Scientific Papers in SCI

2018

2018

Nanotecnología en Superficies y Plasma

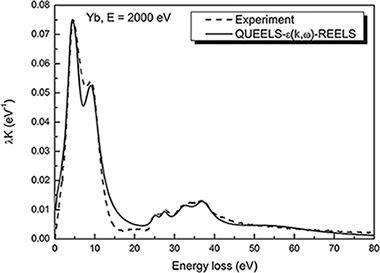

Quantitative analysis of Yb 4d photoelectron spectrum of metallic Yb

Pauly, N; Yubero, F; Tougaard, SSurface & Coatings Technology, 50 (2018) 1168-1173 DOI: 10.1002/sia.6402

Abstract

The measured Yb 4d(3/2) intensity is larger than the Yb 4d(5/2) in X-ray photoelectron (XPS) emission of metallic Yb, which is unexpected. The shape and intensity of photoelectron peaks are strongly affected by extrinsic excitations due to electron transport out of the surface (including bulk and surface effects) and to intrinsic excitations due to the sudden creation of the static core hole. To quantitatively extract from experimental XPS the primary excitation spectrum (ie, the initial excitation process) of the considered transition, these effects must be included within the theoretical description. The combined effect of both extrinsic and intrinsic excitations can be described by an effective energy-differential inelastic electron scattering cross section for XPS evaluated by a dielectric response model with the dielectric function as only input. Then, using this cross section, a direct evaluation of the primary excitation spectrum is performed by standard peak shape analysis for thick homogeneous samples. We use this approach in the present paper to determine the Yb 4d photoemission spectrum for metallic Yb. We show that the unexpected larger intensity of Yb 4d(3/2) compared to 4d(5/2) can be fully accounted for by our model and that the total spectrum consists of a sum of symmetric primary excitation peaks.

November, 2018 · DOI: 10.1002/sia.6402

Materiales de Diseño para la Energía y Medioambiente

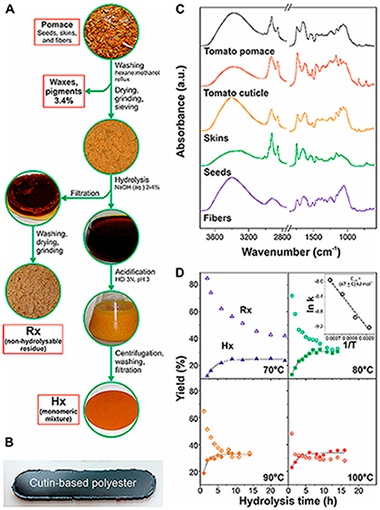

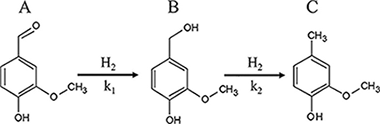

Valorization of Tomato Processing by-Products: Fatty Acid Extraction and Production of Bio-Based Materials

Benitez, JJ; Castillo, PM; del Rio, JC; Leon-Camacho, M; Dominguez, E; Heredia, A; Guzman-Puyol, S; Athanassiou, A; Heredia-Guerrero, JAMaterials, 11 (2018) art. 2211 DOI: 10.3390/ma11112211

Abstract

A method consisting of the alkaline hydrolysis of tomato pomace by-products has been optimized to obtain a mixture of unsaturated and polyhydroxylated fatty acids as well as a non-hydrolysable secondary residue. Reaction rates and the activation energy of the hydrolysis were calculated to reduce costs associated with chemicals and energy consumption. Lipid and non-hydrolysable fractions were chemically (infrared (IR) spectroscopy, gas chromatography/mass spectrometry (GC-MS)) and thermally (differential scanning calorimetry (DSC), thermogravimetric analysis (TGA)) characterized. In addition, the fatty acid mixture was used to produce cutin-based polyesters. Freestanding films were prepared by non-catalyzed melt-polycondensation and characterized by Attenuated Total Reflected-Fourier Transform Infrared (ATR-FTIR) spectroscopy, solid-state nuclear magnetic resonance (NMR), DSC, TGA, Water Contact Angles (WCA), and tensile tests. These bio-based polymers were hydrophobic, insoluble, infusible, and thermally stable, their physical properties being tunable by controlling the presence of unsaturated fatty acids and oxygen in the reaction. The participation of an oxidative crosslinking side reaction is proposed to be responsible for such modifications.

November, 2018 · DOI: 10.3390/ma11112211

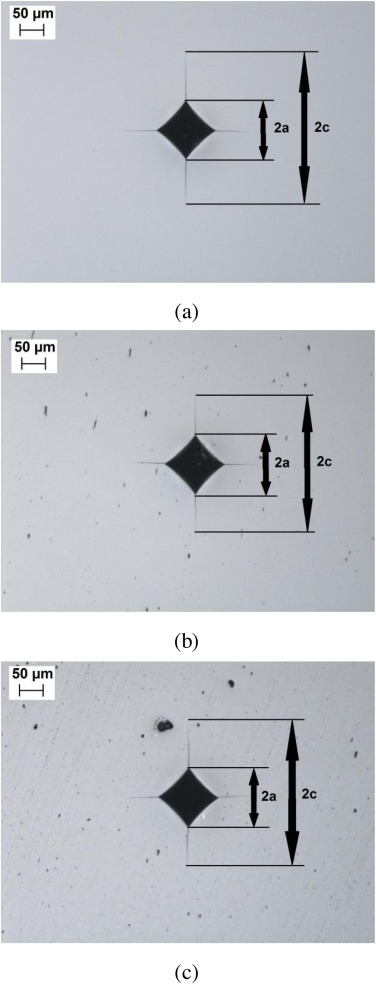

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

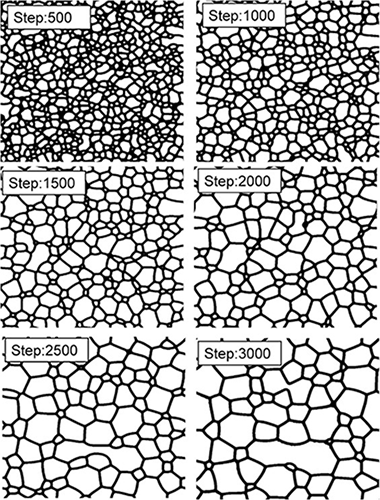

Exotic grain growth law in twinned boron carbide under electric fields

Moshtaghioun, BM; Gomez-Garcia, D; Rodriguez, ADJournal of the European Ceramic Society, 38 (2018) 4590-4596 DOI: 10.1016/j.jeurceramsoc.2018.06.029

Abstract

Grain growth is a ubiquitous phenomenon in all materials, and it affects both structural and functional properties. Despite its intrinsic importance, a full comprehension of grain growth from a fundamental point of view-i.e., from the nanoscale to the macroscale-is still a pending issue. In practical terms, our knowledge relies on the classical kinetic laws reported sixty years ago.

This paper reports the violation of such classical laws in boron carbide ceramics consolidated by spark plasma sintering. The conjunction of high temperature gradients with large compressive stress when a pulse electric current passes through the ceramic powders gives rise to an intense twinning-detwinning formation. These forming steps at the grain boundaries change the grain mobility drastically. Therefore, a new 'exotic' law for grain-growth kinetics is found and validated at different temperatures and dwell times.

November, 2018 · DOI: 10.1016/j.jeurceramsoc.2018.06.029

Nanotecnología en Superficies y Plasma - Materiales Nanoestructurados y Microestructura

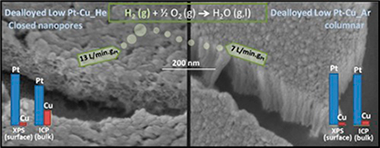

Nanoporous Pt-based catalysts prepared by chemical dealloying of magnetron-sputtered Pt-Cu thin films for the catalytic combustion of hydrogen

Giarratano, F; Arzac, GM; Godinho, V; Hufschmidt, D; de Haro, MCJ; Montes, O; Fernandez, AApplied Catalysis B-Environmental, 235 (2018) 168-176 DOI: 10.1016/j.apcatb.2018.04.064

Abstract

In this work, we prepared SiC-supported Pt-Cu thin films by magnetron sputtering for use as catalysts for the combustion of hydrogen under oxidizing conditions. We tested the catalysts as prepared and after chemical dealloying. A methodology is presented to fabricate catalytic thin films of a desired composition with tailored magnetron targets with lower Pt consumption. The deposition gas was changed to prepare columnar (Ar-deposited) and closed-porous (He-deposited) films to study the effect of the microstructure on the activity. The effect of composition was also studied for the columnar samples. The as-prepared Pt-Cu thin films showed significant activity only at temperatures higher than 100 °C. Dealloying permitted an increase in the activity to achieve near room-temperature activity. The dealloyed closed-porous He-deposited sample was the most active, being able to convert as much as 13.15 LH2·min−1 gPt−1 at 70 °C (Ea = 1 kJ mol−1). This sample was preferentially dealloyed on the surface, yielding an almost pure Pt shell (96% at. Pt) and a Cu-depleted interior (71% at. Pt). This compositional inhomogeneity enabled the sample to achieve enhanced activity compared to the Ar-deposited columnar sample (with similar initial composition, but uniformly dealloyed), probably due to the compressive surface lattice strain. The dealloyed closed-porous He-deposited sample was shown to be durable over five cycles.

November, 2018 · DOI: 10.1016/j.apcatb.2018.04.064

Materiales Ópticos Multifuncionales

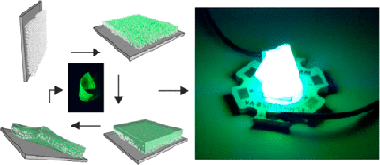

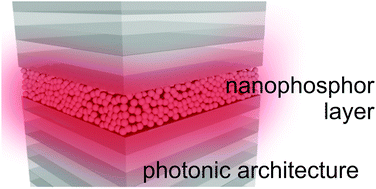

Highly Efficient and Environmentally Stable Flexible Color Converters Based on Confined CH3NH3PbBr3 Nanocrystals

Rubino, A; Anaya, M; Galisteo-Lopez, JF; Rojas, TC; Calvo, ME; Miguez, HACS Applied Materials & Interfaces, 10 (2018) 38334-38340 DOI: 10.1021/acsami.8b11706

Abstract

In this work, we demonstrate a synthetic route to attain methylammonium lead bromide (CH3NH3PbBr3) perovskite nanocrystals (nc-MAPbBr(3), 1.5 nm < size < 3 nm) and provide them with functionality as highly efficient flexible, transparent, environmentally stable, and adaptable color converting films. We use nanoparticle metal oxide (MOx) thin films as porous scaffolds of controlled nanopores size distribution to synthesize nc-MAPbBr(3) through the infiltration of perovskite liquid precursors. We find that the control over the reaction volume imposed by the nanoporous scaffold gives rise to a strict control of the nanocrystal size, which allows us to observe well-defined quantum confinement effects on the photo-emission, being the luminescence maximum tunable with precision between lambda = 530 nm (green) and lambda = 490 nm (blue). This hybrid nc-MAPbBr(3)/MOx structure presents high mechanical stability and permits subsequent infiltration with an elastomer to achieve a self-standing flexible film, which not only maintains the photo-emission efficiency of the nc-MAPbBr(3) unaltered but also prevents their environmental degradation. Applications as adaptable color-converting layers for light-emitting devices are envisaged and demonstrated.

November, 2018 · DOI: 10.1021/acsami.8b11706

Materiales de Diseño para la Energía y Medioambiente

Behavior of High-Strength Polypropylene Fiber-Reinforced Self-Compacting Concrete Exposed to High Temperatures

Rios, JD; Cifuentes, H; Leiva, C; Garcia, C; Alba, MDJournal of Materials in Civil Engineering, 30 (2018) 04018271 DOI: 10.1061/(ASCE)MT.1943-5533.0002491

Abstract

In this study we analyzed the use of high-performance structural concrete reinforced with polypropylene fibers in applications requiring long exposure times to high temperatures, such as thermal energy storage systems. We analyzed the behavior of the concrete at different temperatures (hot tests: 100 degrees C, 300 degrees C, 500 degrees C and 700 degrees C), cooled-down states (cold tests) and exposure times (6, 24, and 48h). We also experimentally determined the thermogravimetric analysis, fracture behavior, compressive strength, Young's modulus, and tensile strength of concrete. Subsequently, we performed a comprehensive analysis of the thermal and mechanical behavior of high-performance concrete under different thermal conditions. We applied longer exposure times to broaden the available results on the behavior of high-performance fiber-reinforced concrete when subjected to high temperatures. Results show that, once thermal and moisture equilibriums are reached, exposure time does not have any influence on mechanical properties. They also provide useful information about the influence of high temperatures on the different parameters of fiber-reinforced concrete and its application for thermal energy storage structures.

November, 2018 · DOI: 10.1061/(ASCE)MT.1943-5533.0002491

Nanotecnología en Superficies y Plasma

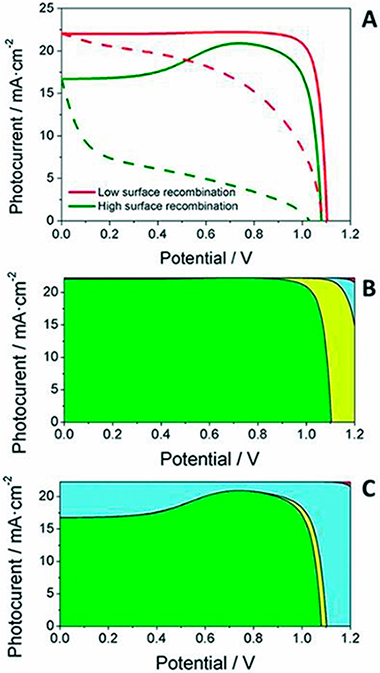

The Role of Surface Recombination on the Performance of Perovskite Solar Cells: Effect of Morphology and Crystalline Phase of TiO2 Contact

Idigoras, J; Contreras-Bernal, L; Cave, JM; Courtier, NE; Barranco, A; Borras, A; Sanchez-Valencia, JR; Anta, JA; Walker, ABAdvanced Materials Interfaces, 5 (2018) art. 1801076 DOI: 10.1002/admi.201801076

Abstract

Herein, the preparation of 1D TiO2 nanocolumnar films grown by plasma-enhanced chemical vapor deposition is reported as the electron selective layer (ESL) for perovskite solar devices. The impact of the ESL architecture (1D and 3D morphologies) and the nanocrystalline phase (anatase and amorphous) is analyzed. For anatase structures, similar power conversion efficiencies are achieved using an ESL either the 1D nanocolumns or the classical 3D nanoparticle film. However, lower power conversion efficiencies and different optoelectronic properties are found for perovskite devices based on amorphous 1D films. The use of amorphous TiO2 as electron selective contact produces a bump in the reverse scan of the current-voltage curve as well as an additional electronic signal, detected by impedance spectroscopy measurements. The dependence of this additional signal on the optical excitation wavelength used in the IS experiments suggests that it stems from an interfacial process. Calculations using a drift-diffusion model which explicitly considers the selective contacts reproduces qualitatively the main features observed experimentally. These results demonstrate that for a solar cell in which the contact is working properly the open-circuit photovoltage is mainly determined by bulk recombination, whereas the introduction of a "bad contact" shifts the balance to surface recombination.

November, 2018 · DOI: 10.1002/admi.201801076

Nanotecnología en Superficies y Plasma

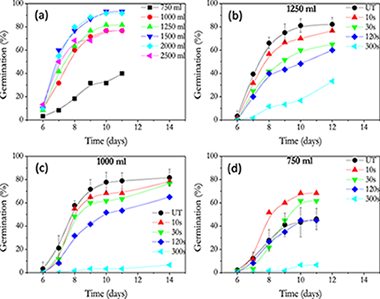

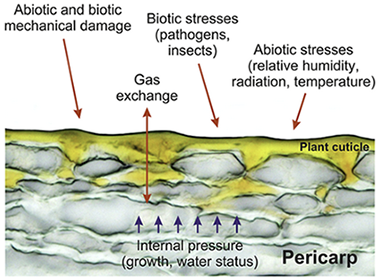

Influence of irrigation conditions in the germination of plasma treated Nasturtium seeds

Molina, R; Lopez-Santos, C; Gomez-Ramirez, A; Vilchez, A; Espinos, JP; Gonzalez-Elipe, ARScientific Reports, 8 (2018) art. 16442 DOI: 10.1038/s41598-018-34801-0

Abstract

Plasma treatments had emerged as a useful technique to improve seed germination. In this work we investigate the influence of different irrigation conditions and plasma treatments on the germination of nasturtium seeds. During plasma treatment, seeds experience a progressive weight loss as a function of treatment time that has been associated to water release, a process that is more pronounced after longer plasma treatment times. Seeds treated for short times (<30 s) are able to germinate more efficiently than untreated specimen under hydric stress (drought conditions), while plasma treatments for longer times (up to 300 s) impaired germination independently on irrigation conditions. Characterization analysis of plasma treated seeds by FTIR-ATR, SEM/EDX and XPS showed that plasma treatment affected the chemical state of pericarp while, simultaneously, induced a considerable increase in the seeds water uptake capacity. The decrease in germination efficiency found after plasma treatment for long times, or for short times under optimum irrigation conditions, has been attributed to that the excess of water accumulated in the pericarp hampers the diffusion up to the embryo of other agents like oxygen which are deemed essential for germination.

November, 2018 · DOI: 10.1038/s41598-018-34801-0

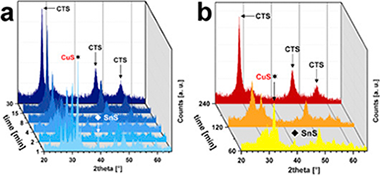

Reactividad de Sólidos

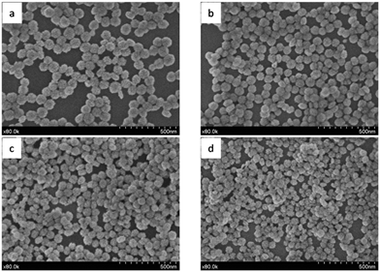

Scalable synthesis of potential solar cell absorber Cu2SnS3 (CTS) from nanoprecursors

Hegedus, M; Balaz, M; Tesinsky, M; Sayagues, MJ; Siffalovic, P; Krulakova, M; Kanuchova, M; Briancin, J; Fabian, M; Balaz, PJournal of Alloys and Compounds, 768 (2018) 1006-1015 DOI: 10.1016/j.jallcom.2018.07.284

Abstract

The present paper demonstrates an easy and scalable mechanochemical synthesis of ternary sulfide Cu2SnS3 (CTS) as a promising solar cell absorber. For the synthesis, pre-milled nanoparticles of CuS and SnS were used. The pure CTS phase was readily obtained after 60 min of milling in a laboratory planetary ball mill and 240 min in an industrial eccentric vibration industrial mill, respectively. The reaction progress of laboratory scale synthesis was studied by the quantitative Rietveld analysis. The reaction speed reaches its maximum at 4.6 min and the reaction is completed at approximately 60 min, according to the fitted data. The products of the syntheses were further characterized by X-ray powder diffractometry, Raman spectroscopy, scanning electron microscopy, X-ray photoelectron spectroscopy and UV-Vis spectroscopy. The results revealed formation of near-stoichiometric CTS nanoparticles with tetragonal I-42m symmetry. An average crystallites size of approximately 10-15 nm was determined for CTS phase. The SEM images support quintessential polydisperse character of the powders obtained by ball-milling approach. The materials seem to be suitable for photovoltaic applications with the band-gap energies of approximately 1.16-1.19 eV.

November, 2018 · DOI: 10.1016/j.jallcom.2018.07.284

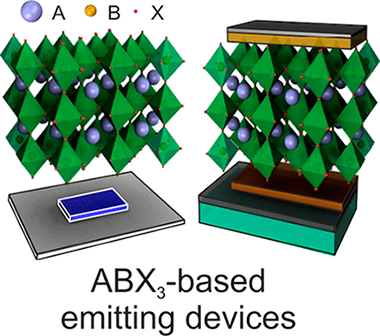

Materiales Ópticos Multifuncionales

High voltage vacuum-deposited CH3NH3PbI3–CH3NH3PbI3 tandem solar cells

Avila, J; Momblona, C; Boix, P; Sessolo, M; Anaya, M; Lozano, G; Vandewal, K; Miguez, H; Bolink, HJEnergy & Environmental Science, 11 (2018) 3292-3297 DOI: 10.1039/c8ee01936c

Abstract

The recent success of perovskite solar cells is based on two solid pillars: the rapid progress of their power conversion efficiency and their flexibility in terms of optoelectrical properties and processing methods. That versatility makes these devices ideal candidates for multi-junction photovoltaics. We report an optically optimized double junction CH3NH3PbI3-CH3NH3PbI3 tandem solar cell where the matched short-circuit current is maximized while parasitic absorption is minimized. The use of an additive vacuum-deposition protocol allows us to reproduce calculated stack designs, which comprise several charge selective materials that ensure appropriate band alignment and charge recombination. This rationalized configuration yields an unprecedented open circuit voltage of 2.30 V. Furthermore, this tandem solar cell features efficiencies larger than 18%, higher than those of the individual sub-cells. Low photo-current values allow reducing the losses associated to the series resistance of transparent contacts, which opens the door to the realization of efficient large area modules.

November, 2018 · DOI: 10.1039/c8ee01936c

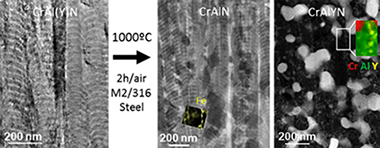

Tribología y Protección de Superficies

High-temperature oxidation of CrAlYN coatings: Implications of the presence of Y and type of steel

Rojas, TC; Dominguez-Meister, S; Brizuela, M; Sanchez-Lopez, JCSurface & Coatings Technology, 354 (2018) 203-2013 DOI: 10.1016/j.surfcoat.2018.09.020

Abstract

Nanolayered CrAIN and CrAIYN/CrAIN (average contents of Al approximate to 25 at.% and Y approximate to 1.6 at. %) coatings are deposited on M2 and 316 steel substrates and heated to 1000 degrees C in air for 2 h to study their oxidation mechanism, the thermal stability and the reactive element (RE) effect of yttrium. CrAIN on M2 develops a Cr2O3/Al2O3 passivation layer that preserves in high degree the fcc-CrAIN structure however iron ions leave the substrate and travel to the surface along the column boundaries. The CrAIYN/CrAIN coatings deposited on steels are not stable at 1000 degrees C, and the initial fcc-CrAIN phase is partially transformed to hcp-Al(O)N and Cr-Fe phases (M2) and Cr2N and Al2O3 (316). The addition of Y changes the predominant scale growth direction. Inward oxygen diffusion becomes dominant but a reduction of the oxide scale thickness as compared to CrAIN is not observed. The advanced microstructural analysis made by transmission electron microscopy combined with electron energy loss spectroscopy determined that yttrium migrates mainly to the oxide scale (forming mixed oxides with substrate elements - V and Mo, either as dispersed particles or segregated at the grain boundaries) in M2, and to the oxide interface and column boundaries (forming Al-Y oxides and YN, respectively) in 316 steel. The benefits of addition of Y in improving the oxidation resistance are discussed comparatively with literature data. The RE effect of yttrium is thus observed to be dependent on the substrate, film architecture and composition.

October, 2018 · DOI: 10.1016/j.surfcoat.2018.09.020

Reactividad de Sólidos

Study of the thermal decomposition of historical metal threads

Perez-Rodriguez, JL; Perez-Maqueda, R; Franquelo, ML; Duran, AJournal of Thermal Analysis and Calorimetry, 134 (2018) 15-22 DOI: 10.1007/s10973-017-6924-x

Abstract

In this work, it is reported that thermal analysis techniques such as differential thermal analysis and thermogravimetric analysis are very useful for evaluating metals threads and fibres used in the manufacture of historical artifacts. Thermal analysis has been used to characterize the silk, cotton and linen employed as supports and the copper, silver and aluminium as the metallic components in the studied threads. Other organic compounds, mainly added for the conservation of the threads, have also been characterized.

October, 2018 · DOI: 10.1007/s10973-017-6924-x

Fotocatálisis Heterogénea: Aplicaciones

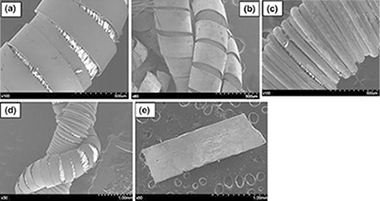

Photocatalytic H2 production from glycerol aqueous solutions over fluorinated Pt-TiO2 with high {001} facet exposure

V. Vaiano; M.A. Lara; G. Iervolino; M. Matarangolo; J.A. Navío; M.C. HidalgoJournal of Photochemistry and Photobiology A-Chemistry, 365 (2018) 52-59 DOI: 10.1016/j.jphotochem.2018.07.032

Abstract

An optimized fluorinated TiO2 catalyst with high {001} facet exposure loaded with platinum (TiO2-PtFAC) was tested in the photocatalytic hydrogen production from glycerol solution under UV light irradiation. The samples were synthesized by direct hydrothermal treatment starting from two different types of precursors that are titanium tetraisopropoxide (I) or titanium butoxide (B), while platinisation was performed by photodeposition method. The obtained catalysts were characterised by different techniques (XRD, FESEM, TEM, BET, UV–vis DRS, XRF and XPS) and the results evidenced that anatase is the only crystalline phase present in all TiO2 samples. The morphology of the samples was seen as rectangular platelets particles where Pt particles were was observed all over the surface. The presence of Pt and F in the platinised samples was also confirmed by XRF and XPS analysis. The photocatalytic results have shown that the presence of Pt on TiO2{001}facet surface remarkably enhanced the hydrogen production from aqueous solution at 5 wt % of glycerol. Comparing the results obtained from the photocatalysts prepared by the two different precursors, it was found that the best performances in terms of H2 production was achieved with TiO2-PtFAC(I) (about 13 mmol L−1 after 4 h of irradiation time), while the H2 production was lower for TiO2-PtFAC(B) (about 9 mmol L−1 after 4 h of irradiation time). The effect of the operating conditions using TiO2-PtFAC(I) evidenced that the highest H2 production was obtained with a photocatalyst dosage equal to 1.5 g L−1, initial glycerol concentration at 5 wt% and a pH value equal to 7. Finally, a photocatalytic test was also performed on glycerol solution prepared with a real water matrix. Despite the presence of ions scavengers (chlorides and carbonates) in solution, TiO2-PtFAC(I) was able to reach a photocatalytic H2production of about 6 mmol L−1 after 4 h of UV light irradiation.

October, 2018 · DOI: 10.1016/j.jphotochem.2018.07.032

Reactividad de Sólidos

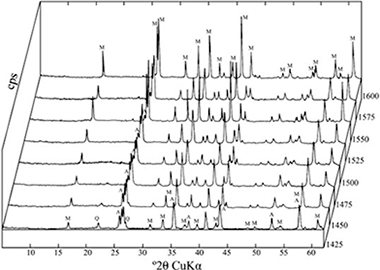

Isosymmetric structural phase transition of the orthorhombic lanthanum gallate structure as a function of temperature determined by Rietveld analysis

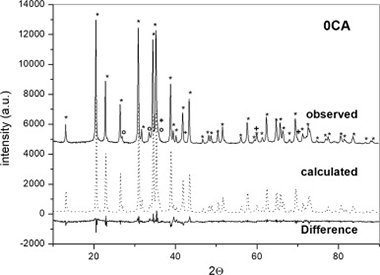

Tang, Y. Q.; Lopez-Cartes, C.; Aviles, M. A.; Cordoba, J. M.CRYSTENGCOMM, 20 (2018) 5562-5569 DOI: 10.1039/c8ce00726h

Abstract

High energy planetary ball milling has been used to synthesize pseudo-cubic highly-pure LaGaO3 in one hour from its oxide components in an air atmosphere. Calcination at different temperatures led to the crystallization of lanthanum gallate in an orthorhombic structure with its local lanthanum coordination number environment changing from 12 to 7 when the temperature was increased. This change was attributed to the thermal expansion of the Ga-O bonds that varied non-monotonically inducing GaO6 tilting. Rietveld analysis, Raman spectroscopy, and transmission electron microscopy were used to elucidate the LaGaO3 structures at different temperatures.

October, 2018 · DOI: 10.1039/c8ce00726h

Reactividad de Sólidos

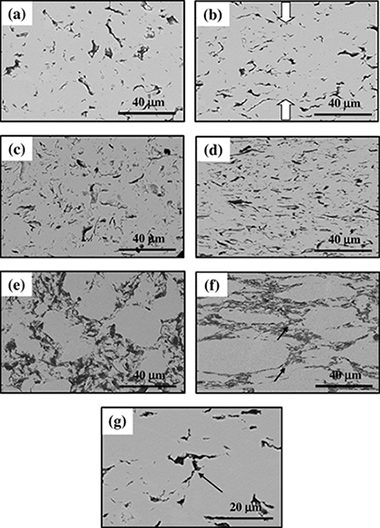

Optimizing the homogenization technique for graphene nanoplatelet/yttria tetragonal zirconia composites: Influence on the microstructure and the electrical conductivity

Lopez-Pernia, C; Munoz-Ferreiro, C; Gonzalez-Orellana, C; Morales-Rodriguez, A; Gallardo-Lopez, A; Poyato, RJournal of Alloys and Compounds, 767 (2018) 994-1002 DOI: 10.1016/j.jallcom.2018.07.199

Abstract

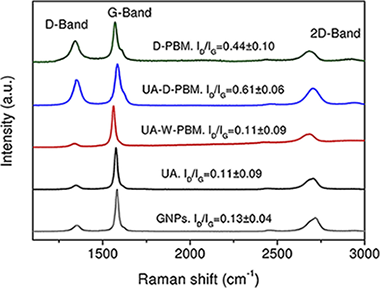

3 mol% yttria tetragonal zirconia polycrystalline (3YTZP) ceramic composite powders with 10 vol% nominal content of graphene nanoplatelets (GNPs) were prepared using four different homogenization routines: dispersion of the powder mixture by ultrasonication in isopropyl alcohol, homogenization in a high-energy planetary ball mill in wet or dry conditions after ultrasonication, and milling of the powders in a high-energy planetary ball mill in dry conditions. A significant effect of the homogenization routine on the powders particle size distribution was revealed by laser granulometry and Raman spectroscopy. Highly densified composites were obtained after spark plasma sintering (SPS) and remarkable differences on the GNP size, shape and distribution throughout the ceramic matrix and also in the electrical conductivity were observed in the four different composites. The composite with the best performance in terms of electrical conductivity was the one prepared after planetary ball milling of the powders in dry conditions as a consequence of the reduced dimensions of the GNPs and their excellent distribution throughout the ceramic matrix.

October, 2018 · DOI: 10.1016/j.jallcom.2018.07.199

Reactividad de Sólidos

The role of carbon nanotubes on the stability of tetragonal zirconia polycrystals

Morales-Rodriguez, A; Poyato, R; Gutierrez-Mora, F; Munoz, A; Gallardo-Lopez, ACeramics International, 44 (2018) 17716-17723 DOI: 10.1016/j.ceramint.2018.06.238

Abstract

The effect of single walled carbon nanotubes (SWNT) at zirconia grain boundaries on the stability of a tetragonal zirconia polycrystalline matrix has been explored in as-sintered composites and after low temperature hydro thermal degradation (LTD) experiments. For this purpose, highly-dense 3 mol% Y2O3-doped tetragonal zirconia polycrystalline (3YTZP) ceramics and SWNT/3YTZP composites were prepared by spark plasma sintering (SPS). Quantitative X-ray diffraction analysis and microstructural observations point out that an increasing amount of well-dispersed SWNT bundles surrounding zirconia grains decreases the metastable tetragonal phase retention in the ceramic matrix after sintering. In contrast, the tetragonal ceramic grains in composites with SWNTs are less sensitive to the presence of water, i.e. to undergo a martensitic transformation under LTD conditions, than monolithic 3YTZP ceramics. The SWNT incorporation diminishes micro-cracking due to tetragonal to monoclinic ZrO2 phase transformation in the composites.

October, 2018 · DOI: 10.1016/j.ceramint.2018.06.238

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

Grain-boundary diffusion coefficient in alpha-Al2O3 from spark plasma sintering tests: Evidence of collective motion of charge disconnections

Tamura, Y; Zapata-Solvas, E; Moshtaghioun, BM; Gomez-Garcia, D; Dominguez-Rodriguez, ACeramics International, 44 (2018) 19044-19048 DOI: 10.1016/j.ceramint.2018.07.073

Abstract

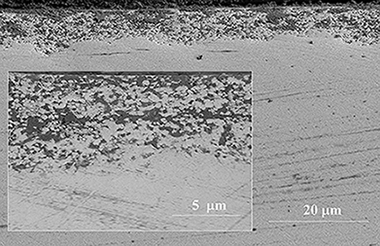

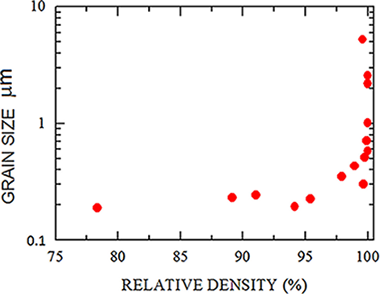

The sintering of fine-grained a-alumina by spark plasma sintering (SPS) was performed to study grain growth under SPS conditions. Grain growth is found to be extensive at relative densities above 95%. A grain growth versus dwell time analysis during SPS allows for the determination of the grain-boundary diffusion coefficient. This study shows that the remarkable enhancement of grain-boundary diffusion derived from a previous analysis could be a consequence of the presence of the recently discovered "disconnections" at the grain boundaries of alpha-alumina. Their presence, together with their electric charge and the external electric field at the boundaries, are the key ingredients for a violation of the typical grain growth kinetic law. When they are introduced appropriately, an updated value of the grain-boundary diffusion coefficient is achieved. A comparison with other values reported previously in the literature through other techniques and a critical analysis are also carried out.

October, 2018 · DOI: 10.1016/j.ceramint.2018.07.073

Materiales Avanzados

Biomass fly ash and aluminium industry slags-based geopolymers

Perez-Villarejo, L; Bonet-Martinez, E; Eliche-Quesada, D; Sanchez-Soto, PJ; Rincon-Lopez, JM; Castro-Galiano, EMaterials Letters, 229 (2018) 6-12 DOI: 10.1016/j.matlet.2018.06.100

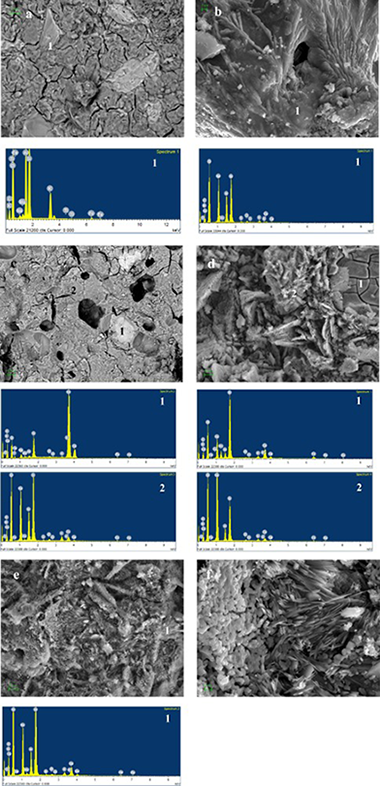

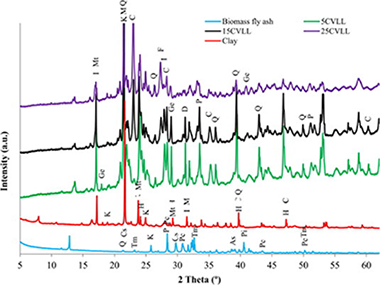

Abstract

Geopolymers are a new class of non-Portland cements produced using an alumino-silicate material and an activating solution, which is mainly composed of sodium or potassium and waterglass to be subsequently cured at relatively low temperatures. Those can be formulated by adding natural minerals, waste and/or industrial by-products. The study investigates the microstructural properties of geopolymers synthesized from metakaolin (MK) and the admixture of fly ash (FBA) and aluminium industry slags (AIS) at different ages of curing. Five different geopolymer compositions were prepared and characterized by XRD, ATR-FTIR and SEM/EDS. The study revealed that geopolymeric gels are identified, which show mainly glassy microstructures, in agreement with the X-ray amorphous diffraction patterns, broad FTIR features and confirmed by SEM/EDS, with promising results prior to an industrial scale.

October, 2018 · DOI: 10.1016/j.matlet.2018.06.100

Reactividad de Sólidos

Mesoporous Silica by Solution-Combustion Synthesis Followed by Etching

Salehtash, F; Jalaly, M; Motejadded Emrooz, HB; Gotor, FJ; Sayagués, MJInternational Journal of Self-Propagating High-Temperature Synthesis, 27 (2018) 221–227 DOI: 10.3103/S1061386218040064

Abstract

Mesoporous silica was synthesized through the solution-combustion process followed by etching with aqueous solution of sodium dodecyl sulfate (SDS). Combustion products were characterized by XRD, FTIR, SEM, TEM, HRTEM, and BET analysis. After etching, the specific surface, mean pore size, and volume of porous space in silica increased up to 390 m(2)/g, 15 nm, and 1.6 cm(3)/g, respectively. The synthesized mesoporous silica exhibited good performance in the tests on elimination of methylene blue from aqueous solution.

October, 2018 · DOI: 10.3103/S1061386218040064

Materiales Avanzados

Manufacture of sustainable clay ceramic composite with composition SiO2-Al2O3-CaO-K2O materials valuing biomass ash from olive pomace

Bonet-Martinez, E; Perez-Villarejo, L; Eliche-Quesada, D; Sanchez-Soto, PJ; Carrasco-Hurtado, B; Castro-Galiano, EMaterials Letters, 229 (2018) 21-25 DOI: 10.1016/j.matlet.2018.06.105

Abstract

Fly ash is a biomass combustion by-product produced by dragging ash from the base of the furnace. Disposing of ash is a growing economic and environmental burden. Based on physical and chemical properties, fly ash could be used in the manufacture of construction materials. This paper investigates the influence of biomass fly ash from olive pomace as additive to manufacture of clay ceramic composite materials. Fired clay brick at 950 degrees C were prepared containing between 0 and 25 wt% fly ash. Final products are studied by water absorption, bulk density, loss of ignition, linear shrinkage, compressive strength and physisorption N-2. The results reveal that the porosity of the materials increases with the level of fly ash replacement (10% up to 25 wt%) resulting in to increased water absorption and decreased compressive strength. Fired clay brick developed in this study can be used for construction materials based on criteria of the current regulations.

October, 2018 · DOI: 10.1016/j.matlet.2018.06.105

Spanish and Portuguese Gilding Threads: Characterization Using Microscopic Techniques

Perez-Rodriguez, JL; Albardonedo, A; Robador, MD; Duran, AMicroscopy and Microanalysis, 24 (2018) 574-590 DOI: 10.1017/S1431927618015167

Abstract

Gilding threads collected from Spanish and Portuguese palaces and from the embroideries and adornments of sculptures of the Virgin and Christ that form part of Sevillian Holy Week were analyzed and compared (20 artifacts were evaluated). The study covered a broad time period with examples from the 13th to 14th centuries, 18th to 20th centuries, and also including modern embroideries. A combination of scanning electron microscopy and energy-dispersive X-ray spectroscopy was used. The knowledge of the layered structures of the threads has provided very valuable information regarding the manufacturing techniques. The different metal threads found in the embroidery studied consisted of gold, silver, copper, and alloys of these metals and aluminium. The fabrication procedures often differed in the different workshops and changed with time. In the modern embroideries, a decrease of precious metal concentration was detected. The threads were wound around a core of silk threads.

October, 2018 · DOI: 10.1017/S1431927618015167

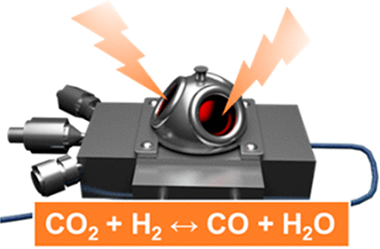

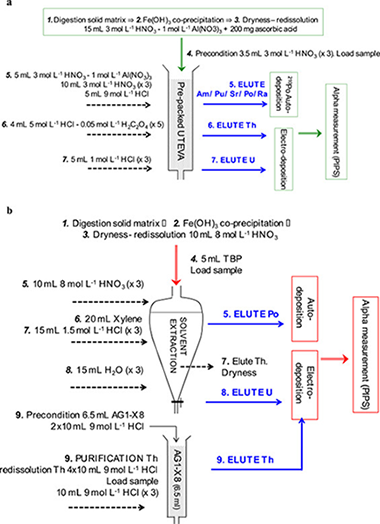

Química de Superficies y Catálisis - Reactividad de Sólidos

A direct in situ observation of water-enhanced proton conductivity of Eu-doped ZrO2: Effect on WGS reaction

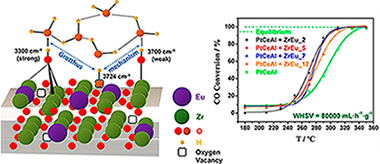

Garcia-Moncada, N; Bobadilla, LF; Poyato, R; Lopez-Cartes, C; Romero-Sarria, F; Centeno, MA; Odriozola, JAApplied Catalysis B-Environmental, 231 (2018) 343-356 DOI: 10.1016/j.apcatb.2018.03.001

Abstract

Eu-doped ZrO2 solid solutions have been synthesized in order to prepare proton conductors as water-enhancer additives for the WGS reaction. Elemental characterization has been carried out revealing homogeneous dopant distribution resulting in fluorite-type solid solutions for Eu2O3 contents up to similar to 9 mol.%. Representative samples of the Eu-doped ZrO2 series have been analysed by Impedance Spectroscopy (IS) in inert, oxygen and wet conditions. The solid solution with 5 mol.% of Eu2O3 has presented the highest conductivity values for all tested conditions indicating an optimal amount of dopant. Moreover, the presence of vapour pressure results in an increment of the conductivity at temperatures lower than 300 degrees C, meanwhile at higher temperatures the conductivity is the same than that in inert conditions. To elucidate these results, in situ DRIFTS studies were carried out. These experiments evidenced the existence of water dissociation at oxygen vacancies (band at 3724 cm(-1)) as well as the presence of physisorbed water at temperatures up to similar to 300 degrees C where the band at 5248 cm(-1) characteristic of these species disappeared. These results points to a layer model where the physisorbed water interacts with surface hydroxyls generated by dissociated water that improves the proton conductivity through Grotthuss' mechanism in the RT-300 degrees C temperature range. These samples were successfully tested in WGS reaction as additive to a typical Pt-based catalyst. The presence of the mixed oxide reveals an increase of the catalyst' activity assisted by the proton conductor, since improves the water activation step.

September, 2018 · DOI: 10.1016/j.apcatb.2018.03.001

Materiales de Diseño para la Energía y Medioambiente

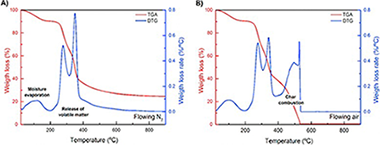

Performance improvement in olive stone's combustion from a previous carbonization transformation

Gomez-Martin, A; Chacartegui, R; Ramirez-Rico, J; Martinez-Fernandez, JFuel, 228 (2018) 254-262 DOI: 10.1016/j.fuel.2018.04.127

Abstract

Under the framework of circular economy, agricultural wastes are an interesting carbon-based feedstock for thermal energy and power generation. Their use could extend the availability of biomass-based fuel and, at the same time, would reduce negative environmental effects. However, depending on the residues' characteristics, their direct combustion in boilers presents some challenges which could be overcome with a carbonization pretreatment. In this paper, the main mechanisms of thermochemical transformation of an abundant agricultural waste, olive stone, into biochar products via slow carbonization are analyzed, with emphasis on the effect of peak carbonization temperature. Thermogravimetric and differential scanning calorimetry analysis are used to evaluate the performance of the resulting biochars compared to raw olive stone in combustion processes and to assess the correlation between the peak carbonization temperature and compositional and fuel properties. Results show that with a prior treatment up to an optimum temperature of 800 degrees C the energy density is increased up to three times compared to the raw material. These findings suggest that carbonization of olive stones reduces the barriers to their direct use in current biomass boiler technology.

September, 2018 · DOI: 10.1016/j.fuel.2018.04.127

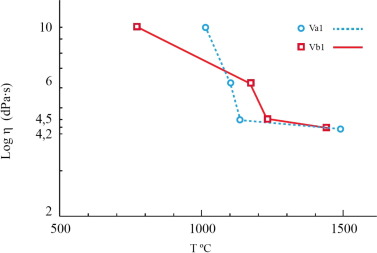

Reactividad de Sólidos

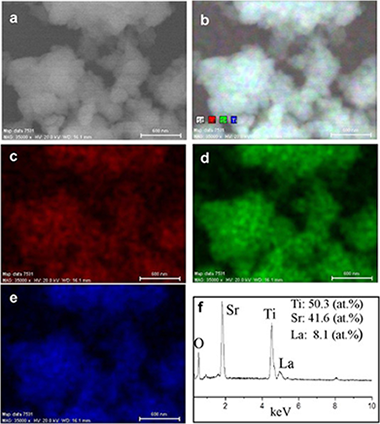

Mechanosynthesis of Sr1-xLaxTiO3 anodes for SOFCs: Structure and electrical conductivity

Sayagues, MJ; Gotor, J; Pueyo, M; Poyato, R; Garcia-Garcia, FJJournal of Alloys and Compounds, 763 (2018) 679-686 DOI: 10.1016/j.jallcom.2018.05.243

Abstract

Sr1-xLaxTiO3 (SLT; 0 <= x <= 0.5) powder samples were synthesised at room temperature by a mechanochemical method from SrO, La2O3 and TiO2 mixtures in 90 min. The obtained SLT samples as potential anode materials in solid oxide fuel cells (SOFCs) were investigated. The microstructure, electrical conductivity and chemical compatibility with yttria-stabilised zirconia (YSZ) were studied. The powder samples had a nanometric character after milling. After a subsequently heating at 900 degrees C, the particle size slightly increased, but still remained nanometric. At this high temperature, a good chemical compatibility with YSZ was found. The x = 0.2 sample gave the best electrical conductivity values, i.e. 0.23 W cm(-2). These features make such as-obtained samples good candidates to be used as anodes in SOFCs.

September, 2018 · DOI: 10.1016/j.jallcom.2018.05.243

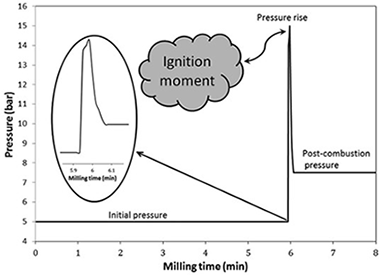

Reactividad de Sólidos

Nanostructured vanadium carbonitride prepared by combustion synthesis during mechanical milling

Jalaly, M; Gotor, FJ; Sayagues, MJJournal of Alloys and Compounds, 763 (2018) 18-24 DOI: 10.1016/j.jallcom.2018.05.352

Abstract

Vanadium carbonitride (VCN) nanoparticles were synthesized by a mechanically induced magnesiothermic combustion in a Mg/V2O5/C3H6N6 system. Initial materials ignited after a short milling time of 6 min. Various characterizations such as X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), energy-dispersive X-ray spectroscopy (EDX), high-resolution transmission electron microscopy (HRTEM) and elemental mapping confirmed that the product of the combustion was a mixed carbonitride. In this process, magnesium reduces vanadium oxide to generate elemental V and a great amount of heat. Melamine decomposes due to the temperature rise, and its decomposed species form the carbonitride compound. The chemical composition of the synthesized product was estimated to be VC0.26N0.36.

September, 2018 · DOI: 10.1016/j.jallcom.2018.05.352

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

Graphene or carbon nanofiber-reinforced zirconia composites: Are they really worthwhile for structural applications?

Cano-Crespo, R; Moshtaghioun, BM; Gomez-Garcia, D; Moreno, R; Dominguez-Rodriguez, AJournal of the European Ceramic Society, 38 (2018) 3994-4002 DOI: 10.1016/j.jeurceramsoc.2018.04.045

Abstract

The use of allotropic phases of carbon (i.e. nanotubes, graphene or carbon nanofibers) as second phases to design ceramic composites is a hot topic at present. Researchers try to provide a remarkable improvement of the parent ceramic assuming that some of the outstanding mechanical properties of these phases migrate to the resultant composite. This reasonable idea has been questioned severely in the case of nanotubes addition but there is not any analysis for the other two phases cited previously. To elucidate this question, zirconia was selected as a model ceramic. This paper reports the mechanical properties of zirconia composites reinforced either with graphene or carbon nanofibers, with special emphasis on the high-temperature plasticity.

September, 2018 · DOI: 10.1016/j.jeurceramsoc.2018.04.045

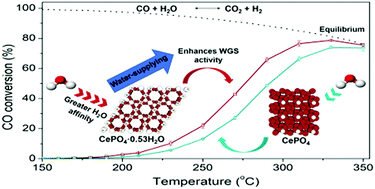

Química de Superficies y Catálisis

Pt/CePO4 catalysts for the WGS reaction: influence of the water-supplier role of the support on the catalytic performance

Navarro-Jaen, S; Centeno, MA; Laguna, OH; Odriozola, JAJournal of Materials Chemistry A, 6 (2018) 17001-17010 DOI: 10.1039/c8ta04603d

Abstract

For Pt catalysts which have demonstrated great activity for the WGS reaction, the activation of water is described as the rate-limiting step. Such limitation could be overcome through the design of supports able to supply water. In this study, the hexagonal and monoclinic phases of CePO4 have been evaluated as supports for Pt WGS catalysts. The hexagonal structure presents channels containing water, absent in the monoclinic structure. The presence of these channels in the hexagonal phase increases the interaction with the water molecules, leading to an enhancement of the WGS catalytic performance. DRIFTS results showed that dissociation of water does not occur on these supports, while calculated apparent activation energies present values similar to those reported in the literature for the dissociation of water in Pt (111). These results suggest that cerium phosphates act as water suppliers, increasing the number of available species to be dissociated on the Pt surface.

September, 2018 · DOI: 10.1039/c8ta04603d

Materiales de Diseño para la Energía y Medioambiente

A comprehensive and in-depth analysis of the synthesis of advanced adsorbent materials

Osuna, FJ; Cota, A; Pavon, E; Alba, MDJournal of Cleaner Production, 194 (2018) 665-672 DOI: 10.1016/j.jclepro.2018.05.179

Abstract

Na-Mica-4, a synthetic fluorophlogopite, is an attractive adsorbent. However, the synthesis at large scale demands an economically prized, feasible scalable and sustainable synthesis method, which requires a deep knowledge of the influence of each synthesis step. A set of Na-Mica-4 were synthesized by methods that had one synthesis parameter as variable. The purity, crystallinity and heteroatoms distribution were analysed thorough X-ray diffraction and nuclear magnetic resonance. The results shed a light on the main factors for the design of the final product and indicated that an environmental friendship synthesis could be possible.

September, 2018 · DOI: 10.1016/j.jclepro.2018.05.179

Materiales Ópticos Multifuncionales

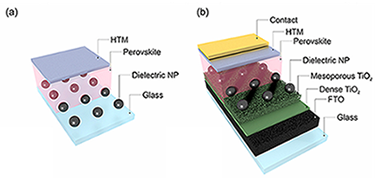

Absorption enhancement in methylammonium lead iodide perovskite solar cells with embedded arrays of dielectric particles

Jimenez-Solano, A; Carretero-Palacios, S; Miguez, HOptics Express, 26 (2018) A865-A878 DOI: 10.1364/OE.26.00A865

Abstract

In the field of hybrid organic-inorganic perovskite based photovoltaics, there is a growing interest in the exploration of novel and smarter ways to improve the cells light harvesting efficiency at targeted wavelength ranges within the minimum volume possible, as well as in the development of colored and/or semitransparent devices that could pave the way both to their architectonic integration and to their use in the flowering field of tandem solar cells. The work herein presented targets these different goals by means of the theoretical optimization of the optical design of standard opaque and semitransparent perovskite solar cells. In order to do so, we focus on the effect of harmless, compatible and commercially available dielectric inclusions within the absorbing material, methylammonium lead iodide (MAPI). Following a gradual and systematic process of analysis, we are capable of identifying the appearance of collective and hybrid (both localized and ex tended) photonic resonances which allow to significantly improve light harvesting and thus the overall efficiency of the standard device by above 10% with respect to the reference value while keeping the semiconductor film thickness to a minimum. We believe our results will be particularly relevant in the promising field of perovskite solar cell based tandem photovoltaic devices, which has posed new challenges to the solar energy community in order to maximize the performance of semitransparent cells, but also for applications focusing on architectonic integration.

September, 2018 · DOI: 10.1364/OE.26.00A865

Nanotecnología en Superficies y Plasma

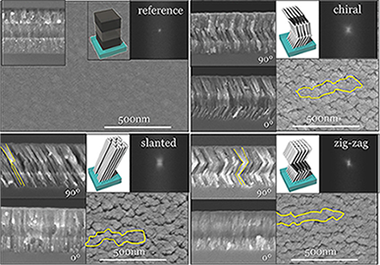

Nanostructural Analysis of Porous Oblique Angle Deposited (OAD) Multilayer Systems by Grazing-Incidence Small-Angle X-Ray Scattering

Oliva-Ramirez, M; Lopez-Santos, C; Yubero, F; Gonzalez-Elipe, ARAdvanced Optical Materials, 5 (2018) 1800530 DOI: 10.1002/admi.201800530

Abstract

This work reports a thorough characterization analysis of various porous thin film multilayers by means of grazing-incidence small-angle X-ray scattering (GISAXS). Alternated TiO2/SiO2 nanocolumnar layers deposited at oblique angles are fabricated in slanted, chiral, and zig-zag configurations by rotating azimuthally the substrate from one layer to the next. Multilayer systems formed by the stacking of 3 and 15 alternant thin films of these two oxides are morphologically characterized by scanning electron microscopy (SEM) and structurally by GISAXS. This technique has provided a means to determine various vertical and lateral correlation lengths and to assess the anisotropic electron density distribution along the structural elements existing in the multilayers. This information can be systematically used to account for the actual arrangement of nanostructural elements in multilayer systems.

September, 2018 · DOI: 10.1002/admi.201800530

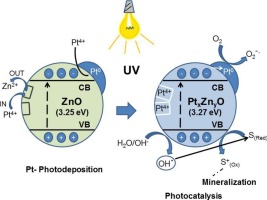

Fotocatálisis Heterogénea: Aplicaciones

ZnO and Pt-ZnO photocatalysts: Characterization and photocatalytic activity assessing by means of three substrates

Jaramillo, C; Navio, J.A.; Hidalgo, M.C.; Macías, M.Catalysis Today, 313 (2018) 12-19 DOI: 10.1016/j.cattod.2017.12.009

Abstract

ZnO nanoparticles have been previously synthesized by a facile precipitation procedure by mixing aqueous solutions of Zn(II) acetate and dissolved Na2CO3 at pH ca. 7.0 without the addition of a template. The as-prepared ZnO material was anealed at 400 °C in air for 2 h. The Pt-ZnO catalysts (0.5 or 1.0 Pt wt.%) were obtained by photochemical deposition method on the surface of the prepared ZnO sample, using hexachloroplatinic acid (H2PtCl6). It has been shown that Zn2+ is lost from the photocatalyst to the medium and a replacement of the cationic vacancies of Zn2+ by Pt4+ cations occurs during the platinization process of the ZnO samples, regardless of whether the platinum metal photodeposition process. The as-prepared catalysts were characterized by XRD, BET, FE-SEM, TEM, XPS and diffuse reflectance spectroscopy (DRS). Three different probe molecules were used to evaluate the photocatalytic properties under UV-illumination: Methyl Orange and Rhodamine B were chosen as dye substrates and Phenol as a transparent substrate. High conversion values (ca. 100%) and a total organic carbon (TOC) removal of 90–96%, were obtained over these photocatalysts after 160 min of UV illumination. In general, it was observed that the presence of Pt on ZnO affects the lattice parameters and the crystallite size. Although ZnO can completely degrade RhB, MO and Phenol totally in ca. 60 min, the process is more efficient for Pt–ZnO photocatalysts.

September, 2018 · DOI: 10.1016/j.cattod.2017.12.009

Materiales Avanzados

Vitrification and derived glass-ceramics from mining wastes containing vermiculite and lithium aluminium phosphate

Rincon, JM; Callejas, P; Sanchez-Soto, PJ; Jordan, MMMaterials Letters, 227 (2018) 86-89 DOI: 10.1016/j.matlet.2018.05.001

Abstract

The waste vitrification of abandoned open sky vermiculite deposits has been considered by combining with a natural phosphate mineral residue. Several batches haven been designed from the composition system: Li2O-MgO-Al2O3-P2O5-SiO2 including some Fe2O3 and Fluoride. The resulting glasses are transparent and smooth green coloured, giving rise after TTT treatments to several opal, opaque glass-ceramics with iridescent surface. Full characterization has been carried out by XRD and electron microscopy with EDS, as well as by XPS spectroscopies, concluding that the main crystalline phases formed were alpha-cordierite and beta-spodumene. The surface of these glass-ceramics from vermiculiteamblygonite is enriched in Fe2O3. Compared to the parent glasses, the final glass-ceramics exhibited and improvement in fracture toughness.

September, 2018 · DOI: 10.1016/j.matlet.2018.05.001

Reactividad de Sólidos

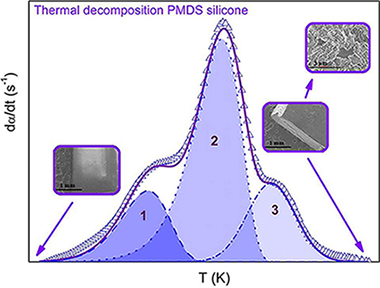

Combined kinetic analysis of multistep processes of thermal decomposition of polydimethylsiloxane silicone

Garcia-Garrido, C; Perez-Maqueda, LA; Criado, JM; Sanchez-Jimenez, PEPolymer, 153 (2018) 558-564 DOI: 10.1016/j.polymer.2018.08.045

Abstract

In this work, we studied the thermal decomposition of a widely employed silicone elastomer, polydimethylsiloxane, in an inert atmosphere. This silicone elastomer has several applications due to its high thermal stability such as MEMS (microelectromechanical systems) precursors, microfluidic components, adhesives, lubricants, and precursors for non-porous ceramics. Therefore, a reliable description of the thermal decomposition kinetics is important to prevent or control the decomposition in such applications. While the decomposition has been amply reported as a complex process, most kinetic studies published on this system use simplified methods that avoid the fact that the entire process cannot be described by a single kinetic triplet. Here, we have studied the decomposition process by first separating the overall reaction into its three constituent steps which were subsequently analysed independently. The deconvolution was carried out using Fraser-Suzuki function that is capable of fitting an asymmetric peak fitting function. The resulting kinetic parameters proved to be able to reconstruct the original experimental curves but are also capable of producing accurate predictions of curves recorded at heating schedules different from those employed to record the experimental data used in the kinetic analysis. Finally, it was found that the rate limiting step of all stages is the diffusion of the gases released during the polymer decomposition through the transforming polymeric matrix.

September, 2018 · DOI: 10.1016/j.polymer.2018.08.045

Química de Superficies y Catálisis

Operando DRIFTS-MS Study of WGS and rWGS Reaction on Biochar-Based Pt Catalysts: The Promotional Effect of Na

Santos, JL; Bobadilla, LF; Centeno, MA; Odriozola, JAC-Journal of Carbon Research, 4 (2018) 47 DOI: 10.3390/c4030047

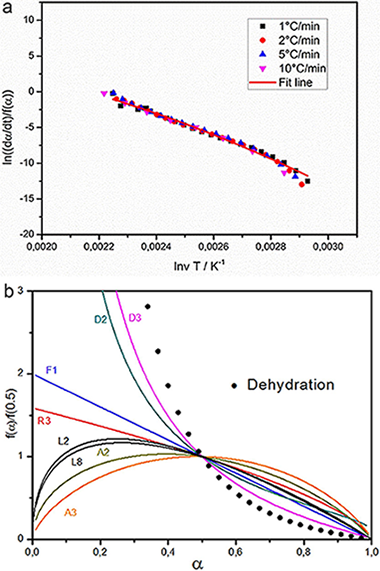

Reactividad de Sólidos

Synthesis, characterization and combined kinetic analysis of thermal decomposition of hydrotalcite (Mg6Al2(OH)(16)CO3 center dot 4H(2)O)

Yahyaoui, R; Jimenez, PES; Maqueda, LAP; Nahdi, K; Luque, JMCThermochimica Acta, 667 (2018) 177-184 DOI: 10.1016/j.tca.2018.07.025

Abstract

Here, a kinetic study of the thermal decomposition of synthesized hydrotalcite, Mg-6 Al-2 CO3(OH)(16)center dot H2O, has been carried out using thermogravimetric experiments in air atmosphere. It is shown that the thermal decomposition occurs in two well differentiated stages. The first one is a single-step dehydration process that comprises the release of four water molecules. On the other hand, the second stage is complex and corresponds to both dehydroxylation and decarbonation processes which occur simultaneously. The kinetic parameters describing all processes were calculated by means of a combined approach comprising isoconversional, model-fitting and deconvolution methods. It was concluded that dehydroxilation and decarbonization cannot be separated by TG experiments and the two stages contributing to the complex process do not apparently match the expected stoichiometry of the process. Therefore, it is proposed that such stages mark a change on the reaction mechanism due to the structural collapse of the laminar double hydroxide.

September, 2018 · DOI: 10.1016/j.tca.2018.07.025

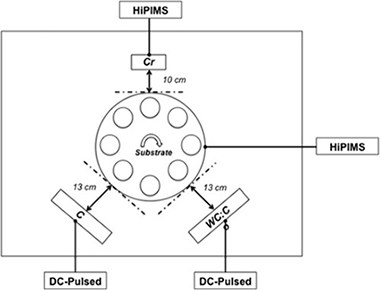

Tribología y Protección de Superficies

Adhesion enhancement of DLC hard coatings by HiPIMS metal ion etching pretreatment

Santiago, JA; Fernandez-Martinez, I; Wennberg, A; Molina-Aldareguia, JM; Castillo-Rodriguez, M; Rojas, TC; Sanchez-Lopez, JC; Gonzalez, MU; Garcia-Martin, JM; Li, H; Bellido-Gonzalez, V; Monclus, MA; Gonzalez-Arrabal, RSurface & Coatings Technology, 349 (2018) 787-796 DOI: 10.1016/j.surfcoat.2018.04.090

Abstract

Poor adhesion is a recurrent problem for the wider use of diamond-like carbon (DLC) coatings in industrial applications. In this work, we investigate the effectiveness of high-power impulse magnetron sputtering (HiPIMS) metal ion etching to improve the adhesion of DLC coatings on high speed steel substrates. The influence of HiPIMS pretreatment parameters, the metal ion selection for the process and the addition of bonding layers on the adhesion properties were studied. Daimler-Benz and nanoscratch test methods were used to evaluate the adhesion. The elemental composition, morphology and microstructure of the samples were evaluated by EELS, SEM, AFM and HRTEM. In general, samples pretreated with HiPIMS metal ion etching withstand larger critical loads than those pretreated by conventional Ar + glow discharge and bonding layers. The pretreatment is proven to be very effective at removing surface contaminants and providing a gradual interface. The selection of Cr over Ti contributes to a significant improvement on the adhesion due to the reduction of the oxygen level at the interface thus ensuring an optimal coating-substrate contact and a more compliant structure, which prevents the delamination failure.

September, 2018 · DOI: 10.1016/j.surfcoat.2018.04.090

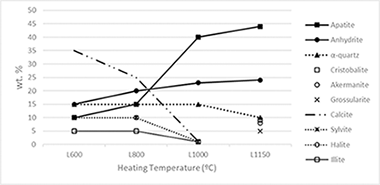

Materiales Avanzados

An approach to the heating dynamics of residues from greenhouse-crop plant biomass originated by tomatoes (Solanum lycopersicum, L.)

Garzon, E; Morales, L; Ortiz-Rodriguez, IM; Sanchez-Soto, PJEnvironmental Science and Pollution Research, 25 (2018) 25880-25887 DOI: 10.1007/s11356-018-2577-y

Abstract

The most representative of greenhouse-crop plant biomass residues of tomatoes (Solanum lycopersicum L.) were selected for this study by using X-ray fluorescence spectrometry (XRF) and X-ray powder diffraction (XRD). The heating dynamics in air in the 600-1150 degrees C range of these residues for the production of renewable energy and the resultant ashes have been investigated. A total of 11 elements were determined by XRF in the biomass ashes and some minor elements. The content of alkaline elements and chlorides decreased as increasing heating temperature and disappeared at 1150 degrees C. Alkaline salts, NaCl and KCl, were volatilized by heating since 800 degrees C. The total contents of S and P in the biomass ashes were associated to CaSO4, and a complex phosphate identified by XRD. CaCO3 present at 600 degrees C was decomposed to CaO with disappearance at 1000 degrees C. By heating, new silicates were formed by solid-state reactions in the biomass residue. The minor elements have been found in a relative proportion lower than 0.9wt.% and they characterized the obtained ashes, with potential use as micronutrients.

September, 2018 · DOI: 10.1007/s11356-018-2577-y

Nanotecnología en Superficies y Plasma

Sensing and biosensing with screen printed electrodes modified with nanostructured nickel oxide thin films prepared by magnetron sputtering at oblique angles

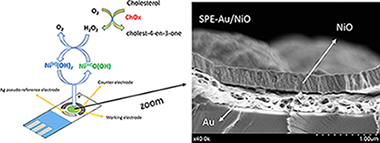

Salazar, P; Garcia-Garcia, FJ; Gonzalez-Elipe, ARElectrochemistry Communications, 94 (2018) 5-8 DOI: 10.1016/j.elecom.2018.07.020

Abstract

This work reports about the sensing and biosensing applications of a novel screen printed electrode (SPE) modified by nanostructured nickel oxide thin films obtained by reactive magnetron sputtering under an oblique angle configuration. Using these films as electrodes we demonstrate their ability to detect hydrogen peroxide under neutral pH conditions. Furthermore, as a proof-of-concept, NiO-modified SPEs have been developed and their cholesterol biosensing properties determined by cyclic voltammetry and chronoamperometry.

September, 2018 · DOI: 10.1016/j.elecom.2018.07.020

Química de Superficies y Catálisis

Improving the activity of gold nanoparticles for the water-gas shift reaction using TiO2-Y2O3: an example of catalyst design

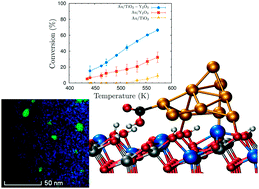

Plata, JJ; Romero-Sarria, F; Suarez, JA; Marquez, AM; Laguna, OH; Odriozola, JA; Sanz, JFPhysical Chemistry Chemical Physics, 20 (2018) 22076-22083 DOI: 10.1039/c8cp03706j

Abstract

In the last ten years, there has been an acceleration in the pace at which new catalysts for the water-gas shift reaction are designed and synthesized. Pt-based catalysts remain the best solution when only activity is considered. However, cost, operation temperature, and deactivation phenomena are important variables when these catalysts are scaled in industry. Here, a new catalyst, Au/TiO2-Y2O3, is presented as an alternative to the less selective Pt/oxide systems. Experimental and theoretical techniques are combined to design, synthesize, characterize and analyze the performance of this system. The mixed oxide demonstrates a synergistic effect, improving the activity of the catalyst not only at large-to-medium temperatures but also at low temperatures. This effect is related to the homogeneous dispersion of the vacancies that act both as nucleation centers for smaller and more active gold nanoparticles and as dissociation sites for water molecules. The calculated reaction path points to carboxyl formation as the rate-limiting step with an activation energy of 6.9 kcal mol(-1), which is in quantitative agreement with experimental measurements and, to the best of our knowledge, it is the lowest activation energy reported for the water-gas shift reaction. This discovery demonstrates the importance of combining experimental and theoretical techniques to model and understand catalytic processes and opens the door to new improvements to reduce the operating temperature and the deactivation of the catalyst.

September, 2018 · DOI: 10.1039/c8cp03706j

Materiales de Diseño para la Energía y Medioambiente

Iron-Catalyzed Graphitic Carbon Materials from Biomass Resources as Anodes for Lithium-Ion Batteries

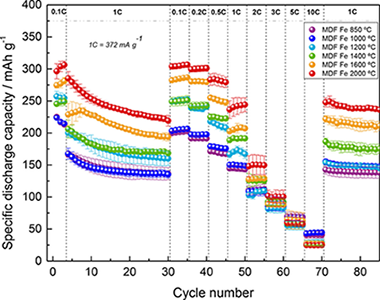

Gomez-Martin, A; Martinez-Fernandez, J; Ruttert, M; Heckmann, A; Winter, M; Placke, T; Ramirez-Rico, JChemsuschem, 11 (2018) 2776-2787 DOI: 10.1002/cssc.201800831

Abstract

Graphitized carbon materials from biomass resources were successfully synthesized with an iron catalyst, and their electrochemical performance as anode materials for lithium-ion batteries (LIBs) was investigated. Peak pyrolysis temperatures between 850 and 2000 degrees C were covered to study the effect of crystallinity and microstructural parameters on the anodic behavior, with a focus on the first-cycle Coulombic efficiency, reversible specific capacity, and rate performance. In terms of capacity, results at the highest temperatures are comparable to those of commercially used synthetic graphite derived from a petroleum coke precursor at higher temperatures, and up to twice as much as that of uncatalyzed biomass-derived carbons. The opportunity to graphitize low-cost biomass resources at moderate temperatures through this one-step environmentally friendly process, and the positive effects on the specific capacity, make it interesting to develop more sustainable graphite-based anodes for LIBs.

August, 2018 · DOI: 10.1002/cssc.201800831

Reactividad de Sólidos

Synthesis and characterization of SiC/Si3N4 composites from rice husks

Real, C; Cordoba, JM; Alcala, MDCeramics International, 44 (2018) 14645-14651 DOI: 10.1016/j.ceramint.2018.05.090

Abstract

SiC-Si3N4 composites have been obtained by carbothermal reduction of rice husk under a nitrogen-argon atmosphere at 1450 degrees C, which is a lower temperature than those used by other authors. On the other hand, tailoring the argon/nitrogen ratio led to the obtained of SiC-Si3N4 composites across the whole range of compositions. Phosphoric acid treatment permited the synthesis of the composite without a pyrolysis step. The final products were characterized by X-ray diffractometry, IR spectroscopy and scanning electron microscopy.

August, 2018 · DOI: 10.1016/j.ceramint.2018.05.090

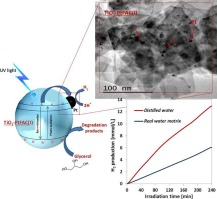

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Solar pilot plant scale hydrogen generation by irradiation of Cu/TiO2 composites in presence of sacrificial electron donors

Maldonado, MI; Lopez-Martin, A; Colon, G; Peral, J; Martinez-Costa, JI; Malato, SApplied Catalysis B-Environmental, 229 (2018) 15-23 DOI: 10.1016/j.apcatb.2018.02.005

Abstract

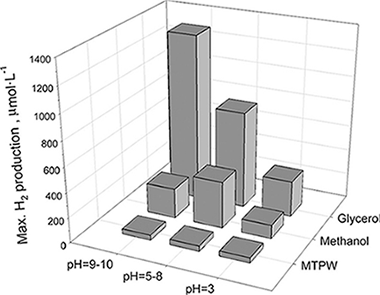

A Cu/TiO2 photocatalyst has been synthesised by reducing a Cu precursor with NaBH4 onto the surface of a sulphate pretreated TiO2 obtained by a sol-gel procedure. The catalyst, that shows a clearly defined anatase phase with high crystallinity and relatively high surface area, and contains Cu2O and CuO deposits on its surface, has been used to produce hydrogen in a solar driven pilot plant scale photocatalytic reactor. Different electron donor aqueous solutions (methanol, glycerol, and a real municipal wastewater treatment plant influent) have been tested showing similar or even higher energy efficiency than those obtained using more expensive noble metal based photocatalytic systems. The glycerol solutions have provided the best reactive environments for hydrogen generation.

August, 2018 · DOI: 10.1016/j.apcatb.2018.02.005

Reactividad de Sólidos

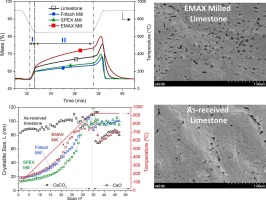

Effect of milling mechanism on the CO2 capture performance of limestone in the Calcium Looping process

Benitez-Guerrero, M; Valverde, JM; Perejon, A; Sanchez-Jimenez, PE; Perez-Maqueda, LAChemical Engineering Journal, 346 (2018) 549-556 DOI: 10.1016/j.cej.2018.03.146

Abstract

This work analyzes the relevant influence of milling on the CO2 capture performance of CaO derived from natural limestone. Diverse types of milling mechanisms produce contrasting effects on the microstructure of the CaO formed after calcination of the milled limestone samples, which affects crucially the kinetics of carbonation at conditions for CO2 capture. The capture capacity of CaO derived from limestone samples milled using either shear or impact based mills is impaired compared to as-received limestone. After calcination of the milled samples, the resulting CaO porosity is increased while crystallinity is enhanced, which hinders carbonation. Conversely, if the material is simultaneously subjected to intense impact and shear stresses, CaO porosity is promoted whereas CaO cristanillity is reduced, which enhances carbonation in both the reaction and solid-state diffusion controlled regimes.

August, 2018 · DOI: 10.1016/j.cej.2018.03.146

Reactividad de Sólidos

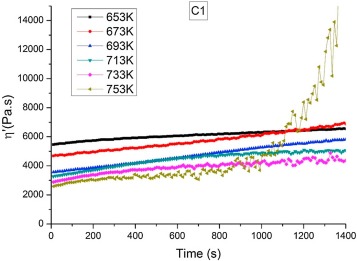

On the determination of thermal degradation effects and detection techniques for thermoplastic composites obtained by automatic lamination

Martin, MI; Rodriguez-Lence, F; Guemes, A; Fernandez-Lopez, A; Perez-Maqueda, LA; Perejon, AComposites part A-Applied science and manufacturing, 111 (2018) 23-32 DOI: 10.1016/j.compositesa.2018.05.006

Abstract

Automatic lay-up and in-situ consolidation with thermoplastic composite materials is a technology under research for its expected use in the profitable manufacturing of structural aeronautical parts. This study is devoted to analysing the possible effects of thermal degradation produced by this manufacturing technique.

Rheological measurements showed that there is negligible degradation in PEEK for the temperatures reached during the process. Thermogravimetric analysis under linear heating and constant rate conditions show that thermal degradation is a complex process with a number of overlapping steps. A general kinetic equation that describes the degradation of the material with temperature has been proposed and validated. Attenuated total reflectance Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy confirmed that there is no remarkable degradation. The use of a combination of in-situ and ex-situ experimental techniques, including kinetic modelling, not only provides reliable information about degradation but also allows setting optimal processing conditions.

August, 2018 · DOI: 10.1016/j.compositesa.2018.05.006

Reactividad de Sólidos

Electrical conduction mechanisms in graphene nanoplatelet/yttria tetragonal zirconia composites

Poyato, R; Osuna, J; Morales-Rodriguez, A; Gallardo-Lopez, ACeramics International, 44 (2018) 14610-14616 DOI: 10.1016/j.ceramint.2018.05.082

Abstract

Yttria tetragonal zirconia polycrystalline (3YTZP) ceramic composites with 5, 10 and 20 vol% graphene nano-platelets (GNPs) were prepared by spark plasma sintering (SPS) and their electrical conductivity as a function of temperature was characterized. The composites exhibit anisotropic microstructures so the electrical conductivity studies were carried out in two directions: perpendicular (sigma(perpendicular to)) and parallel (sigma(parallel to)) to the SPS pressing axis. The composites with 5 and 10 GNP vol% showed high electrical anisotropy, whereas the composite with 20 GNP vol % exhibited nearly isotropic electrical behavior. sigma(perpendicular to) shows metallic-type behavior in the composites with 10 and 20 vol% GNP revealing that charge transport takes place through defect-free GNPs. For the composite with 5 vol % GNP the observed semiconductor-type behavior was explained by a two dimensional variable range hopping mechanism. sigma(parallel to)shows metallic-type conductivity in the composite with 20 GNP vol% and positive d sigma(parallel to)/dT slope in the composites with 5 and 10 GNP vol%.

August, 2018 · DOI: 10.1016/j.ceramint.2018.05.082

Reactividad de Sólidos

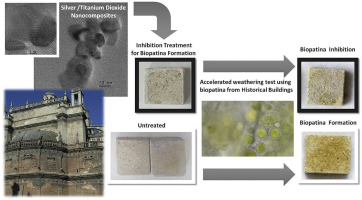

Synergy achieved in silver-TiO2 nanocomposites for the inhibition of biofouling on limestone

Becerra, J; Zaderenko, AP; Sayagues, MJ; Ortiz, R; Ortiz, PBuilding and Environment, 141 (2018) 80-90 DOI: 10.1016/j.buildenv.2018.05.020

Abstract

Biodeterioration of stone monuments is estimated to be as high as 20-30% of the total degradation suffered by Cultural Heritage constructions. With regard to this problem, bactericidal treatments are mainly based on cleaning. These processes, while effective in the short term, require frequent reapplications increasing potential damages to the monument. Silver nanoparticles offer many advantages over traditionally employed products, such as their prolonged biocide efficacy and their low toxicity to humans and environment. The aim of this study was to evaluate the applicability and effectiveness of seven nanocomposite treatments based on titanium dioxide and/or silver nanoparticles to prevent biodeterioration of limestone monuments. These nanocomposites were characterized by UV Visible spectrophotometry, Dynamic Light Scattering and Electron Microscopy. To assess their bactericidal activity, accelerated weathering tests were performed on limestones from the quarry of Utrera, a source widely employed in such iconic monuments as the Cathedral of Seville (Spain). Furthermore, the samples of biopatina employed in our assays stemmed from the fa ades of historical buildings from Seville. Our results show that silver and titanium dioxide nanocomposites stabilized by citrate achieve a high biocide effect while maintaining color alterations at a low level.

August, 2018 · DOI: 10.1016/j.buildenv.2018.05.020

Química de Superficies y Catálisis

Unravelling the Role of Oxygen Vacancies in the Mechanism of the Reverse Water-Gas Shift Reaction by Operando DRIFTS and Ultraviolet-Visible Spectroscopy

Bobadilla, LF; Santos, JL; Ivanova, S; Odriozola, JA; Urakawa, AACS Catalysis, 8 (2018) 7455-7467 DOI: 10.1021/acscatal.8b02121

Abstract

The reaction mechanism of the reverse water gas shift (RWGS) reaction was investigated using two commercial gold-based catalysts supported on Al2O3 and TiO2. The surface species formed during the reaction and reaction mechanisms were elucidated by transient and steady-state operando DRIFTS studies. It was revealed that RWGS reaction over Au/Al2O3 proceeds through the formation of formate intermediates that are reduced to CO. In the case of the Au/TiO2 catalyst, the reaction goes through a redox mechanism with the suggested formation of hydroxycarbonyl intermediates, which further decompose to CO and water. The Ti-3+ species, the surface hydroxyls, and oxygen vacancies jointly participate. The absence of carbonyl species adsorbed on gold particles during the reaction for both catalysts indicates that the reaction pathway involving dissociative adsorption of CO2 on Au particles can be discarded. To complete the study, operando ultraviolet visible spectroscopy was successfully applied to confirm the presence of Ti3+ and to understand the role of the oxygen vacancies of TiO2 support in activating CO2 and thus the subsequent RWGS reaction.

August, 2018 · DOI: 10.1021/acscatal.8b02121

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Structural Reversibility of LaCo1-xCuxO3 Followed by In Situ X-ray Diffraction and Absorption Spectroscopy

Pereniguez, Rosa; Ferri, DavideChemphyschem, 19 (2018) 1876-1885 DOI: 10.1002/cphc.201800069

Abstract

Combinations of perovskite-type oxides with transition and precious metals exhibit a remarkable self-regenerable property that could be exploited for numerous practical applications. The objective of the present work was to study the reversibility of structural changes of perovskite-type oxides under cyclic reducing/oxidizing atmosphere by taking advantage of the reducibility of LaCoO3. LaCoO3 +/- and LaCo0.8Cu0.2O3 +/- were prepared by ultrasonic spray combustion and were characterized by scanning electron microscopy (SEM), X-ray diffraction (XRD), X-ray absorption spectroscopy (XAS) and temperature-programmed reduction (TPR). XRD and XAS data confirmed that copper adopted the coordination environment of cobalt at the B-site of the rhombohedral LaCoO3 under the selected synthesis conditions. The structural evolution under reducing atmosphere was studied by insitu XRD and XANES supporting the assignment of the observed structural changes to the reduction of the perovskite-type oxide from ABB'O-3 (B'=Cu) to B'(0)/ABO(3) and to B'B-0(0)/A(2)O(3). Successive redox cycles allowed the observation of a nearly complete reversibility of the perovskite phase, i.e. copper was able to revert into LaCoO3 upon oxidation. The reversible reduction/segregation of copper and incorporation at the B-site of the perovskite-type oxides could be used in chemical processes where the material can be functionalized by segregation of Cu and protected against irreversible structural changes upon re-oxidation.

August, 2018 · DOI: 10.1002/cphc.201800069

Reactividad de Sólidos

Mechanochemical synthesis, structural, magnetic, optical and electrooptical properties of CuFeS2 nanoparticles

Dutkova, E; Bujnakova, Z; Kovac, J; Skorvanek, I; Sayagues, MJ; Zorkovska, A; Kovac, J; Balaz, PAdvanced Powder Technology, 29 (2018) 1820-1826 DOI: 10.1016/j.apt.2018.04.018

Abstract

The rapid mechanochemical synthesis of nanocrystalline CuFeS2 particles prepared by high-energy milling for 60 min in a planetary mill from copper, iron and sulphur elements is reported. The CuFeS2 nanoparticles crystallize in tetragonal structure with mean crystallite size of about 38 ± 1 nm determined by XRD analysis. HRTEM study also revealed the presence of nanocrystals with the size of 5–30 nm with the tendency to form agglomerates. The Raman spectrum confirms the chalcopyrite structure. Low temperature magnetic data for CuFeS2 support the coexistence of antiferromagnetic and paramagnetic spin structure. Moreover, the hysteresis loops taken at temperatures from 5 K to 300 K revealed a presence of very small amount of ferromagnetic phase, which seems to be associated with the non-consumed elemental Fe in as-prepared nanoparticles. The optical band gap of CuFeS2nanoparticles has been detected to be 1.05 eV, larger than band gap of the bulk material. The wider gap possibly resulted from the nano-size effect. Photoresponses of CuFeS2nanoparticles were confirmed by I-V measurements under dark and light illumination. It was demonstrated that mechanochemical synthesis can be successfully employed in the one step preparation of nanocrystalline CuFeS2 with good structural, magnetic, optical and electrooptical properties.

August, 2018 · DOI: 10.1016/j.apt.2018.04.018

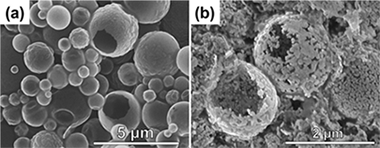

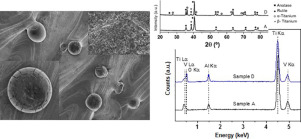

Reactividad de Sólidos

Surface modification of Ti-6Al-4V alloys manufactured by selective laser melting: Microstructural and tribo-mechanical characterization

Torres, Y; Sarria, P; Gotor, FJ; Gutierrez, E; Peon, E; Beltran, AM; Gonzalez, JESurface & Coatings Technology, 348 (2018) 31-40 DOI: 10.1016/j.surfcoat.2018.05.015

Abstract

Medical grade of both titanium (Ti) and Ti6A14V alloy are recognized as the metallic biomaterials with the better outcomes for clinical repair of bone tissue thanks to their suitable mechanical properties and corrosion resistance. However, those Ti advantages are not enough to avoid failure risks of bone implants; between 5 and 10% of Ti implants fail due to a deficient osseointegration, within 5 years of post-implantation. Most of these failures indicate the necessity of getting a better biomechanical-biofunctional balance. Microstructural and tribo-mechanical characterizations were performed on Ti6A14V samples obtained by selective laser melting and subjected to different surface treatments (thermal stress relief, acid etching, chemical treatment and thermochemical treatment). Scanning electron microscopy and X-ray diffraction were used for detailed characterization of the elemental composition, phase analysis and surface morphology. Micro-hardness and scratch tests were employed to evaluate the tribo-mechanical properties, which were improved after consecutive surface treatments. Protuberances with spherical morphology, as a remainder of the original powder, were present on the surface. The resulting modified surfaces were constituted by rutile (major phase) and anatase (minor phase). Submicro-nano-topographies were obtained after the chemical and thermochemical treatments.

August, 2018 · DOI: 10.1016/j.surfcoat.2018.05.015

Materiales Avanzados

The effect of vitreous phase on mullite and mullite-based ceramic composites from kaolin wastes as by-products of mining, sericite clays and kaolinite

Sanchez-Soto, PJ; Eliche-Quesada, D; Martinez-Martinez, S; Garzon-Garzon, E; Perez-Villarejo, L; Rincon, JMMaterials Letters, 223 (2018) 154-158 DOI: 10.1016/j.matlet.2018.04.037

Abstract

Mullite precursors were prepared using kaolin waste, sericite clay containing kaolinite and industrial kaolin with addition of alumina in a wet medium to synthesize mullite (72 wt% Al2O3 and 28 wt% SiO2). Uniaxial pressed bars of the powdered mullite precursors were fired in the range 1400-1600 degrees C with soaking times 30-120 min. The resultant materials were studied by XRD and SEM-EDX. Bulk densities, apparent porosities and flexural strengths in four points were determined in the fired bars at 1500, 1550 and 1600 degrees C. It was concluded that the thermal behaviour of these mullite precursors was influenced by the presence of impurities in the raw materials. These impurities originate a liquid phase forming a glassy phase which produces a progressive and enhanced densification of the mullite materials by reaction sintering at 1500-1600 degrees C. The technical properties were also influenced by the relative proportion of vitreous phase. The microstructure of characteristic mullite crystals was revealed by SEM. It was emphasized the use of kaolin waste by-products of mining and sericite clays as valuable raw materials for mullite preparation.

July, 2018 · DOI: 10.1016/j.matlet.2018.04.037

Fotocatálisis Heterogénea: Aplicaciones

Photo/Electrocatalytic Properties of Nanocrystalline ZnO and La–Doped ZnO: Combined DFT Fundamental Semiconducting Properties and Experimental Study

Ahsaine, A.H.; Slassi, A.; Naciri, Y.; Chennah, A.; Jaramillo‐Páez, C.; Anfar, Z.; Zbair, M.; Benlhachemi, A.; Navío, J.A.Chemistry Select, 3 (2018) 7778-7791 DOI: 10.1002/slct.201801729

Abstract

This work reports the synthesis of nanocrystalline ZnO and 5% La‐doped ZnO (La/ZnO) materials for photo/electrocatalytic degradation of Rhodamine B. The samples were characterized by X‐Ray diffraction, scanning and transmission electron microscopy, X‐Ray photoelectron spectroscopy and diffuse reflectance spectra. The effect of La doping on electronic structure was investigated using density functional theory calculations (DFT), La‐doped ZnO showed an n‐type metallic nature compared to pristine ZnO and La doping creates occupied states within the band gap edge. Under UV light, La/ZnO showed higher kinetic constant and efficiency than ZnO. A possible mechanism was elaborated on the basis of DFT and active trapping measurements. Different initial Rhodamine B concentration were studied to assess the electro‐oxidation of RhB. The electrochemical degradation of RhB over La/ZnO spindles electrode was pronounced with three time's high kinetic constant. The superior electro/photoactivity of La/ZnO was due to its unique morphology, high charge separation of the charge carriers and higher conductivity induced by La‐doping (intermediary levels). Superoxide ions and holes were the main active species for the photodegradation. Whereas, synergetic effect of hydroxyl radicals and hypochlorite ions were responsible of the high RhB electrocatalytic degradation.

July, 2018 · DOI: 10.1002/slct.201801729

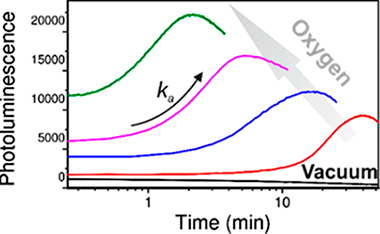

Materiales Ópticos Multifuncionales - Nanotecnología en Superficies y Plasma

Origin of Light-Induced Photophysical Effects in Organic Metal Halide Perovskites in the Presence of Oxygen

Anaya, M; Galisteo-Lopez, JF; Calvo, ME; Espinos, JP; Miguez, HJournal of Physical Chemistry Letters, 9 (2018) 3891-3896 DOI: 10.1021/acs.jpclett.8b01830

Abstract

Herein we present a combined study of the evolution of both the photoluminescence (PL) and the surface chemical structure of organic metal halide perovskites as the environmental oxygen pressure rises from ultrahigh vacuum up to a few thousandths of an atmosphere. Analyzing the changes occurring at the semiconductor surface upon photoexcitation under a controlled oxygen atmosphere in an X-ray photoelectron spectroscopy (XPS) chamber, we can rationalize the rich variety of photophysical phenomena observed and provide a plausible explanation for light-induced ion migration, one of the most conspicuous and debated concomitant effects detected during photoexcitation. We find direct evidence of the formation of a superficial layer of negatively charged oxygen species capable of repelling the halide anions away from the surface and toward the bulk. The reported PL transient dynamics, the partial recovery of the initial state when photoexcitation stops, and the eventual degradation after intense exposure times can thus be rationalized.

July, 2018 · DOI: 10.1021/acs.jpclett.8b01830

Materiales Coloidales

Structural, optical and X-ray attenuation properties of Tb3+: BaxCe1-xF3-x (x=0.18-0.48) nanospheres synthesized in polyol medium

Gonzalez-Mancebo, D; Becerro, AI; Genevois, C; Allix, M; Corral, A; Parrado-Gallego, A; Ocana, MDalton Transactions, 47 (2018) 8382-8391 DOI: 10.1039/c8dt01202d

Abstract