Cr 2O 3 at 3 GPa and 1300 °C, compared to 5.7 wt% at atmospheric pressure at the same temperature.

Junio, 2012 | DOI: 10.1016/j.jssc.2012.01.041

Materiales Nanoestructurados y Microestructura

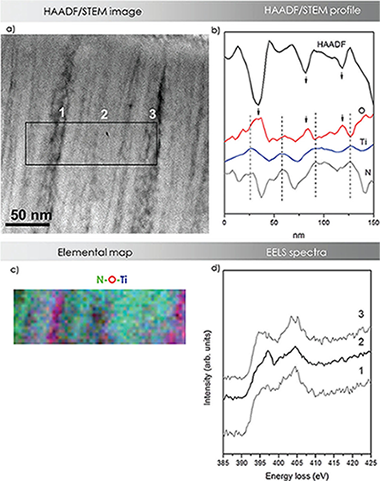

Microstructural and chemical characterization of nanostructured Tialsin coatings with nanoscale resolution

Godinho, V; Rojas, TC; Trasobares, S; Ferrer, FJ; Delplancke-Ogletree, MP; Fernandez, AMicroscopy and Microanalysis, 18 (2012) 568-581

Show abstract ▽

Nanoscale resolution electron microscopy analysis combined with ion beam assisted techniques are presented here, to give answers to full characterization of morphology, growth mode, phase formation, and compositional distribution in nanocomposite TiAlSiN coatings deposited under different energetic conditions. Samples were prepared by magnetron sputtering, and the effects of substrate temperature and bias were investigated. The nanocomposite microstructure was demonstrated by the formation of a face-centered cubic (Ti,Al)N phase, obtained by substitution of Al in the cubic titanium nitride (c-TiN) phase, and an amorphous matrix at the column boundary regions mainly composed of Si, N (and O for the samples with higher oxygen contents). Oxygen impurities, predicted as the principal responsible for the degradation of properties, were identified, particularly in nonbiased samples and confirmed to occupy preferentially nitrogen positions at the column boundaries, being mainly associated to silicon forming oxynitride phases. It has been found that the columnar growth mode is not the most adequate to improve mechanical properties. Only the combination of moderate bias and additional substrate heating was able to reduce the oxygen content and eliminate the columnar microstructure leading to the nanocomposite structure with higher hardness (>30 GPa).

Junio, 2012 | DOI: 10.1017/S1431927612000384

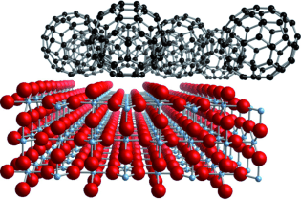

Weakly Interacting Molecular Layer of Spinning C60 Molecules on TiO2 (110) Surfaces

Sanchez-Sanchez, C; Lanzilotto, V; Gonzalez, C; Verdini, A; de Andres, PL; Floreano, L; Lopez, MF; Martin-Gago, JAChemistry-A European Journal, 18 (2012) 7382-7387

Show abstract ▽

The adsorption of C60, a typical acceptor organic molecule, on a TiO2 (110) surface has been investigated by a multitechnique combination, including van der Waals density functional calculations. It is shown that the adsorbed molecules form a weakly interacting molecular layer, which sits on the fivefold-coordinated Ti that is confined between the prominent bridging oxygen rows (see figure).

Junio, 2012 | DOI: 10.1002/chem.201200627

Nanotecnología en Superficies y Plasma

Vertical and tilted Ag-NPs@ZnO nanorods by plasma-enhanced chemical vapour deposition

Macias-Montero, M; Borras, A; Saghi, Z; Espinos, JP; Barranco, A; Cotrino, J; Gonzalez-Elipe, ARNanotechnology, 23 (2012) 255303

Show abstract ▽

Supported ZnO nanorods have been prepared at 405 K by plasma-enhanced chemical vapour deposition (PECVD) using diethylzinc as precursor, oxygen plasma and silver as the promotion layer. The nanorods are characterized by a hollow and porous microstructure where partially percolated silver nanoparticles are located. By changing different deposition parameters like the thickness of the silver layer, the type of oxidation pretreatment or the geometry of the deposition set-up, the length, the width and the tilting angle of the nanorods with respect to the substrate can be modified. Other nanostructures like nanobushes, zigzag linear structures and stacked bilayers with nanocolumns of TiO 2 can also be prepared by adjusting the deposition conditions. A phenomenological model relying on the assessment of the diverse nanostructure morphologies and the evidence provided by an in situ x-ray photoelectron spectroscopy (XPS) experiment has been proposed to describe their formation mechanism. From this analysis it is deduced that the effect of the electrical field of the plasma sheath, the high mobility of silver and silver oxide, and the diffusion of the precursor molecules are some of the critical factors that must converge by the formation of the nanorods.

Junio, 2012 | DOI: 10.1088/0957-4484/23/25/255303

Reactividad de Sólidos

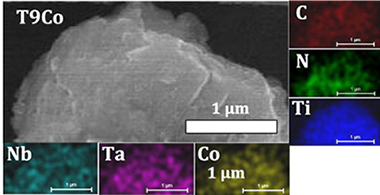

Development of multicomponent-multiphase materials based on (Ti,Ta,Nb)CxN1-x carbonitride solid solutions

Cordoba, JM; Chicardi, E; Gotor, FJChemical Engineering Journal, 192 (2012) 58-66

Show abstract ▽

A set of powdered cermets based on (Ti,Ta,Nb)C xN 1-x carbonitride solid solutions were synthesized from mixtures of elemental powders by a mechanically induced self-sustaining reaction (MSR) method and subsequently sintered using a pressureless method. Differing nominal compositions of the hard phase were used, and the nature of the metallic-binder phase (Co, Ni, or Co-Ni) was varied. For comparative purposes, the design of the material was performed using two different synthesis pathways. The composition and microstructure of the ceramic and binder phases before and after sintering were analyzed and related to the microhardness of the material, which was found to increase with increasing contiguity of the hard phase and with decreasing particle size.The samples synthesized in one step (SERIES 2) showed higher microhardness and a more homogeneous microstructure with smaller particle size of the hard phase due to the presence of Ti, Ta, and Nb in the molten binder that hindered ceramic growth during liquid phase sintering.

Junio, 2012 | DOI: 10.1016/j.cej.2012.03.046

- ‹ anterior

- 330 of 422

- siguiente ›