Engineered Ceramics for Extreme Environments

Research Group:

- Designed Materials for the Energy and Environment

Catedráticos

Castro Arroyo, Miguel AngelCatedráticoUniversidad de Sevilla ✉ macastro@us.es ☎ 954 48 95 46 ✆ 446146 ORCID 0000-0001-6533-1343 Materiales de Diseño para la Energía y Medioambiente |

Jiménez Melendo, ManuelCatedráticoUniversidad de Sevilla ✉ melendo@us.es ☎ 954 55 97 36 ORCID 0000-0002-8423-5928 Materiales de Diseño para la Energía y Medioambiente |

Malet Maenner, María del PilarCatedráticaUniversidad de Sevilla ✉ malet@us.es Materiales de Diseño para la Energía y Medioambiente |

Martínez Fernández, JuliánCatedráticoUniversidad de Sevilla ✉ martinez@us.es ☎ 954 55 28 94 ORCID 0000-0002-1199-6638 Materiales de Diseño para la Energía y Medioambiente |

Ramírez de Arellano-López, AntonioCatedráticoUniversidad de Sevilla ✉ aral@us.es ☎ 954 55 97 32 Materiales de Diseño para la Energía y Medioambiente |

Ramírez Rico, JoaquínCatedráticoUniversidad de Sevilla ✉ jrr@us.es ☎ 954 55 97 58 ORCID 0000-0002-1184-0756 Materiales de Diseño para la Energía y Medioambiente |

Investigadores Científicos

Alba Carranza, María DoloresInvestigadora CientíficaCSIC ✉ alba@icmse.csic.es ☎ 954 48 95 46 ✆ 446146 ORCID 0000-0003-0025-3078 Materiales de Diseño para la Energía y Medioambiente |

Científicos Titulares

Benítez Jiménez, José JesúsCientífico TitularCSIC ✉ benitez@icmse.csic.es ☎ 954 48 95 51 ✆ 446147 ORCID 0000-0002-3222-0564 Materiales de Diseño para la Energía y Medioambiente |

Profesores Titulares

Bravo León, AlfonsoProfesor TitularUniversidad de Sevilla ✉ albravo@us.es ☎ 954 55 09 37 ORCID 0000-0001-7399-5190 Materiales de Diseño para la Energía y Medioambiente |

Pavón González, EsperanzaProfesora TitularUniversidad de Sevilla ✉ epavon@icmse.csic.es ORCID 0000-0002-4476-4403 Materiales de Diseño para la Energía y Medioambiente |

Doctores Contratados

Mesquita Coelho, Joao CarlosDoctor ContratadoUniversidad de Sevilla ✉ jmesquita@us.es ORCID 0000-0003-4217-3842 Materiales de Diseño para la Energía y Medioambiente |

Personal Investigador en Formación

Chaparro Barajas, Javier RamiroInvesigador en FormaciónUniversidad de Sevilla ORCID 0000-0001-6254-2962 Materiales de Diseño para la Energía y Medioambiente |

Thermochemical Energy storage materials enhanced by microstructural control

Investigador Principal: Luis Allan Pérez Maqueda / Pedro Enrique Sánchez Jiménez

Periodo: 01-09-2022 / 30-11-2024

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: TED2021-131839B-C22

Componentes: Joaquín Ramírez Rico, José Manuel Valverde Millán, Antonio Perejón Pazo

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente, Reactividad de Sólidos

The main objective of the MOTHERESE project is the development of a new concept of thermochemical energy storage based on the "Calcium-Looping" process. The novelty of the concept lies in scaling down the storage component and making it modular, easily integrated in power generation plants of different nature, storable and mobile. Subproject 2 focuses on aspects related to the development of materials suitable for these new operating conditions, as well as their optimization at this new scale.

The aim is to address the development of these materials with emphasis on preparation techniques that favor morphologies and microstructures that optimize (i) the kinetics of solid-gas reactions, in order to reduce residence times, (ii) multicyclic stability, minimizing deactivation by sintering and pore blocking, and (iii) active surface area, maximizing the amount of reagent available for conversion in each cycle. This will be achieved by using freeze casting and freeze granulation techniques, particularly suitable for the fabrication of ceramic structures with open porosity and directed morphology. The use of additives to improve the performance of the material is also considered. Finally, the integration of the active material and additives of high thermal conductivity in stable three-dimensional structures is contemplated, which not only improve the cyclability and efficiency of the active material but also ensure fast and efficient heat transfer, necessary for the modular system. Finally, new operating conditions compatible with the new scale will be explored, from low pressures to high pressures of up to 5 bar, always maintaining a closed cycle that avoids the need for gas separation.

MOTHERESE is committed to the circular economy, and therefore aims to use by-products and waste from other industries as a source of additives and even of the active material itself, CaO, favoring the use of waste. These include steel mill slag, biogenic carbonates (mollusks), cellulosic materials and rice husks (source of SiO2).

To address these objectives, the subproject has a multidisciplinary team of chemists, engineers, physicists and materials specialists with experience in the management and participation in national and international research projects, including relevant projects focused on thermochemical energy storage. In addition, the team has an international network of academic and industrial collaborators that would allow in the exploitation of the results obtained and the proposal of new international projects in this same line.

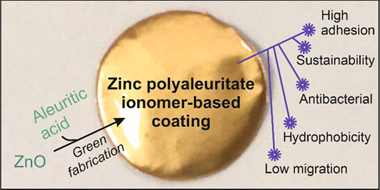

Upcycling of potato peel by-products into sustainable, multifunctional lacquers for food metal packaging (POP-UP)

Investigador Principal: José Jesús Benítez Jiménez / José Alejandro Heredia Guerrero (IHSM)

Periodo: 01-12-2022 / 30-11-2024

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: TED2021-129656B-I00

Componentes: Eva María Domínguez Carmona (IHSM), Mª de la Montaña Durán Barrantes (IHSM), Antonio Heredia Bayona (IHSM), Jorge Rencoret Pazo (IRNAS), José Carlos del Río Andrate (IRNAS), Diego Francisco Romero Hinojosa (IHSM)

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

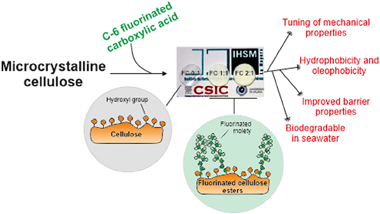

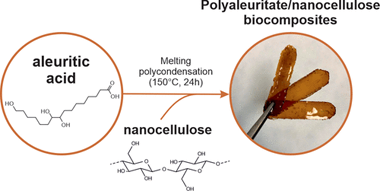

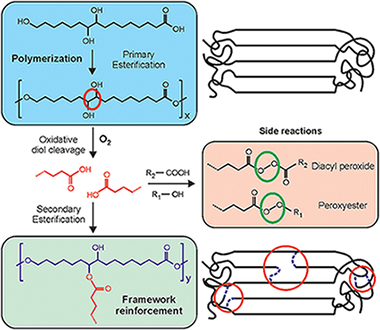

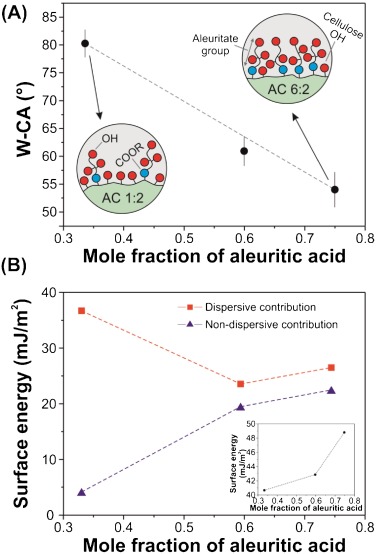

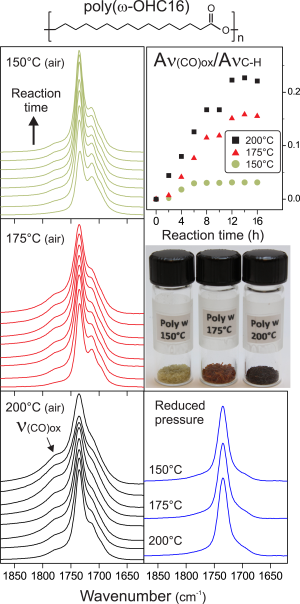

POP-UP project aims to provide, in terms of circular bioeconomy, sustainable, safe, and economically viable solutions to the massive use of petroleum-based BPA resins in food packaging through the fabrication of multifunctional, high-performance coatings for metal substrates from inexpensive, underutilized agro-food by-products. In particular, peels resulting from the industrial food processing of potatoes will be used as a bio-renewable resource of suberin monomers to fabricate biodegradable, bio-based lacquers by green and large-scalable technologies (i.e. spray from aqueous solutions and free-solvent, non-catalyzed melting polycondensation) for sustainable and innocuous food packaging. This suberin-based coating will offer same benefits and properties with respect to BPA resins, but it will be designed to be fully non-toxic and with antimicrobial properties. Hence, main objectives are related to improve food security, to contribute to an ecological transition from a linear fossil-based economy to a circular bioeconomy, and to increase agricultural productivity by upcycling plant residues.

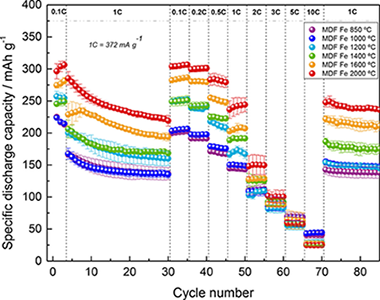

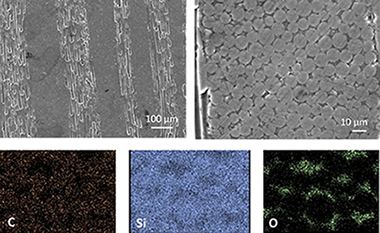

Biomass for DEsalination via CApacitive Deionization and Energy Storage, “BioDECADES”

Investigador Principal: Joaquín Ramírez Rico

Periodo: 01-01-2022 / 31-12-2022

Organismo Financiador: Junta de Andalucía

Código: US-1380856

Componentes: Alfonso Bravo León, Manuel Jiménez Melendo, Julián Martínez Fernández

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

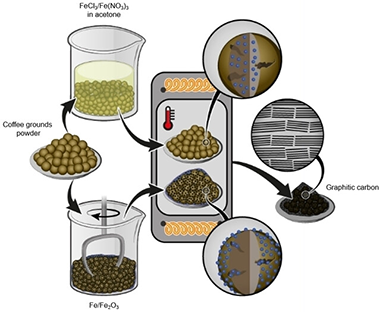

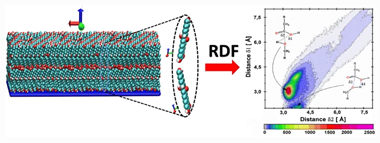

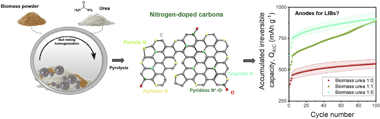

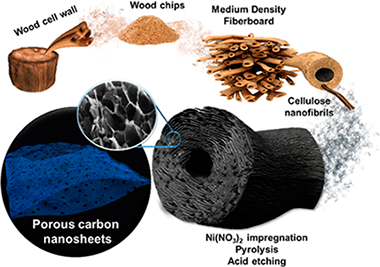

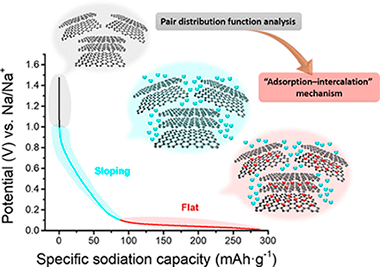

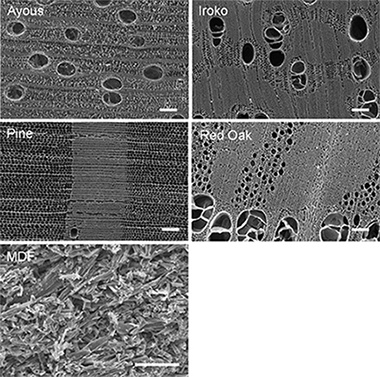

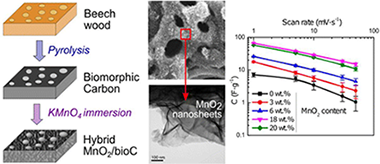

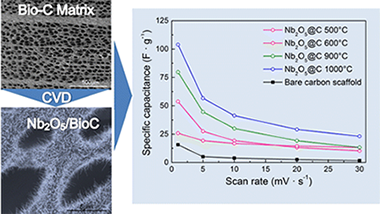

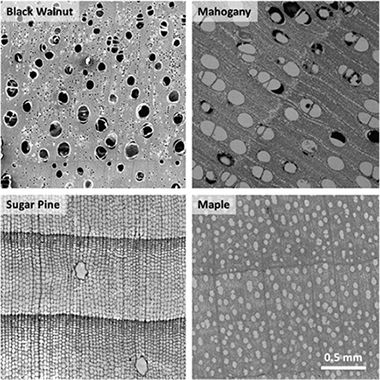

Water resources, global warming and the decline of fossil fuels are three of the main challenges that we as a society will have to address in the next decade. Solutions to these challenges rely on the development of new technologies that allow the efficient use and reuse of water resources, as well as on new, high power and high energy density storage systems to be coupled with renewable sources. These two seemingly unrelated topics currently rely on one technology: carbon adsorbents and electrodes. Both desalination and purification systems as well as supercapacitors and batteries use materials that are based on carbon, their structure modified through physical and/or chemical processes. Biomass is a cheap, widely available precursor for carbon materials, which can be obtained by pyrolysis. Both the choice of biomass as well as the actual process will determine the final properties of the carbon electrode, which can be tailored for targeted applications.

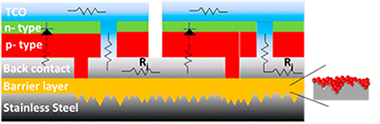

Capacitive deionization (CDI) is an emerging desalination technology with tunable salt removal levels, that uses a small voltage applied across two carbon electrodes to remove ions from solution by means of Electrosorption. The small amount of energy required means that such a system can be powered by a solar panel, making this technology useful in portable and deployable systems. Supercapacitors and batteries also rely on adsorption and/or intercalation mechanisms to store electric charge, in a process that is essentially the same but with a different final target as CDI. Both technologies rely on the use of carbon electrodes, with properties and structure tailored to each of the applications.

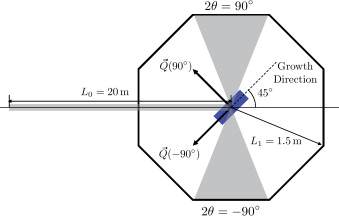

This proposal’s main objective is to use biomass residue as a precursor to develop tailored carbon electrodes for electrochemical applications related to energy and environmental technologies, with a focus on two main applications: energy storage in supercapacitor systems and batteries, and desalination via CDI. The main proposed synthesis approach for this electrodes will be the pyrolysis of biomass precursors, with a focus on biomass waste products such as grain husks, peels, pits and stones and other organic waste. In the case of monolithic electrodes, wood and wood-derived fiberboards will be the main focus. Chemical methods will be developed to functionalize the resulting carbons, to improve their capacitance or ion selectivity.

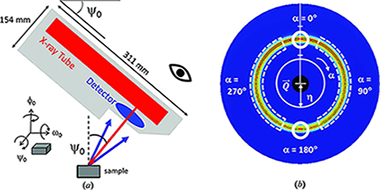

We will build a CDI testing rig to determine desalination behavior, and to correlate this with microscopic information obtained from advanced techniques such as electron microscopy, total scattering diffraction experiments, nitrogen adsorption isotherm, and others. We will test the electrochemical energy storage behavior and correlate it with structural properties and processing conditions. Our goal will be to optimize carbon electrodes derived from biomass for targeted applications, and to develop a menu of biomass derived carbon materials.

Biomorphic materials for energy storage (BioMatStor)

Investigador Principal: Joaquín Ramírez Rico

Periodo: 05-10-2021 / 31-03-2023

Organismo Financiador: Junta de Andalucía

Código: P20_011860 - PAIDI 2020

Componentes: María Dolores Alba Carranza, Alfonso Bravo León, Manuel Jiménez Melendo, Esperanza Pavón González

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

Biomass derived carbon materials will play a key role in several energy conversion and storage technologies in the future, with application in supercapacitors and batteries, power-to-X systems (fuel cells and electrolyzers), CO2 and H2 storage. Large amounts of biomass waste are generated in local agrofood industries. Among these wastes, the overall estimated production of olive stones in Spain is approximately 1,050,000–1,400,000 tons per year (campaign of 2017). The main use of this byproduct has been as solid biofuel for domestic applications, but given its abundance and low cost, this project presents an opportunity to convert what is considered waste into an added value product.

This proposal’s main objective is to develop tailored carbon materials for applications related to energy and environmental technologies, with a focus on three main applications: i) electrochemical energy storage; ii) catalyst supports in fuel cells and electrolyzers; iii) and gas storage and capture, with a focus on both hydrogen and carbon dioxide storage and separation processes. The main proposed synthesis approach for these materials will be the pyrolysis of biomass precursors, with a focus on biomass waste products such as grain husks, peels, pits and stones and other organic waste. A first objective will be to perform a survey of readily available biomass waste materials from regional agrofood industries. A second objective will be the investigation and optimization of pyrolysis and activation routes to obtain carbon materials with tailored properties for each of the applications targeted in this project. Lastly, a third objective is to assess the applicability and the potential for the application of these materials at commercial scale.

Extensive physical and chemical characterization of the obtained carbon materials will be performed and testing of the resulting materials for the targeted applications will allow us to tailor the processing parameters. A scale-up analysis, with definition of materials integration and systems configurations will be performed by means of simulations, as well as technological and industrial applicability evaluation and assessment of the feasibility of the proposed approach in the large scale. BioMatStor develops R&D at different levels of application: fundamental for materials science characterization and manufacturing, and applied science for energy storage systems modeling and characterization. This Project combines Materials Science and Energy Engineering with the goal of obtaining highly performing materials for a wide range of applications in energy production and storage. Such a proposal requires a multidisciplinary approach, as evidenced in the research team and collaborators. We propose a multidisciplinary approach which has its foundation in scientific excellence, responds to societal challenges and may result in a significant technology transfer to the industry. This project also addresses the socio-strategic goals of Horizon 2020 as it aims to contribute to the improvement of our environment through advanced science and multidisciplinary research. It is fully aligned with the objectives and policies of European Union, the Energy Union Energy, H2020, SET Plan and Andalucía region RIS3 objectives.

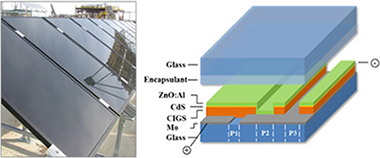

Proton conducting ceramics for high efficiency reversible electrolyzers and power to X applications

Investigador Principal: Joaquín Ramírez Rico / Ricardo Chacartegui Ramírez

Periodo: 01-06-2020 / 31-05-2023

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: PID2019-107019RB-I00 "Retos de la Sociedad"

Componentes: Alfonso Bravo León, Manuel Jiménez Melendo, Julián Martínez Fernández, Miguel Torres García

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

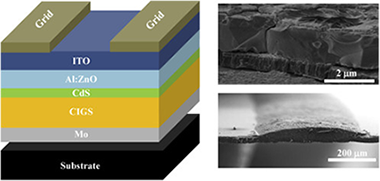

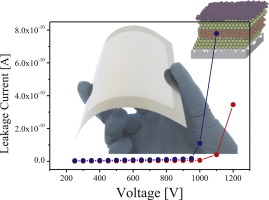

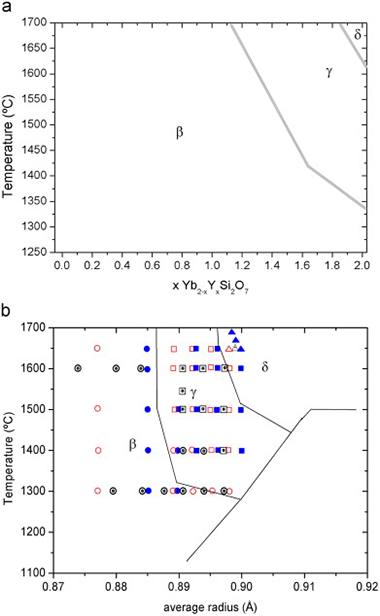

PROCEX is aimed at the Social Challenge 3 “Secure, Clean and Efficient Energy”. It aims to open a new pathway for high-efficiency reversible electrolyzers for intermediate temperatures (around 500ºC). Its successful development would open a very promising pathway for energy storage systems in PV and Wind facilities with outstanding characteristics, round-trip efficiencies (75% or higher), and Energy Returned On Investment (>10). These values are much higher than those that can be reached with state of art of thermal energy storage systems. Besides, such a high efficiency concept electrolyzer would have a huge field of application for H2 production and application in the chemical industry. To develop such systems, several materials challenges need to be solved. In particular, novel electrolytes formulations with reduced electronic conductivities are needed.

The project is aimed at the identification and demonstration of new proton conducting ceramic materials that will have reduced electronic leakages in electrolysis operation, based on doping and co-doping strategies in barium cerate and zirconate systems. Emphasis will be placed not only in improving the efficiency but also the durability of such materials. The project will demonstrate the manufacturing of material and electrolyte at laboratory level and it will study the main reaction mechanisms developing models for their understanding and to support the pathways for concept application and scaling up. The project departs from results presented in literature this year that are fully aligned with capacities and previous experience of the participating R&D teams. The project will go further from these results extending the material compositions to develop, tailoring them to specific applications, widening the understanding of the reactions mechanisms and the effects of materials as well to the operation in the materials (i.e. degradation and aging effects). From this approach, within the project new models are expected to be developed and validated and the integration of the concept in different applications will be assessed. The ambition of the project requires a multidisciplinary approach that is developed by two R&D teams, from Material Science and Energy Engineering areas with all the capacities required for the successful development of the project: manufacturing, testing modelling and develop the new concepts and with expertise in materials processing and characterization, electrochemical models, and energy storage systems.

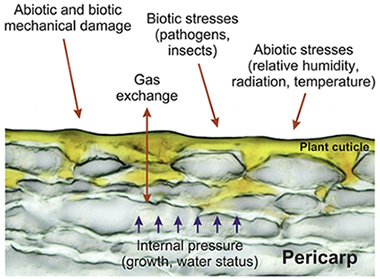

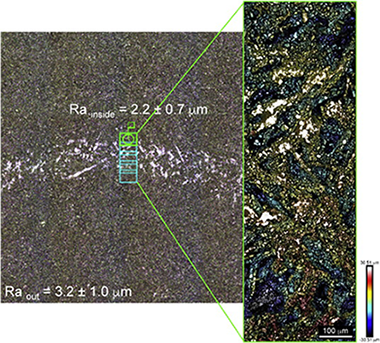

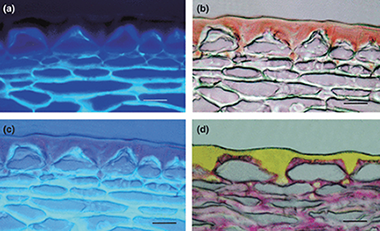

Unraveling the genetic and biophysical basis of tomato fruit cuticle formation

Investigador Principal: Eva María Domínguez Carmona (IHSM) / Rafael Muñoz Fernández (IHSM)

Periodo: 01-01-2019 / 30-06-2022

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: RTI2018-094277-B-C22 "Retos de la Sociedad"

Componentes: José Jesús Benítez Jiménez, Manuel León Camacho (IG)

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

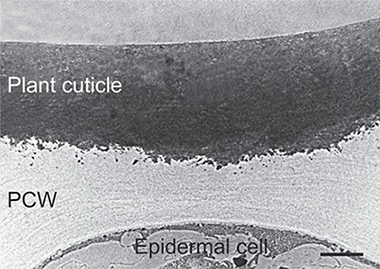

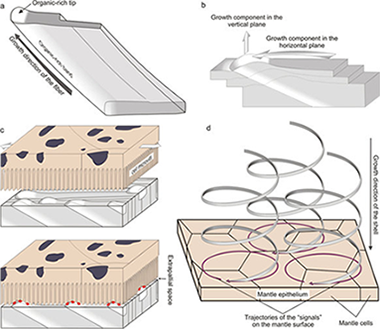

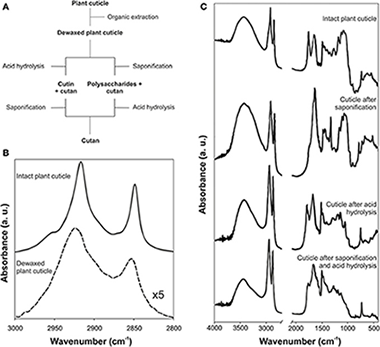

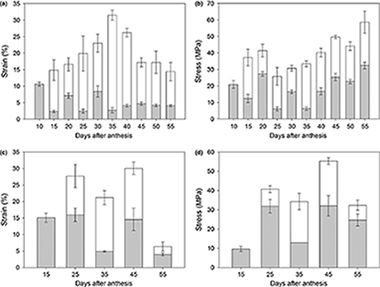

Waxes and phenolics are minor compounds of the tomato fruit cuticle that nevertheless play a significant role in determining several aspects related to fruit quality. Phenolics have been demonstrated to modulate fruit color appearance and cuticles stiffness, thus determining fruit sensitivity to cracking during ripening. They are not, however, the only contributors to the mechanical properties of the cuticle. In previous projects we located and validated five QTLs related to the amount of cuticle phenolics, identification of the genes responsible for these genomic regions will improve our understanding of this trait and how to modulate it in order to generate commercial lines with desirable combinations of fruit color and mechanical resistance. In this sense, a QTL analysis of the mechanical and thermal properties of the cuticle will be the first known approach to the genetic basis of a biophysical property. Cuticular waxes, on the other hand, are the major barrier to water permeability and, in this sense, regulate the hydric status of fruits during harvesting, post-harvest and storage. A preliminary analysis of wax content in the wild species related to the cultivated tomato, revealed two red-fruited species of potential interest for developing new varieties with tolerance to dehydrating environments. The analysis of water permeability and wax quality of the cuticle in this two species will be the first step towards this ultimate goal.

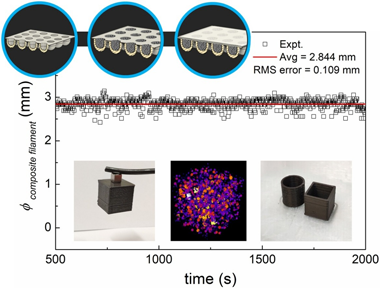

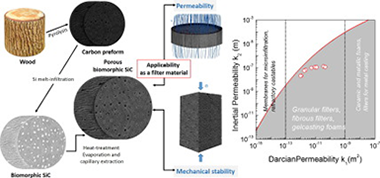

Bioceramic Materials for New Biomass Domestic Bolier Concept based on Porous Combustion for a Wide Biomass/Residues Feedstock

Investigador Principal: Joaquín Ramírez Rico

Periodo: 30-12-2016 / 31-12-2020

Organismo Financiador: Ministerio de Economía y Competitividad

Código: MAT2016-76526-R "Retos de la Sociedad"

Componentes: Julián Martínez Fernández, Manuel Jiménez Melendo

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

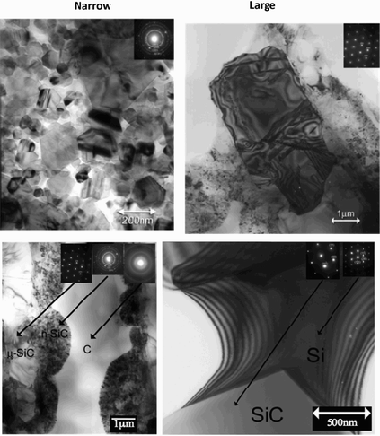

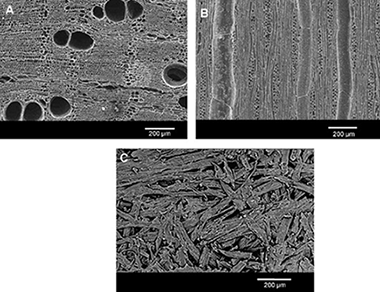

EU generates more than five tons of waste per person every year and about 60 % is organic waste. Current biomass domestic boiler technology does not allow the use of these residues with high efficiency, ultra-low emissions and high reliability operation. The main objective of this proposal is the development of a new concept of biomass domestic boiler technology able to combine these characteristics for operation with multiple biomass/residues blends. It is based on the integration of novel bioceramic porous materials matrices in combustion chamber and gases pathflow with functions as microporous combustors, particles filters and heat accumulators. These functions are simultaneous depending on the region of the boiler. Matrices of bioceramic materials are developed from wood precursors to obtain SiC elements through a process patented by the University of Seville. It uses local raw material, and produces parts with tailor made microstructure/properties, adequate for high temperature and reactive operation. Products with complex geometries can be obtained at relatively low cost compared with other materials of similar chemical and mechanical properties. The integration of components based on these materials allows new designs of biomass boilers with high control of combustion, temperature and particle emission. It avoids ash sintering and melting, acting on the formation and evolution mechanisms of ash and dioxins and activating the complete oxidation of CO and soots. The new concept allows the operation to a wider biomass/residues feedstock with low emissions and low maintenance even with fuels with high ash content, produced from many residues, solving main challenges for their extended use and increasing the European fuel resources for domestic heating. Domestic heating in Europe consumes 30% of the total energy. The proposal includes prototypes development, fuel supply characteristics and preparation (geometry, compactness, composition, etc.) and combustion products management. Biomass/residues blends from agriculture, forestry, olive oil industry among others will be tested both in laboratory .

Genetic basis of the composition and biophysical properties of tomato fruit cuticle: exploiting natural variability

Investigador Principal: Fafael Fernández Muñoz (IHSM)

Periodo: 01-01-2016 / 31-12-2018

Organismo Financiador: Ministerio de Economía y Competitividad

Código: AGL2015-65246-R

Componentes: José Jesús Benítez, Fernando Gallardo Alba (UMA), Antonio Heredia Bayona (IHSM)

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

Production of fruits with high quality and added value is currently an important challenge in agriculture. The cuticle that covers the outer epidermal cell walls plays a significant role in tomato fruit quality mainly in its external appearance (color, glossiness, texture, uniformity), in the occurrence of disorders of great economical importance such as fruit cracking, and also in the maintanance of fruit water status during postharvest. In previous projects (AGL2006-12494, AGL2009-12134 and AGL2012-32613) of which this can be considered a continuation, the important role of cuticle on fruit cracking and how changes in cuticle biomechanical properties affect cracking were highlighted. Moreover, it was shown that cuticle flavonoids, which are involved in the color of ripen fruits, play an important role in the regulation of cuticle synthesis and water permeability. Both a recombinant inbred (RIL) and an introgression line (IL) S. lycopersicum x S. pimpinellifolium populations will be used for validation and identification of QTLs and candidate genes involved in the deposition of different cuticle components (waxes, cutin, flavonoids, polysaccharides) and also for identification of QTL/genomic regions associated to unstudied cuticle traits such as thickness and density. This multidisciplinary approach, that includes cuticle biophysical analyses, will allow designing tomato cultivars with adequate biomechanical and hydrodinamical properties to reduce cracking, maintaining fruit water status during postharvest and avoiding skin traits undesirable for consumers. A collection of wild tomato species accessions will be studied and will provide insights in cuticle evolution within the Lycopersicon taxon. This evolutionary study could reveal different combinations of components and structures that will be useful to increase the current cuticle variability for future breeding programs.

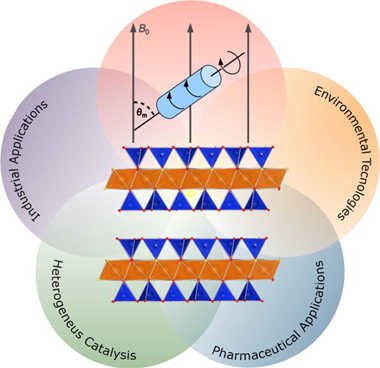

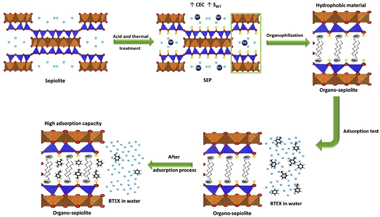

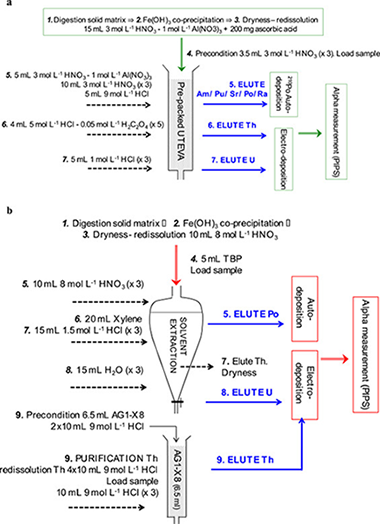

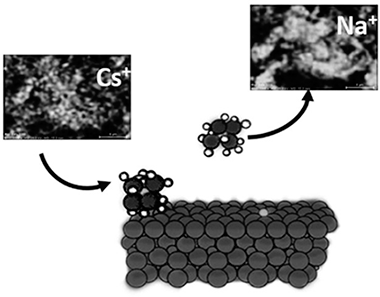

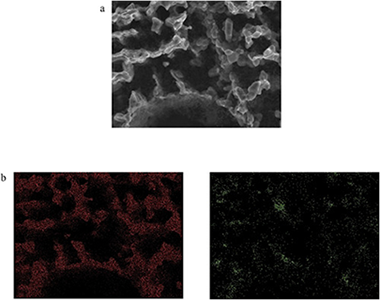

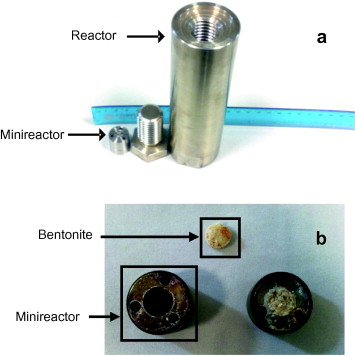

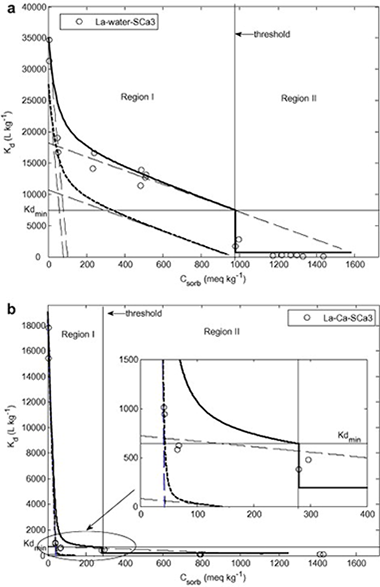

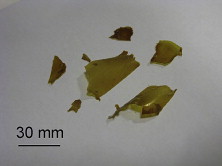

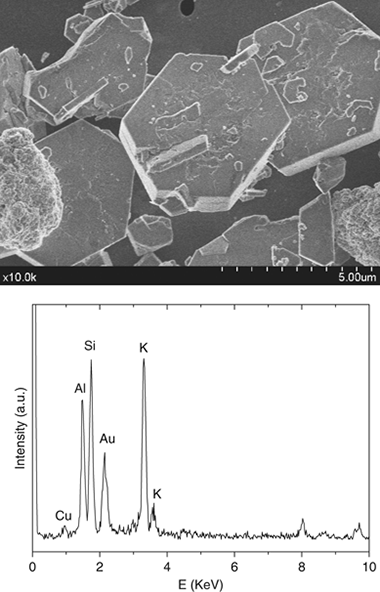

Susteinable industrial waste treatment: designed adsorbent materials and bionanocomposites for inmobilizing heavy metals and fision products

Investigador Principal: Maria Dolores Alba Carranza

Periodo: 01-01-2016 / 30-06-2019

Organismo Financiador: Ministerio de Economía y Competitividad

Código: MAT2015-63929-R

Componentes: Miguel Angel Castro Arroyo, Ana Carmen Perdigón Aller, María del Mar Orta Cuevas

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

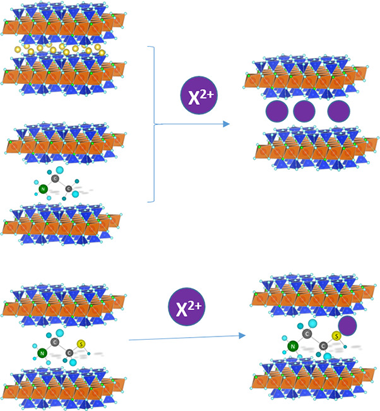

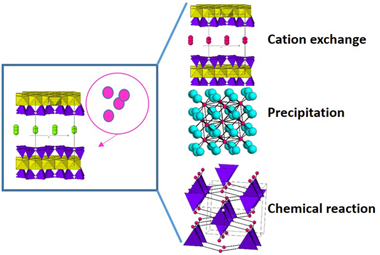

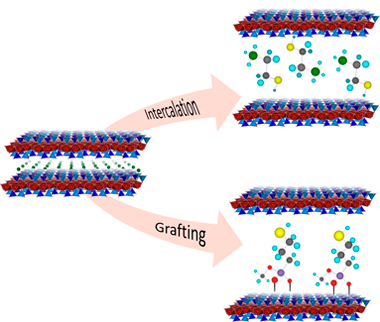

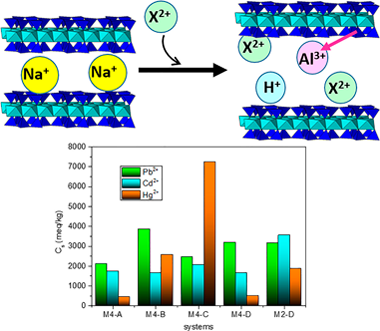

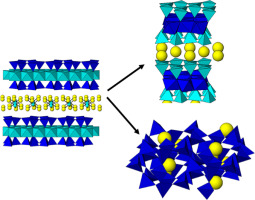

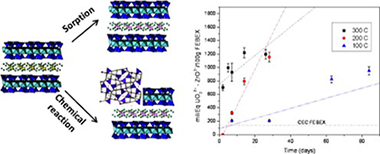

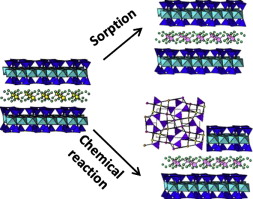

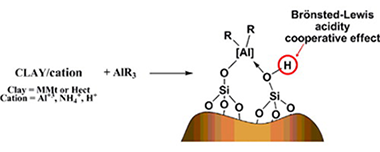

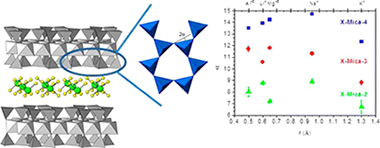

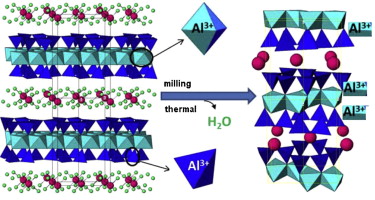

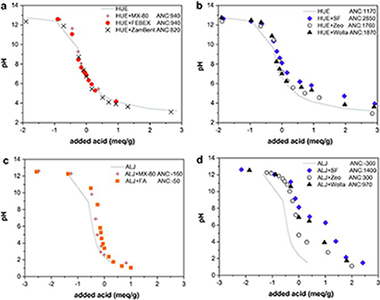

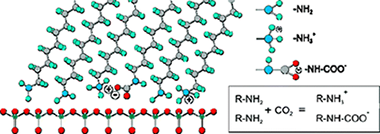

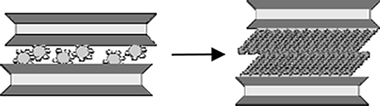

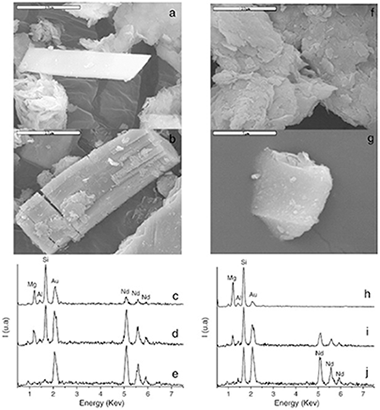

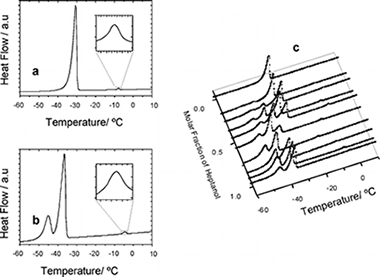

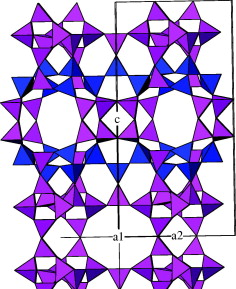

The focus of the project addresses the requirement of advanced environmental technology methodologies for removing pollutants. Recently, the interest and efforts to develop new technologies for more efficient treatments for the immobilization and the revaluation of hazardous waste are increasing in R & D plans. The overall object of the project is based on the design of a strategy of functionalization of highly charged swelling phyllosilicates and their later transformation on bionanocomposite for the effective retention and immobilization of hazardous waste, both cationic and anionic. This object represents a qualitative change in the work that is being nowdays developed in the field of model adsorbents systems with environmental applications that will improve the quality life of the population and the environmental conservation, because the designed functionalization of the synthetic silicates will allow the adsorption of a wide range of adsorbents in different oxidation states, cationic or anionic. The objectives are conformed to the Focus Area WASTE of the H2020 program and it is developed on the 2nd and 5th challenge of the H2020 program and on the 5th and 3rd challenge of the national research program.

The project has attracted interest from various observers companies, EPOs, (ENRESA and the Water and Local Energy Agency and Sustainability of the City of Seville), the public-private collaboration being promoted. Therefore, the research combines the basic principles of the National Strategy of Science and Technology: Putting the R&D&I at the service of citizens, social welfare and sustainable development, making the R&D&I a factor of improving business competitiveness (transfer of results to the private sector, see interest of EPOs) and recognize and promote R&D&I as an essential element for the generation of new excellence knowledge.

The viability of the proposal is ensured, first, because the research team, RT, has accomplished the synthesis of hydratable high charged phyllosilicates, with a novel and original method that allows setting the material desired charge, and, later, has successfully achieved their organofunctionalization (patent ES 2 362 597 B1). Second, the RT has developed the required methodology for the development of this project in closed scientific collaboration with other well recognized international groups (i.e. CNRS-University of Lille, University of Cambridge...). The RT enhances the clustering of their capabilities and scientific-technical skills which are essential to address this proposal with a remarkable transverse character.

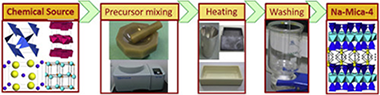

Adsorption mechanisms study of harmful anionic pollutants by tailor-made aluminosilicates

Investigador Principal: Esperanza Pavón González

Periodo: 01-02-2015 / 28-02-2017

Organismo Financiador: Junta de Andalucía

Código: TAHUB-082. Programa Talent HUB

Componentes:

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

The scientific, technological and industrial development carried out in the second half of last century has caused an increasing pollution in the natural environment. Consequently, a widespread recognition of the need to develop technologies and strategies for pollution control has arisen in the recent times. The main objective of this Project is to design swelling layered silicates of high charge and their surface modification for an effective activity with respect to the retention and immobilization of toxic and dangerous anionic wastes.

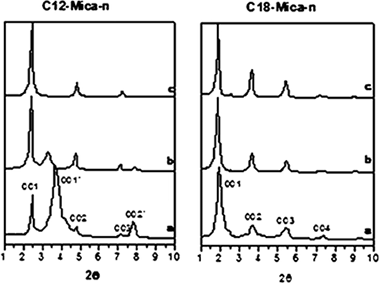

The proposed methodology consists on the synthesis of high charge swelling mica with isomorphic substitution of Si4+ by Al3+ with a charge density in the range of brittle mica but with a cation exchange and swelling capacities unusual in these silicates. In order to enhance the anionic adsorption capacity, the mica will be functionalized in the surface with magnetite and with the inclusion of alkylammonium cations in their interlayer space.

An immobilization protocol of harmful anionic products like AsO42-, SO42- will be established, using the best adsorbent in function of both the structure and the funcionalization of the highly charged swelling mica. Afterwards, the applicability of these adsorption reactions will be tested in actual contaminated soils from Chili and Spain.

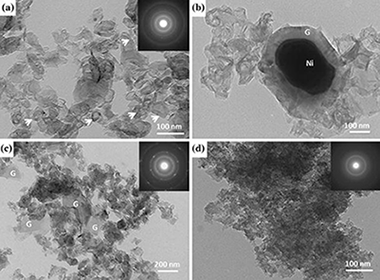

Development of processes for the catalytic combustion of hydrogen and study of the integration in devices for portable applications

Investigador Principal: Asunción Fernández Camacho

Periodo: 16-05-2014 / 15-05-2016

Organismo Financiador: Junta de Andalucía

Código: P12-TEp-862

Componentes: Julián Martínez, Gisela Arzac, Dirk Hufschmidt, Joaquín Ramírez, M.Carmen Vera, Vanda Godinho, Lionel Cervera, T.Cristina Rojas, Olga Montes, Mariana Paladini, Jaime Caballero-Hernández

Grupo de Investigación: Materiales Nanoestructurados y Microestructura, Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

Hydrogen is an attractive candidate as a vector for storage and transport of energy in the context of an increased use of renewable and clean energies. The production and use of energy based on hydrogen technology is particularly important for small-scale portable (and potentially scalable for stationary) applications. In this project the process of catalytic (controlled) combustion of hydrogen will be investigated in the various aspects that could lead to a final integrated configuration with a H2 generation system for portable applications. For that the project will take advantage of the synergy of integrating two researcher groups from the PAI: i) The TEP217 group, specialists in storage and generation of hydrogen based on metal hydrides, complex hydrides and hydride composites reactive systems; and in the use of catalysts and additives to control and improve the kinetics of these processes. ii) The FQM342, specialist group for the fabrication of porous ceramics of high interest as catalyst supports for harsh combustion environments. Further collaboration is completed with the participation of the company Abengoa Hidrógeno SA that will be involved as sub-contractor as specialist in systems for the production and storage of hydrogen.

In particular we will work on this project in the following lines:

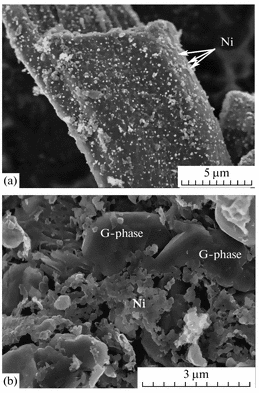

1.- Development of catalysts and supports for catalytic combustion. Typically porous biomorphic silicon carbide ceramics and classic noble metal catalysts, as well as new low cost catalysts to be developed in the project.

2.- Development of reactors needed for the study of the catalytic combustion. Typically hydrogen flows from a few ml/min to the scale of a H2 generator already available in the range 0.5 to 1.5 L/min.

3.- Coupling the catalytic combustion system with a portable hydrogen generation systems that we have developed in previous projects.

4.- Application of the sputtering technology in an exploratory manner in this project to deposit the catalyst materials for the H2 catalytic combustion on porous substrates.

5.- Microstructural and chemical characterization of the supports and catalysts in the nanoscale to follow the procedures of synthesis and evolution in operation.

Inmobilization of heavy metals by synthetic high-charged organomicas: Test at laboratory scale

Investigador Principal: María Dolores Alba Carranza

Periodo: 16-05-2014 / 16-02-2019

Organismo Financiador: Junta de Andalucía

Código: P12-FQM-567

Componentes:

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

The focus of the project addresses the environmental technological requirement to develop advanced methods for removing pollutants. The interest and efforts to develop new technologies aimed at more efficient treatment in detention and revaluation of hazardous waste is increasing in R & D plans. It is in this scenario where this project should be framed and in particular in the framework of the management of heavy metal cations, issue of high public interest in this decade.

Since the second half of the twentieth century, humanity has faced a huge scientific and technological development that is responsible for increased environmental pollution. As an example, we can mention two problems that are currently of concern and action of the Andalusian: Andalusian coastal pollution and urban wastewater. Therefore, this is a complex problem that pollutants sources are varied of origin and routes followed by various pollutants are diverse and, frequently, it is beyond the control necessary to avoid urban undesirable effects on the natural environment and. Therefore, a basic level research is demaned to implement the necessary mechanisms for the immobilization of such harmful cations.

The objectives and scope of this project are based on advances made by other research groups in the management of these types of contaminants and the latest research conducted by the research team that allowed design expandable high-charged layered silicates with special properties as precursors for the retention of harmful residues. Therefore, it is proposed in this project the organofunzionalization of such synthetic micas with thiol groups or alkylammonium cations of varying chain length and evaluation of its adsorption capacity and irreversible retention of heavy metals.

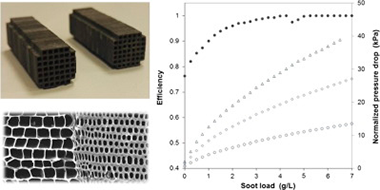

Bio-ceramics for diesel engine particulate filters

Investigador Principal: Julián Martínez Fernández / Ricado Chacartegui

Periodo: 01-01-2014 / 31-12-2016

Organismo Financiador: Ministerio de Economía y Competitividad

Código: MAT2013-41233-R (Programa Retos)

Componentes: José Antonio Becerra Villanueva, Alfonso Bravo León, Manuel Jiménez Melendo, Antonio Ramírez de Arellano López, Joaquín Ramirez Rico, Francisco Varela Feria

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

The importance of controlling particulate emissions from diesel engines is essential given its volume and the associated environmental and economic impact. Control systems based on modifications of the combustion process in the engine are not sufficient to meet the requirements of current regulations, less future ones, and therefore it must necessarily be employed post treatment systems such as filters. There is considerable scope for improving them both in reliability, degradation of control performance, durability, multifuel operation and cost reduction.

This project will assess the development and manufacturing of regenerative particulate filter for diesel engines to improve the current system specifications, based on a new generation of ceramic bio-derivated materials, with integrated systems for particle combustion. This objectives will be achieved integrating researchers synergies from: i ) Thermal Engines and Machines Group, GMTS , specialists in internal combustion engines ii ) Multifunctional Biomimetic Materials Group, MBM, specialists in obtaining bio-derivated porous ceramic as well as physical, chemical and microstructural characterization. In addition, the project is completed with the collaboration of companies in assessing technology and its industrial applicability.

The following research lines will be addressed:

- Determination of processing routes that enable the development of filter elements with suitable physical, and chemical properties, based on prior knowledge in bio-derivated materials and new technologies regarding the use of SiO2 gels.

- Identification of suitable catalysts and systems for its deposition.

- Manufacture of the filter elements consisting of porous support and catalyst.

- Thorough characterization of the physical, chemical and microstructural properties of interest for the application.

- Development of activation systems for the filter regeneration.

- Design and manufacturing of the filters with suitable geometry and prototype dimensions.

- Pilot unit design and study of the integration and operation of engine.

- Final design of the filter for industrial facility.Previous studies developed by MBM in these bio-derivated materials have demonstrated their potential as gas filter elements at high temperatures in coal gasification plants, which supports the likelihood of success of this project, which will address the improvements needed to develop the technology in the combustion conditions of diesel engines, under dynamic conditions in vehicles and regenerative filters.

A reduction of pollutant emissions from diesel engines would have a great environmental impact, health and economic development, with about 100 million diesel vehicles circulating in Europe and a related industry with over 2 million direct jobs and growing trend in market. This project addresses the Social Challenge 3 Horizon 2020, Secure, clean and efficient energy. In addition, using bioceramics allows replacement of metal components used today, which also aligns with the Social Challenge 5 of the Horizon 2020 in search of alternatives to essential raw materials in existing applications by reducing dependence on imports and sustainability of applications.

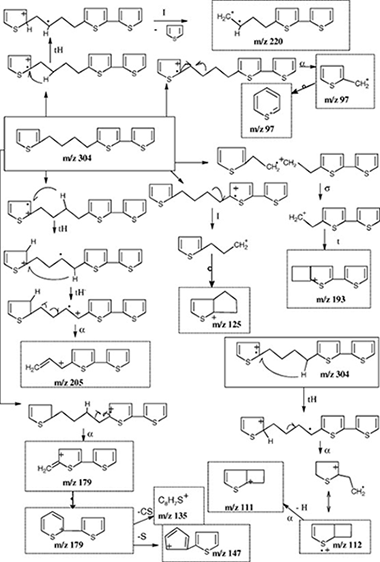

The obtention of fatty polyhydroxyalcanoate (PHA) bioplastics from peels residues of commercial fruits

Investigador Principal: José Jesús Benítez Jiménez

Periodo: 16-05-2013 / 15-05-2016

Organismo Financiador: Junta de Andalucía

Código: P11-TEP-7418 (Proyecto de Excelencia)

Componentes: Antonio Heredia Bayona, Miguel Angel San Miguel Barrera, Jaime Oviedo López, J. Alejandro Heredia Guerrero, Santiago Domínguez Meister, Daniel Aguilera Puerto, Francisco Javier Navas Martos, José Manuel de la Torre Ramírez

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

The main objective of this project is to evaluate the feasibility of scaling up a procedure to obtain fatty polyhydroxyalcanoate (PHA) bioplastics from a low-cost and abundant source like peels residues of commercial fruits. The strength of the proposal relies on the introduction of a new non-toxic and fully biodegradable polymeric material as a substitute for environmental-hostile petroleum-based plastics. The overall sustainability is extended to the use of a low-impact synthetic route and to the processing of a plant residue rather than crops intended for human or cattle feeding. The project is considered of additional interest in regions with an agricultural based economy like Andalusia and with an important environmental impact arising from the greenhouse activity. The proposal also covers the study of new and more specific applications of such bio-based fatty polyhydroxyalcanoates.

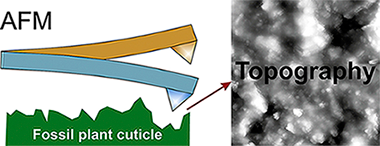

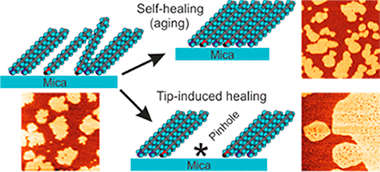

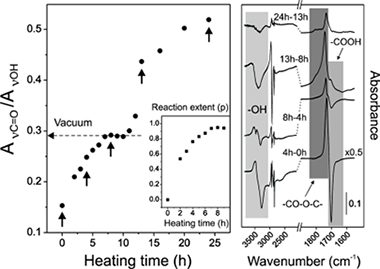

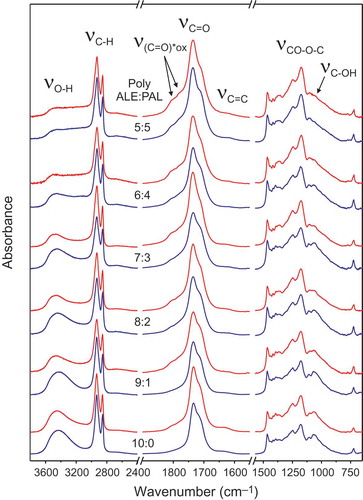

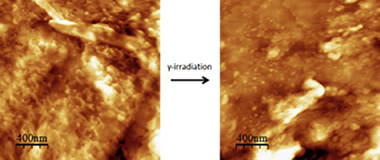

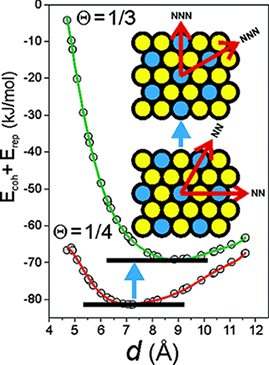

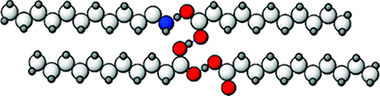

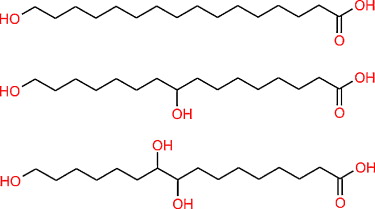

Fatty hydroxyacids molecular interactions as model for biomimetic polyester design

Investigador Principal: José Jesús Benítez Jiménez

Periodo: 01-01-2012 / 31-12-2014

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: CTQ2011-24299

Componentes: Alejandro Heredia Guerrero, Miguel Angel San Mibuel Barrera, Jaime Oviedo López, Miguel Salmerón Batalle

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

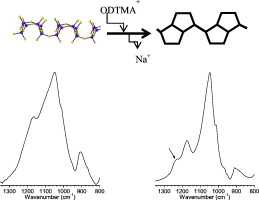

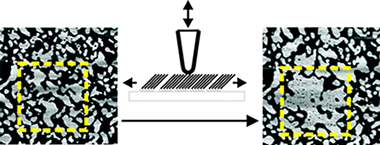

The objective of this Project is to study and characterize the specific interactions between fatty carboxylic acids molecules arising from selective hydroxylation of the alkyl chain. To address this issue, molecular self-assembled systems showing a low interaction with an atomically flat support are proposed as models. The use of low binding energy supports is to ensure the packing structure to be mainly driven by the molecule to molecule interactions rather than the molecule to substrate adsorption. These self-assembled systems will be characterized by scanning probe microscopies such as AFM and STM and infrared spectroscopy. Results will be complemented with molecular dynamics atomistic simulations. Basic information obtained from self-assembled models will be used to design the in-vitro chemical synthesis of cutin mimetic polyesters. Cutin is a non toxic, fully biodegradable barrier biopolymer present at the skin of fruits, leaves and non lignified stems of higher plants. Physical (mechanical, water permeability, ionic transport, etc…) and chemical (ester yield, controlled chemical degradation rate, etc…) properties of synthetic polyesters will be determined. Material features will be related with both, the main structure arising from the ester bonds formation and the secondary network resulting from hydrogen bonding between spare non reacted hydroxyl groups. Structure-function patterns will be used to redesign the synthesis route to obtain polymeric esters with tailored properties. To achieve this goal, both the primary and secondary structural networks will be manipulated. In the first case non hydroxylated molecules will be used to prevent ester bonding propagation. To modify hydrogen bonding crosslinking, additives with selected hydroxylation (primary or secondary) will be employed. The final motivation of this research is to explore the applicability of such mimetic polyester as substitutes for the highly contaminant hydrocarbon based plastics.

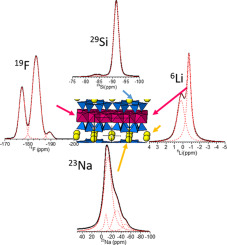

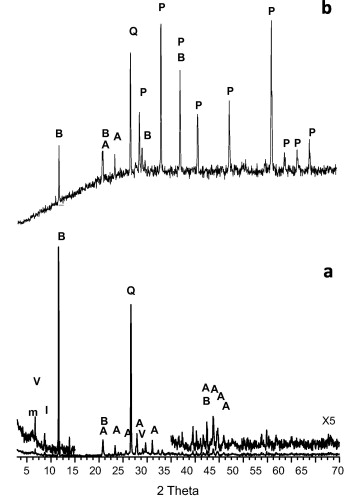

Immobilization of cations in high-density charge confined spaces: management of harmful cations wastes

Investigador Principal: María Dolores Alba Carranza

Periodo: 01-01-2011 / 31-12-2013

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: CTQ2010-14874/BQU

Componentes: Miguel Angel Castro Arroyo, Maria del Mar Orta Cuevas, Mery Carolina Pazos Zarama, Said ElMrabet, Esperanza Pavón González, Maria Villa Alfageme, Santiago Medina Carrasco, Ana Isabel Becerro Nieto, Alberto José Fernández Carrión

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

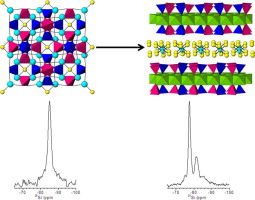

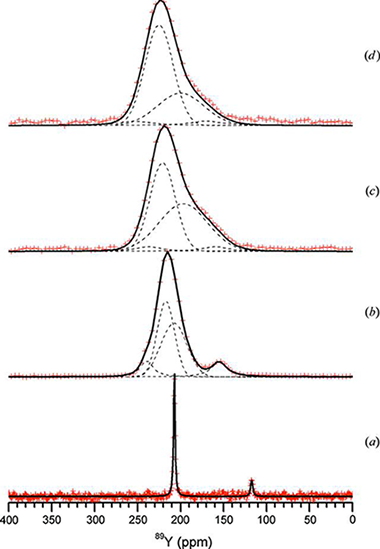

The central subject of this Project deals with the environmental technological exigency for development of advanced technologies for the elimination of polluting agents. The interest and the effort dedicated to the development of new technologies that allow more effective treatments of retention and new procedures of valorisation is increasing in numerous R&D plans in the last years. It is in this scene where the present proposal must be fitted and circumscribed into two experimental basic findings: designing expansible high layer charge silicates with a controlled distribution of active centres, which can be effective materials for the retention of hazardous and radioactive wastes, and obtaining insoluble disilicate phases in smooth conditions, appropriate for the immobilization of such species. This objective represents a qualitative change in the work that has been developed up to now in relation to the elimination of radioactive and toxic wastes as well as in the application of the methodology to silicate systems. The objectives are adapted, in general, to the high-priority lines of Basic Investigation of Chemistry, in the area of Inorganic Chemistry (Solid State Chemistry) and Environmental Chemistry in particular but, in spite of its basic character, the Project is adapted to diverse lines of investigation of Oriented Chemistry and it is supported by different EPOs (ENRESA, BEFESA and ALQUIMIA). These objectives, of eminent basic character, require the development of techniques of sophisticated analysis like advanced Solid State NMR, X-ray diffraction, under conditions of controlled pressure and temperature or gamma spectroscopy of low counts. This fact fits to the particular objective of the Chemistry Area of “using the instrumental and experimental technology for the study of materials” and with objective O2.5 (Enhance the availability of interdisciplinary infrastructures and sharing use of them) of the R+D+I National Plan 2008-2011. A guarantee of this proposal is that, in a first place, the Research Group (RG) has recently published the synthesis of expansible mica using a method that allows obtaining the desired layer charge in the material; secondly, the RG has a wide experience in the design of synthesis mechanisms of silicates as demonstrated by the number of papers published on this area during the last decade, and, finally, the RG has developed useful methodologies for the present Project in collaboration with other Groups with which it maintains a narrow scientific relationship.

Bioener: Aplicación de tecnologías biomiméticas a sistemas energéticos

Investigador Principal: Julián Martínez Fernández

Periodo: 01-01-2010 / 31-12-2012

Organismo Financiador: Junta de Andalucía

Código: P09-TEP-5152 (Proyecto de Excelencia)

Componentes: Manuel Jiménez Melendo, Antonio De Arellano-López, Alfonso Bravo León, F.M. Varela Feria

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

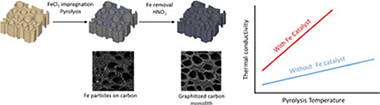

Technological advances have made possible to diversify and optimize energy produc-tion, which in turn has motivated the development of new ways to store energy. In particular, as production methods diversify, it is necessary to develop new materials for energy storage, both large scale and in consumer devices and transportation. This is especially important in the context of higher penetration of renewable energies, which often depend on climatological conditions and require ways to store excess energy at production peaks, so it can be used when production decreases. In parallel to this strategy and to reduce the share of fossil fuels in the overall energy production, it is necessary to increase the efficiency of conventional power generation sys-tems, for example by increasing material’s life and operating temperatures, for example in gas turbine systems, among others. The development of materials for high temperature applications, especially ceramics, has been traditionally linked to the search for increased efficiency of power generation systems. Ceramic materials, due to their high melting point, good creep resistance and resistance to corrosion, are seen as candidates for application in chemically aggressive environments at temperatures over 1000 ºC. Carbides and nitrides in particular are being studied extensively for this kind of applications. Porous ceramics are also of great interest in energy applications, such as heat exchangers or syngas filtration systems, among others. Among active research lines in the development of new materials for energy storage, electrochemical storage is expected to have the largest impact in the end consumer, as the design of high capacity batteries and electrochemical capacitors is key for the viability of tech-nologies such as plug-in electric cars. For this reason, research into new materials for electro-chemical storage has become a strong focal point among the scientific community and consti-tutes one to the great technological challenges of today. Biomorphic silicon carbide (bioSiC) is a ceramic material obtained by reactive infiltra-tion of carbon performs derived by pyrolysis of natural precursors. The precursor, usually wood, is rough-machined and then converted to carbon by pyrolysis in a controlled atmos-phere at high temperatures. The result is a macroporous carbon material (bioC) with a micro-structure that closely resembles that of the original precursor. This carbon template is then machined to near net shape and is melt reacted with silicon either in liquid or vapor phase to obtain a SiC composite with some residual Si that shows excellent thermomechanical proper-ties and a microstructure that closely mimics that of the original wood precursor. Tailoring the material’s properties is possible by adequate selection of the precursor, which determines the microstructure and thus the properties of the bioSiC. It is also possible to remove the remaining silicon through chemical etching to obtain a macroporous SiC material which can then be reinfiltrated to create novel composites and cermets, such as bioSiC/Al or bioSiC/Cu. The prospect of producing macroporous carbon materials with controlled nanoporosi-ty is interesting for electrochemical applications, as it would be possible to infiltrate or coat macropores with a second phase the provides additional function, for instance in three dimensional lithium batteries [3, 20] or carbon/oxide supercapacitors [4, 5]. In this way, the development of new carbon materials with controlled structure and porosity could open the door to novel architectures and designs for devices able to store larger amounts of energy. Most nanoporous carbon materials used nowadays are obtained through activation of carbons made from pyrolysis of synthetic precursors [21], although in the last years carbide-derived carbons have been the subject of great interest [22, 23, 24]. It is possible to obtain high-purity nanoporous carbon through high temperature chlorination of metallic carbides, which rank among the best carbon materials for electrochemical applications. In this direction, is has already been shown that carbides obtained from natural precursors, such as bioSiC are viable precursors to carbide-derived carbons [25]. This proposal’s aim is two-fold: on one side, the bioC processing will be studied in de-tail, paying special attention to precursor selection and to the possibility of introducing differ-ent atmospheres during the pyrolysis process, such as CO2 or water vapor, that promote nanoporosity in the material. The effect of processing parameter in the degree of crystallinity, nanoporosity, crystallite size and structure of the resulting carbon material will be assessed. The possibility of promoting carbon graphitization through the use of different catalysis in the pyrolysis process will be studied. The resulting carbon’s microstructure and physical properties will be studied and correlated to the processing parameters. On the other side, the effect of the aforementioned treatments on the bioSiC material will be studied, and the possibility of obtaining novel cermets in-situ, such as bioSiC/Al, bioSiC/Ti, through melt infiltration, will be assessed. In a last step, the possibility of obtained carbon materials with enhanced structure from the ceramic carbides will be explored.

Microestructura y deformación plástica a alta temperatura de óxidos eutécticos basados en Al2O3. Superplasticidad

Investigador Principal: Manuel Jiménez Melendo

Periodo: 01-01-2010 / 31-12-2012

Organismo Financiador: Ministerio de Ciencia y Tecnología

Código: MAT2009-13979-C03-01

Componentes: Julián Martínez Fernández, Antonio Ramírez De Arellano-López, Alfonso Bravo León, Caroline Clauss Klamp, F.M. Varela Feria, C. Vaquero Aguilar

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

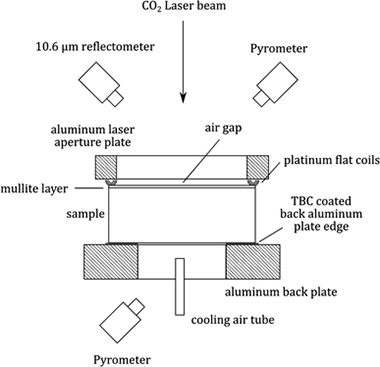

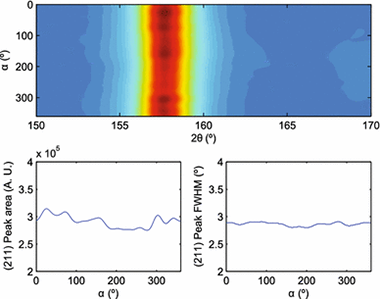

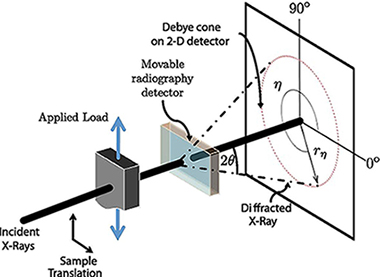

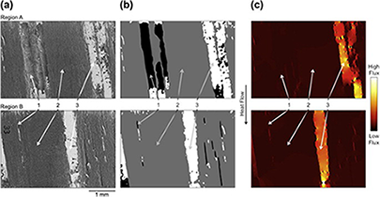

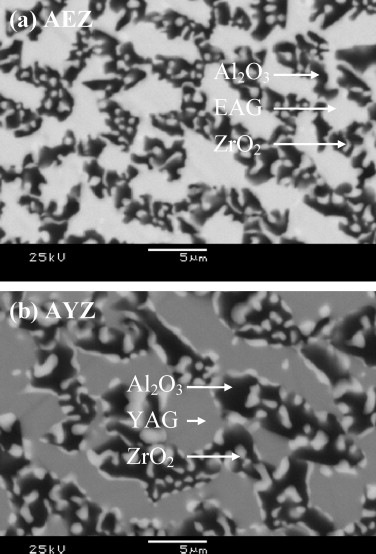

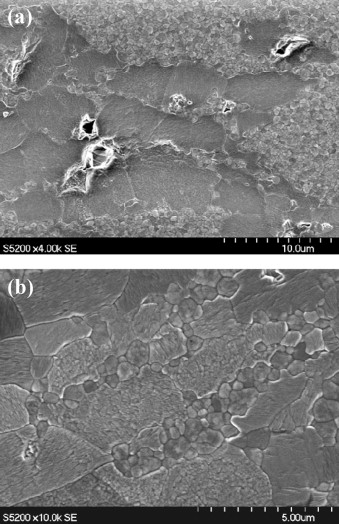

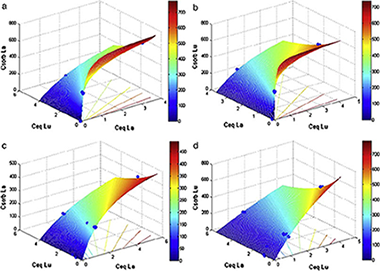

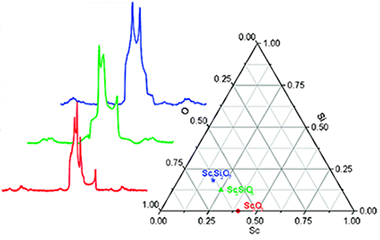

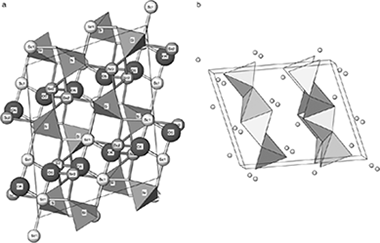

This research addresses to produce binary and ternary oxide eutectics –specifically, Al2O3/ZrO2, Al2O3/Y3Al5O12(YAG), Al2O3/ZrO2/YAG and Al2O3/SiO2/ZrO2, zirconia being stabilized with different amounts of Y2O3– with well-controlled microstructures in the micro- to nanometric range for structural and thermal applications in efficient-enhanced power generation and conversion systems: fuel cells, chemical and high-temperature gas cooled reactors, thermal barriers of steels and super alloys in gas turbines and diesel engine components, etc. These materials are very attractive because of their excellent properties: high melting point, low density, thermal conductivity and chemical reactivity, and superior mechanical performance at both low and high temperature: mechanical strength close to 5 GPa at room temperature, and high creep, wear and erosion resistance. Very recently, superplasticity has been discovered in nanosized materials by the applicant team. Oxide eutectics will be produced by laser-assisted processing techniques in three configurations: bulk, plates (on ceramic and metallic substrates) and multilaminates. For the later configuration, microarquitectures with optimized residual stresses will be designed for enhanced mechanical and thermal performance. The residual stresses will be investigated by using piezo- and Raman spectroscopy, and the data compared to numerical predictions. Laser techniques will be also used to modify the microstructure of conventional ceramic coatings deposited on metallic engine components by Air Plasma Spray, and for machining of ceramic components to obtain a given functional geometry or to modify the external surfaces for improved wear behavior. One of the main goals of this Project is to produce materials with nanosized phases in order to achieve superplasticity (which contrasts with the superior creep resistance of mi-crosized materials). This capability opens the possibility of using superplastic joining and forming as processing methods for complex pieces with near net shape, recovering back its characteristic resistance after thermal treatments. The mechanical properties (flexural and compression resistance, elastic modulus, hardness, toughness and wear) will be evaluated from room temperature up to 1950 K in air as well as under other different environmental atmospheres in order to investigate their effect in the mechanical behavior or material degradation. A significant part of the Project is the structural and microstructural characterization of the as-received materials, and their evolution during mechanical tests. Such an investigation is critical to establish relationships between the experimental mechanical behavior (necessary for engineering designs) and the microstructural and processing parameters. To this end, techniques of optical (particularly confocal), electron (image, microanalysis and diffraction) and atomic force microscopy, and X-ray diffraction with texture facilities will be used. Mechanical and microstructural data will feedback the fabrication process in order to obtain materials with tailored properties for specific applications.

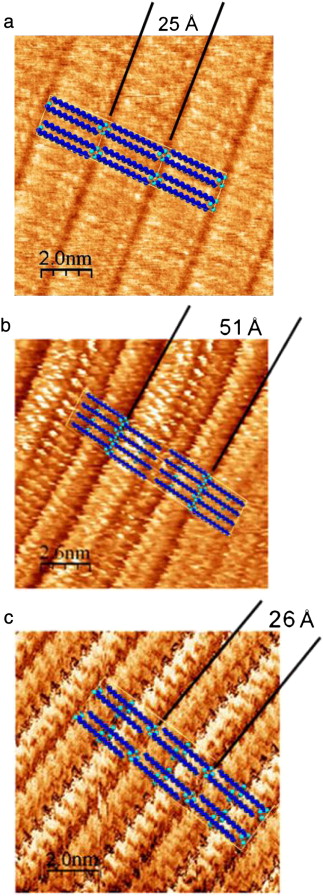

Structure, packing and tribology of Fatty Self-assembled monolayers of Alkylamines

Investigador Principal: José Jesús Benítez Jiménez

Periodo: 01-01-2009 / 31-12-2011

Organismo Financiador: Ministerio de Ciencia y Tecnología

Código: CTQ2008-00188

Componentes: Miguel Salmerón, Eduardo Garzón Garzón, Pedro J. Sánchez Soto, J. Alejandro Heredia Guerrero

Grupo de Investigación:

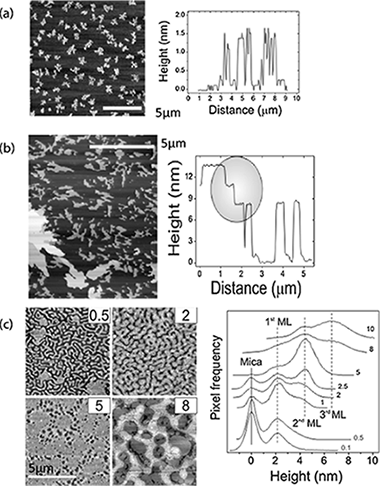

The aim of this research project is to study the contribution of molecular scale events to the tribological properties of self-assembled monolayers of alkyl molecules. The amount of topographic and frictional AFM data available on typical self-assembled systems such as thiols on gold and silanes on mica is very extensive. Here, we propose alkylamines on mica as a new self-assembled system. The reason is that the weaker interaction between the amino end group and mica, if compared with S-gold and silane-mica, leads to a less effective molecular packing. The ability to control the quality of molecular packing by tunning the preparation conditions is a good model to test the contribution of defects to friction. Molecular resolution using contact AFM is not possible on alkylamine self-assembled monolayers, so there is a lack of structural information on this system. The new methodology described in this project proposes the use of Scanning Polarization Force Microscopy (SPFM) to address this issue based on the high polarization signal contrast between mica and self-assembled layers. Furthermore, the high sensitivity of SPFM to the presence of water molecules filling vacancies, can be used to evaluate the quality of the molecular packing by monitoring the screening effect exerted by the self-assembled layer. Consequently, the study of both, the frictional and the SPFM properties of self-assembled monolayers of alquilamines, are complementary to describe the contribution of defects to friction.

Ceramic composites and low-dimensional phases to waste management

Investigador Principal: Miguel Angel Castro Arroyo

Periodo: 01-10-2007 / 30-09-2010

Organismo Financiador: Ministerio de Educación y Ciencia

Código: CTQ2007-63297

Componentes: Alba, M.D., Alvero, R., Becerro, A.I., Chain, P., Escudero, A., Naranjo, M., Trillo, J.M.

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

The main objective of this Project is obtaining composite materials from especially designed expansible and high layer charge laminar silicates containing low dimensional phases with effective activity for the retention and immobilization of toxic and dangerous wastes. The main innovating aspect of the Project arises, on one hand, from the confluence of the studies that the research team has performed with researchers from University of Cambridge (United Kingdom) within the development of the current national project. On the other hand, it arises from the action of reunification of the researchers who participate in a unique multidisciplinary project in the border of the basic chemistry of silicates in connection with the waste management. The proposed hypothesis, elaborated from the results obtained by the research team during the last decade, states that the effectiveness of the elimination of polluting agents by layered aluminosilicates is controlled by the structural disposition and the composition of the low dimensional phases originated during the treatments. Methodology is not limited to synthesis of the composite materials and its characterization, and it incorporates a measurement of the potential which they would represent in the treatment of wastes, essentially based on some organic polluting agents and heavy, toxic and radioactive cations. The development of the Project will affect the relations of the research team with Research Groups of the University of Bayreuth (Germany) and Cambridge (United Kingdom) and the multidisciplinary character of the Project and the noticeable academic and educational character of the team can be considered a guarantee of its high formative capacity.

Inmobilization of toxic and radioactive wastes by silicates

Investigador Principal: Miguel Angel Castro Arroyo

Periodo: 28-2-2007 / 1-3- 2010

Organismo Financiador: Junta de Andalucía

Código: P06-FQM-02179

Componentes: Alba, M.D., Alvero, R., Becerro, A.I., Chain, P., Escudero, A., Naranjo, M., Pavón, E., Trillo, J.

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

In The present Project tries to use high-charged silicates, which are designed under procedures that allow controling the quantity and distribution of the tetrahedral active centers. They will be submitted to a set of chemical soft treatments in order to inmobilize toxic elements. This project will be carried out in collaboration with BEFESA and ENRESA companies. Firstly, the effect that the experimental variables involved in the procedure of synthesis exert on the distribution of the active centers of the materials will be analyzed. In the second stage, the synthetic silicates will be treated under soft hydrothermal conditions with solutions containing carefully selected toxic and radioactive elements. Finally, the degree of retention of these elements in the new obtained phases will be estimated. The Research Team (R.T.) will incorporate an experimental methodology developed by itself that includes the combined employment of Nuclear Magnetic Resonance of Solids, X-ray Diffraction, X-rays Fluorescence and Microfluorescence, which will give information of the long range order and the local environment of the active centers of the residues, responsible of it dangerousness. It will have to give direct and not yet available information of the final mechanism of fixation, which is the main objective of this Project. The expected Results will bring basic useful information about the mechanisms of interaction of metallic ions with the framework of expansible aluminosilicates and its relation with the local arrangement of their atoms. Moreover, it will bring a useful knowledge allowing to develop new suitable procedures for immobilization of industrial waste, in collaboration with the companies of the sector, which marks the innovative character of the Project.

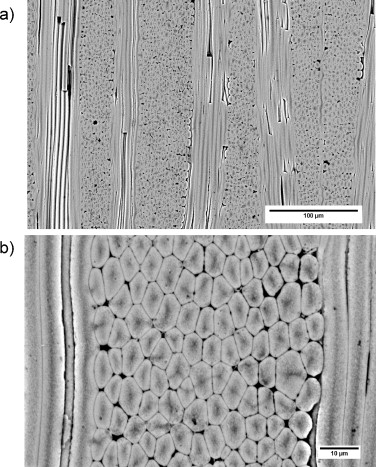

New Bio-ceramization processes applied to vegetable hierarchical structures

Investigador Principal: Julián Martínez Fernández

Periodo: 01-10-2006 / 30-09-2010

Organismo Financiador: Unión Europea

Código: STRP 033277 TEM-PLANT

Componentes: Ramírez de Arellano-López, A., Jiménez, M., Marrero, M., Clauss, M., Bravo, A., Quispe, J.J.

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente

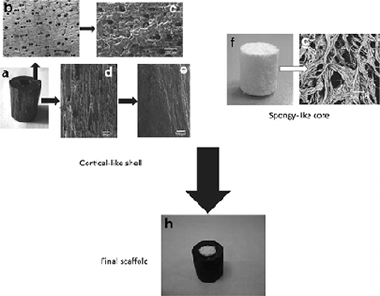

TEM-PLANT project focuses on the development and application of breakthrough processes to transform plant-derived hierarchical structures into templates for the exploitation of innovative biomedical devices with smart anisotropic performances and advanced biomechanical characteristics, designed for bone and ligament substitution. The TEM-PLANT project primary addresses the nano-biotechnologies area and will push the current boundaries of the state-of-the-art in production of hierarchical structured biomaterials. By combining biology, chemistry, materials science, nanotechnology and production technologies, new and complex plant transformation processes will be investigated to copy smart hierarchical structures existing in nature and to develop breakthrough biomaterials that could open the door to a whole new generation of biomedical applications for which no effective solution exists to date.

Starting from suitably selected vegetal raw material, ceramization processes based on pyrolysis will be applied to produce carbon templates, which will be either infiltrated by silicon to produce inert SiC ceramic structures or exchanged by electrophoresis deposition to produce bioresorbable ceramics. For ligament yielding two processes will be developed: pH-controlled and electrophoresis-controlled fibration to generate fibrous collagenous cords with high tensile strength and wear-resistance.

2023

2023

Materiales de Diseño para la Energía y Medioambiente

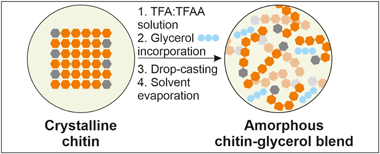

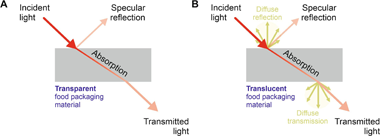

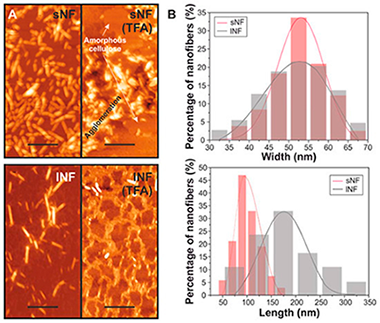

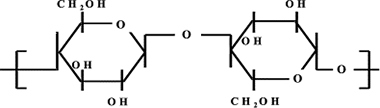

Plasticized, greaseproof chitin bioplastics with high transparency and biodegradability

Heredia-Guerrero, JA; Benitez, JJ; Porras-Vazquez, JM; Tedeschi, G; Morales, Y; Fernandez-Ortuno, D; Athanassiou, A; Guzman-Puyol, SFood Hydrocolloids, 145 (2023) 109072

Show abstract ▽

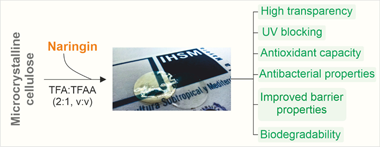

A mixture of trifluoroacetic acid:trifluoroacetic anhydride (TFA:TFAA) was used to dissolve chitin from shrimp shells. Free-standing films were prepared by blending the chitin solution and glycerol at different percentages, followed by drop-casting, and the complete evaporation of the solvents. After this process, the chitin matrix showed an amorphous molecular structure, as determined by X-ray diffraction. Optical, mechanical, thermal, and antioxidant properties were also thoroughly investigated. The incorporation of glycerol induced a plasticizing effect on the mechanical response of films and improved their transparency. In addition, hydrodynamic and barrier properties were determined by contact angle and water vapor/oxygen transmission rates, respectively, and revealed typical values of other polysaccharides. These bioplastics also presented an excellent greaseproof behavior with the highest degree of oil repellency as determined by the Kit test. Moreover, the overall migration was evaluated by using Tenax & REG; as a dry food simulant and levels were compliant with European regulations. Their antifungal properties were tested using Botrytis cinerea as a model. Biodegradability was also determined by measuring the biological oxygen demand in seawater. Degradation rates were high and similar to those of other fully-degradable materials.

December, 2023 | DOI: 10.1016/j.foodhyd.2023.109072

Materiales de Diseño para la Energía y Medioambiente

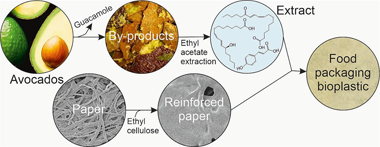

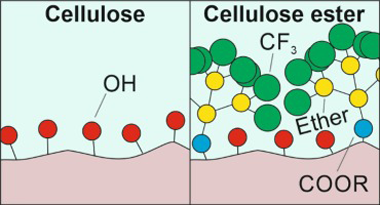

Incorporation of bioactive compounds from avocado by-products to ethyl cellulose-reinforced paper for food packaging applications

Acquavia, MA; Benitez, JEJ; Bianco, G; Crescenzi, MA; Hierrezuelo, J; Grife-Ruiz, M; Romero, D; Guzman-Puyol, S; Heredia-Guerrero, JAFood Chemistry, 429 (2023) 136906

Show abstract ▽

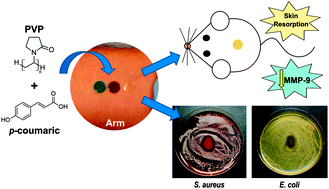

Reinforced films were fabricated by impregnating paper in ethyl cellulose solutions. After solvent evaporation, the infused ethyl cellulose acted as binder of the paper microfibres and occupied the pores and cavities, thus improving the mechanical and barrier properties. To prepare active films, avocado by-products from guacamole industrial production were extracted in ethyl acetate. Then, the extract (optimized to be rich in phenolic compounds and flavonoids and mainly composed by lipids) was incorporated to the paper reinforced with the highest content of ethyl cellulose. In general, the addition of the avocado by-products extract decreased the water uptake and permeability, improved the wettability, and increased the biodegradability in seawater and the antioxidant capacity. In addition, these films acted as barriers and retainers for Escherichia coli and Bacillus cereus. The potentiality of these materials for food packaging was demonstrated by low overall migrations and a similar food preservation to common low-density polyethylene.

December, 2023 | DOI: 10.1016/j.foodchem.2023.136906

Materiales de Diseño para la Energía y Medioambiente

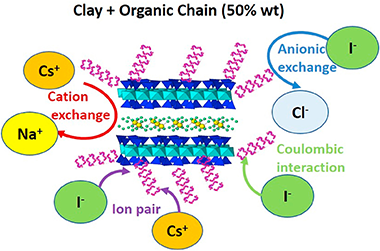

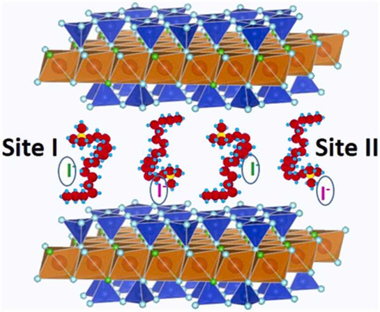

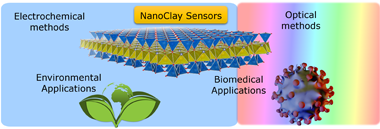

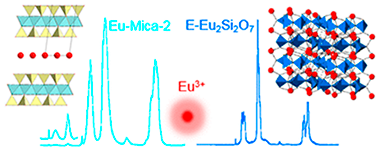

A technological approach based on engineered nanoclay composites for cesium and iodine retention

Osuna, FJ; Pavon, E; Alba, MDChesmosphere, 341 (2023) 140128

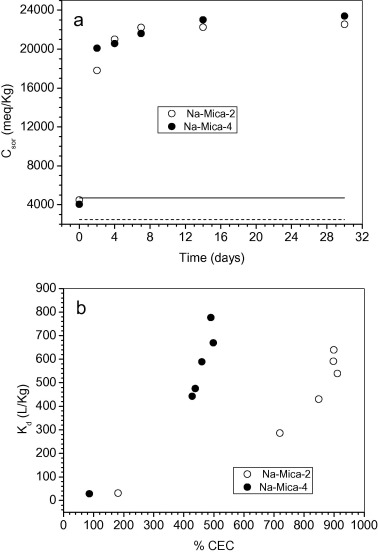

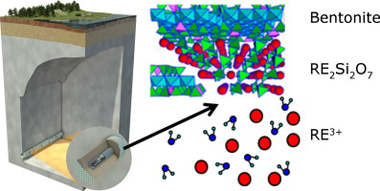

Show abstract ▽

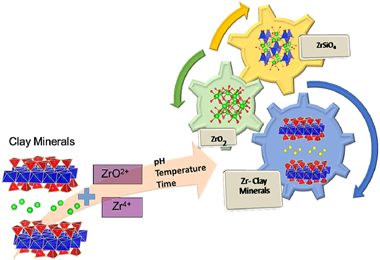

The development of effective and environmentally friendly methods for separating hazardous radionuclides from waste poses a significant technological challenge. 137Cs and 131I are among the most important radionuclides discharged into the environment by nuclear power plants. One of the best ways to eliminate them involves adsorption on clay minerals. In this regard, studies have demonstrated that organofunctionalized clay minerals are effective adsorbents. Thus, this study investigates the capability of organofunctionalized synthetic design clay minerals to jointly eliminate cesium and iodine. The adsorbents studied are a range of organofunctionalized clay minerals with alkylammonium cations of different alkyl chain lengths (2, 3 and 18) and some physical mixtures of raw clay minerals and octadecylammonium compounds. Organofunctionalized synthetic swelling highly charged micas are effective adsorbents for the simultaneous adsorption of cesium and iodine. In addition, the optimal system is a mixture of Na-M4 with octadecylammonium (50% w/w).

November, 2023 | DOI: 10.1016/j.chemosphere.2023.140128

Materiales de Diseño para la Energía y Medioambiente

Biodegradability Assessment of Prickly Pear Waste-Polymer Fibers under Soil Composting

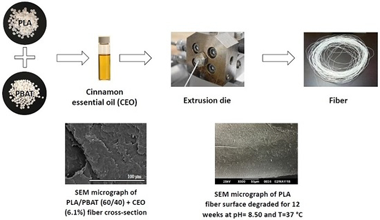

Correa-Pacheco, ZN; Bautista-Baños, S; Benítez-Jiménez, JJ; Ortega-Gudiño, P; Cisneros-López, EO; Hernández-López, MPolymers, 15 (2023) 4164

Show abstract ▽

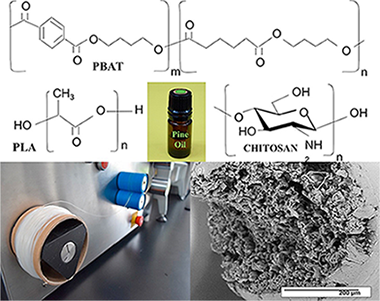

Nowadays, solving the problems associated with environmental pollution is of special interest. Therefore, in this work, the morphology and thermal and mechanical properties of extruded fibers based on polylactic acid (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) added to prickly pear flour (PPF) under composting for 3 and 6 months were evaluated. The highest weight loss percentage (92 +/- 7%) was obtained after 6-month degradation of the PLA/PBAT/PPF/CO/AA blend, in which PPF, canola oil (CO), and adipic acid (AA) were added. Optical and scanning electron microscopy (SEM) revealed structural changes in the fibers as composting time increased. The main changes in the absorption bands observed by Fourier transform infrared spectroscopy (FTIR) were related to the decrease in -C=O (1740 cm-1) and -C-O (1100 cm-1) groups and at 1269 cm-1, associated with hemicellulose in the blends with PPF. Differential scanning calorimetry (DSC) showed an increase in the cold crystallization and melting point with degradation time, being more evident in the fibers with PPF, as well as a decrease in the mechanical properties, especially Young's modulus. The obtained results suggest that PPF residues could promote the biodegradability of PLA/PBAT-based fiber composites.

October, 2023 | DOI: 10.3390/polym15204164

Materiales de Diseño para la Energía y Medioambiente

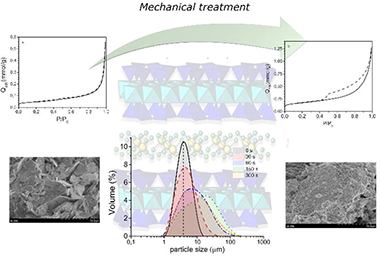

Mechanical treatments on design powder ceramic materials: Insight into the textural and structural changes

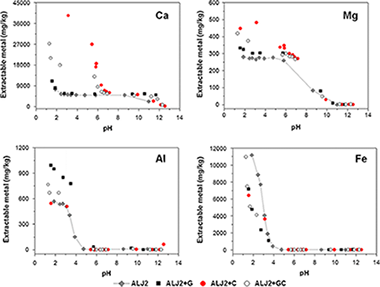

Osuna, FJ; Fernández, M; Pavón, E; Sánchez, RMT; Alba, MDAdvanced Powder Technology, 34 (2023) 104189

Show abstract ▽

Mechanical treatment of porous ceramics, such as porous clay minerals, is a crucial step in ceramic processing. Among clay minerals, design swelling brittle micas have shown exceptional properties for further applications, although they exhibit low surface area and porosity. But, their mechanical activation could improve their textural properties and deserves to be investigated. Thus, the aim of this work was to evaluate the effects of gradual grinding in their surface and framework. At short grinding times, the surface area increases and mesoporous and microporous are generated. Long grinding time provokes particle agglomeration with the consequent change in their colloidal stability. At bulk level, framework defects are observed in both tetrahedral and octahedral sheets and increase with the total layer charge.

October, 2023 | DOI: 10.1016/j.apt.2023.104189

Materiales de Diseño para la Energía y Medioambiente

Sustainable Integration of Zinc Oxide Nanoparticles: Enhancing Properties of Poly(ε-Caprolactone) Electrospun Nanofibers and Cast Films

Abdullah, JAA; Benítez, JJ; Guerrero, A; Romero, ACoatings, 13 (2023) 1665

Show abstract ▽

This study investigated the impact of adding zinc oxide nanoparticles (ZnO-NPs) to electrospun membranes and cast films made of poly(epsilon-caprolactone) (PCL). The physicochemical, mechanical, and morphological properties of the samples were analyzed. Physicochemical parameters included water contact angle (WCA), water vapor transmission rate (WVTR), permeance, water vapor permeability (WVP), light transmission (T-600), and transparency (T). Mechanical properties, such as maximum stress (6(max)), elongation (epsilon(max)), and Young's modulus (MPa), were also evaluated. Morphological properties were analyzed in terms of thickness, dispersion, and surface roughness (measured by the arithmetic (Ra) and quadratic (Rq) averages). The crystallinity and melting point, as well as the functional DPPH center dot scavenging percentage (SP%), were also studied. The results showed that adding 1 wt% ZnO-NPs improved the water barrier properties of PCL membranes and films, increasing WCA by 1%-6% and decreasing WVTR by 11%-19%, permeance by 34%-20%, and WVP by 4%-11%, respectively. The T-600 values of PCL/ZnO-NPs membranes and films were 2-3 times lower than those of neat PCL samples, indicating improved optical properties. The mechanical properties of the composite membranes and films also improved, with 6(max) increasing by 56%-32% and Young's modulus increasing by 91%-95%, while epsilon(max) decreased by 79%-57%. The incorporation of ZnO-NPs also increased the thickness and surface roughness of the samples. The SP% of PCL/ZnO-NPs increased by almost 69%, demonstrating the beneficial effects of ZnO-NPs on the system. These findings suggest that incorporating ZnO-NPs into PCL membranes and films can enhance their properties, making them well suited for various applications, such as those within the realm of materials science and nanotechnology.

October, 2023 | DOI: 10.3390/coatings13101665

Materiales de Diseño para la Energía y Medioambiente

The Role of Protective Surface Coatings on the Thermal Stability of Delithiated Ni-Rich Layered Oxide Cathode Materials

Reissig, F; Ramirez-Rico, J; Placke, TJ; Winter, M; Schmuch, R; Gomez-Martin, ABatteries-Basel, 9 (2023) 245

Show abstract ▽

To achieve a broader public acceptance for electric vehicles based on lithium-ion battery (LIB) technology, long driving ranges, low cost, and high safety are needed. A promising pathway to address these key parameters lies in the further improvement of Ni-rich cathode materials for LIB cells. Despite the higher achieved capacities and thus energy densities, there are major drawbacks in terms of capacity retention and thermal stability (of the charged cathode) which are crucial for customer acceptance and can be mitigated by protecting cathode particles. We studied the impact of surface modifications on cycle life and thermal stability of LiNi0.90Co0.05Mn0.05O2 layered oxide cathodes with WO3 by a simple sol-gel coating process. Several advanced analytical techniques such as low-energy ion scattering, differential scanning calorimetry, and high-temperature synchrotron X-ray powder diffraction of delithiated cathode materials, as well as charge/discharge cycling give significant insights into the impact of surface coverage of the coatings on mitigating degradation mechanisms. The results show that successful surface modifications of WO3 with a surface coverage of only 20% can prolong the cycle life of an LIB cell and play a crucial role in improving the thermal stability and, hence, the safety of LIBs.

April, 2023 | DOI: 10.3390/batteries9050245

Materiales de Diseño para la Energía y Medioambiente

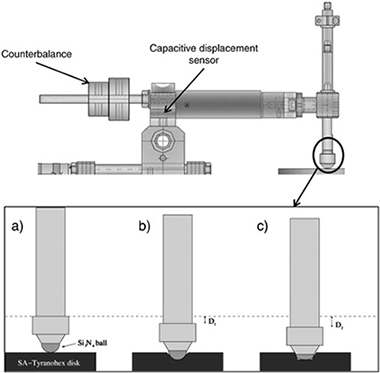

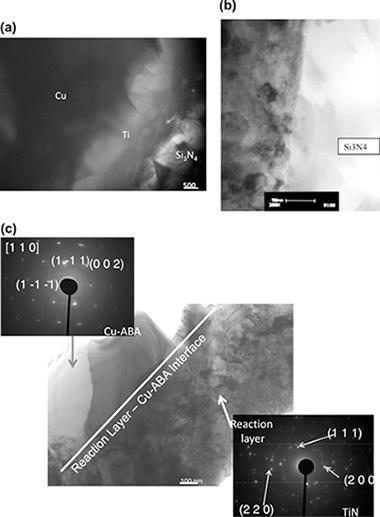

Effect of Mo and W interlayers on microstructure and mechanical properties of Si3N4-nickel-base superalloy joints

Singh, M; Fernandez, JM; Asthana, R; Ramirez-Rico, J; Valera-Feria, FMInternational Journal of Applied Ceramic Technology (2022)

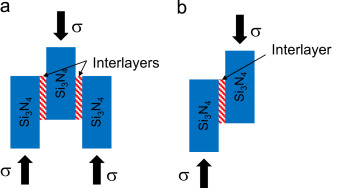

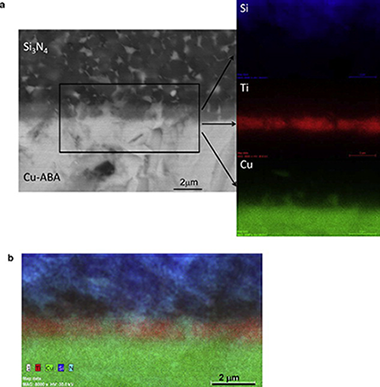

Show abstract ▽

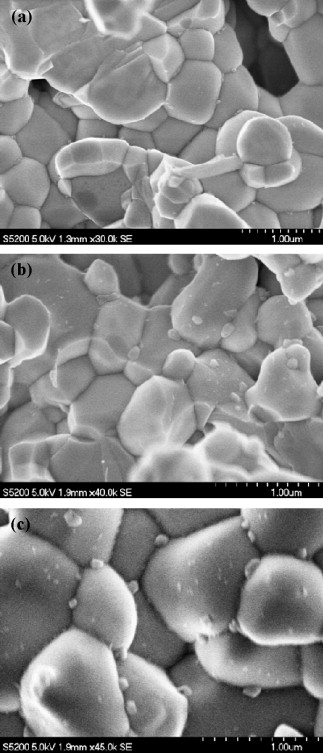

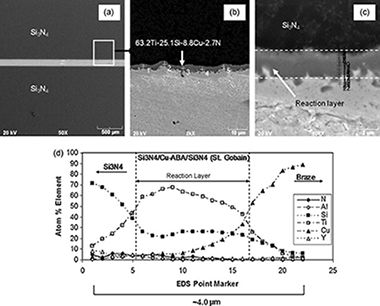

Si3N4/nickel-base superalloy (Inconel-625) and Si3N4/Si3N4 joints with refractory metal (W and Mo) interlayers were vacuum brazed using a Ti-active braze Cu-ABA (92.75Cu-3Si-2Al-2.25Ti) at 1317 K for 30 min with the following interlayered arrangements: Si3N4/Mo/W/Inconel and Si3N4/Mo/W/Si3N4. The joints exhibited Ti segregation at the Si3N4/Cu-ABA interface, elemental interdiffusion across the joint interfaces, and sound metallurgical bonding. Knoop microhardness profiles revealed hardness gradients across the joints that mimicked the interlayered arrangement. The compressive shear strength of Si3N4/Si3N4 joints both with and without W and Mo layers was similar to 142 MPa but the strength of Si3N4/Inconel joints increased from similar to 9 MPa for directly bonded joints without interlayers to 53.5 MPa for joints with Mo and W interlayers.

March, 2023 | DOI: 10.1111/ijac.14266

Materiales de Diseño para la Energía y Medioambiente

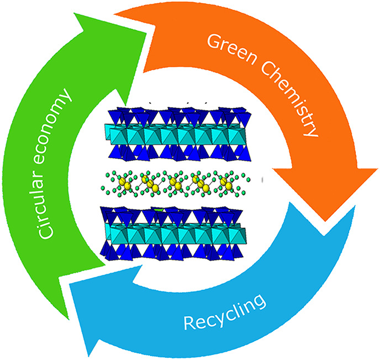

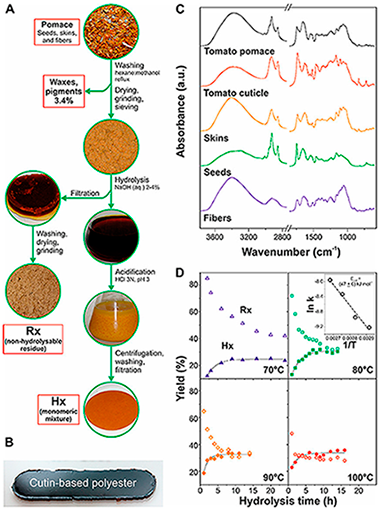

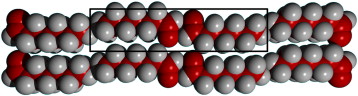

Bio-based lacquers from industrially processed tomato pomace for sustainable metal food packaging

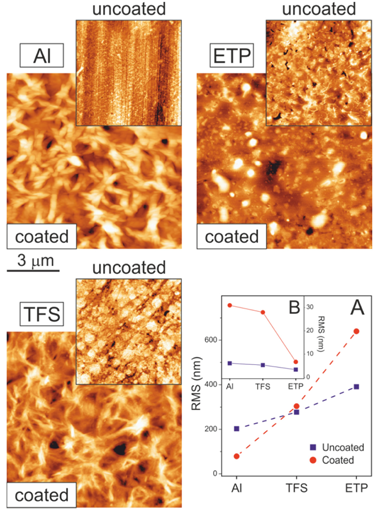

Benitez, JJ; Ramirez-Pozo, MC; Duran-Barrantes, MM; Heredia, A; Tedeschi, G; Ceseracciu, L; Guzman-Puyol, S; Marrero-López, D; Becci, A; Amato, A; Heredia-Guerrero, JAJournal of Cleaner Production, 386 (2023) 1356836

Show abstract ▽

Bio-based lacquers prepared from an underutilized tomato processing residue such as pomace have been investigated as sustainable alternatives to bisphenol A (BPA)-based coatings for metal food packaging. The fabrication methodology consisted of a two-step process: spray-coating of a paste of the lipid fraction of tomato pomace with a mixture ethanol:H2O (3:1, v:v) on common metal substrates, used for food canning, such as aluminum (Al), chromium-coated tin-free steel (TFS), and electrochemically tin-plated steel (ETP), followed by the self melt-polycondensation of such lipid fraction. The polymerization reaction was conducted at 200 degrees C for different times (10, 20, 30, 40, 50, and 60 min) and was monitored by specular infrared spectroscopy, resulting in maximum degrees of esterification of-92% for Al and-85% for TFS and ETP substrates. The anticorrosion performance of the coatings was studied by electrochemical impedance spectroscopy at different immersion times (time intervals of 2-5 h during an overall stability test up to 170 h) in an aqueous solution of 1 wt% NaCl. The degree of polymerization and the physical properties of the coatings showed a strong dependence on the metal substrate used. In general, the best results were found for tomato pomace-based lacquers applied on aluminum, achieving higher mechanical strength (critical load of 1739 +/- 198 mN for Al, 1078 +/- 31 mN for ETP, and 852 +/- 206 mN for TFS), hydrophobicity (water contact angle-95 degrees for Al,-91 degrees for ETP, and-88 degrees for TFS), and improved anticorrosion performance (coating resistance of 0.7 M omega cm2 after 170 h of immersion for Al, 0.7 M omega cm2 after 70 h of immersion for TFS, and negligible coating resistance for ETP). In view of the technical innovation proposed in the present paper, the estimation of the environmental sustainability of the process has been considered relevant to fit the circular economy target. For this purpose, a life cycle analysis (LCA) was applied to the overall process, revealing multiple advantages for both the environment and human health.

February, 2023 | DOI: 10.1016/j.jclepro.2022.135836

Materiales de Diseño para la Energía y Medioambiente

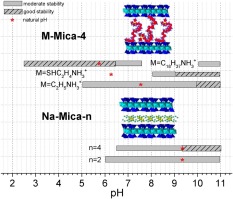

Improved stability of design clay minerals at high temperature: A comparison study with natural ones

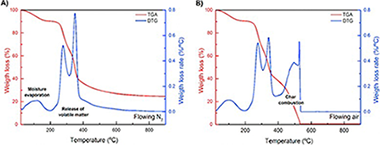

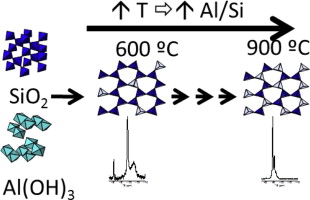

Osuna, FJ; Chaparro, JR; Pavon, E; Alba, MDCeramics International, 49 (2023) 5279-5291

Show abstract ▽

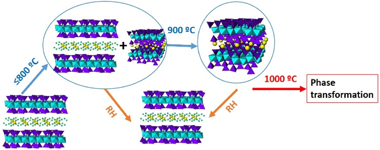

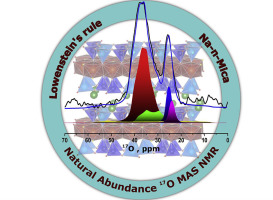

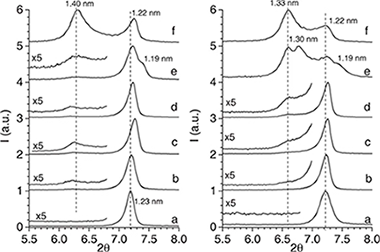

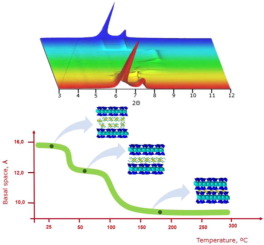

Clay minerals are ceramics materials that are involved in a wide range of economic uses. But, their structure and composition are modified by heating and, consequently, compromise their final applications. The actual tem-peratures at which changes occur vary greatly from one group to another group and even for different specimens within a given group. The aim of this research has been to evaluate the thermal behaviour of a set of design swelling micas, Na-Mica -n (Mn) and compare them with a set of natural smectites. All samples were heated in the range 200 degrees C to 1000 degrees C; afterwards, they were rehydrated thorough water suspension (0.4% wt). The results have shown that swelling micas have better property of hydration/dehydration than natural clay minerals and those with higher layer charge exhibited higher rehydration ability and dehydration temperature.

February, 2023 | DOI: 10.1016/j.ceramint.2022.10.046

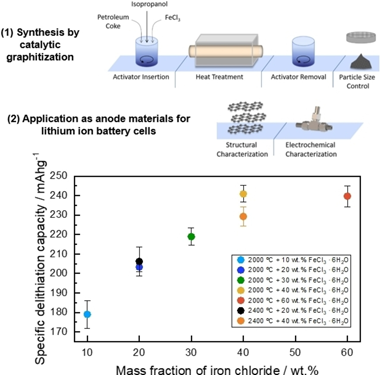

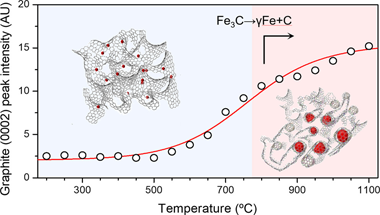

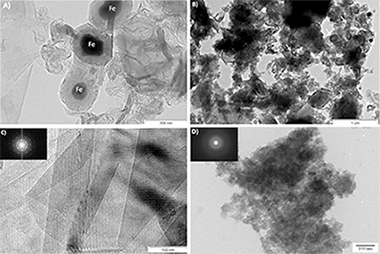

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

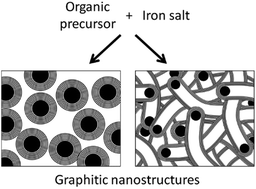

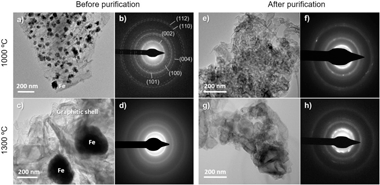

Revealing the Impact of Different Iron-Based Precursors on the ‘Catalytic’ Graphitization for Synthesis of Anode Materials for Lithium Ion Batteries