Scientific Papers in SCI

2011

2011

Materiales y Procesos Catalíticos de Interés Ambiental y Energético - Fotocatálisis Heterogénea: Aplicaciones

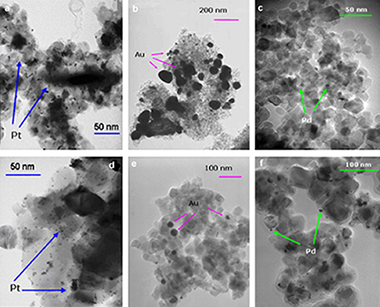

Comparative study of the photodeposition of Pt, Au and Pd on pre-sulphated TiO2 for the photocatalytic decomposition of phenol

Maicu, M; Hidalgo, MC; Colon, G; Navio, JAJournal of Photochemistry and Photobiology A: Chemistry, 217 (2011) 275-283 DOI: 10.1016/j.jphotochem.2010.10.020

Abstract

A comparative study of the photodeposition of Pt, Au and Pd under the same experimental conditions onto pre-sulphated and non-sulphated TiO2 was performed. Morphological and surface characterisation of the samples as well as photocatalytic activity for phenol photooxidation was studied. The influence of sulphate pre-treatment on the deposits size and dispersion onto the TiO2 surface, and photodeposition yields with the different metals were also analysed. The photocatalytic activity of the doped materials was then investigated, observing that catalytic behaviour can be correlated to physical characteristics of the samples determined by (XRD) X-ray diffraction, (XPS) X-ray photoelectron spectroscopy, (XRF) X-ray fluorescence spectrometry and (TEM) transmission electron microscopy. Sulphate pre-treatment was found to influence both the level of dispersion and the size of metal clusters on the TiO2 surface. Sulphation and metallisation of samples was found to produce a synergistic enhancement in photoactivity for the degradation of phenol. The photoactivity of the catalysts with respect to the doped metal species was ordered Pt > Pd > Au.

January, 2011 · DOI: 10.1016/j.jphotochem.2010.10.020

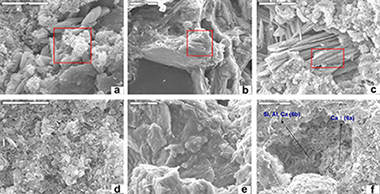

Materiales Nanoestructurados y Microestructura

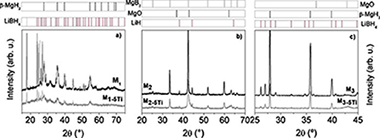

Combined x-ray photoelectron spectroscopy and scanning electron microscopy studies of the LiBH4-MgH2 reactive hydride composite with and without a Ti-based additive

Deprez, E; Munoz-Marquez, MA; de Haro, MCJ; Palomares, FJ; Soria, F; Dornheim, M; Bormann, R; Fernandez, AJournal of Applied Physics, 109 (2011) 014913 (10 pages) DOI: 10.1063/1.3525803

Abstract

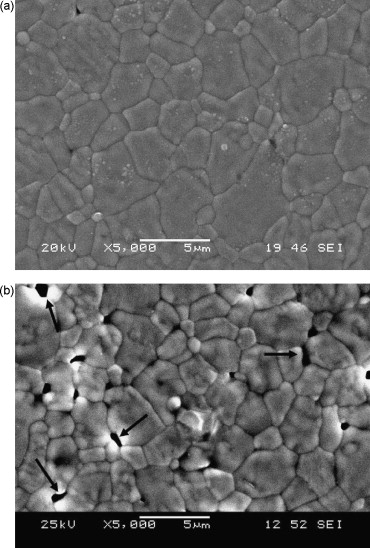

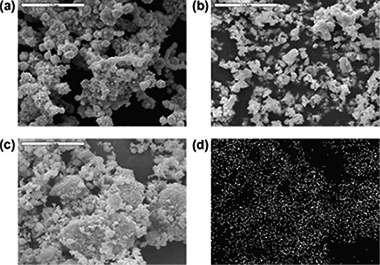

A detailed electronic and microstructural characterization is reported for the LiBH4-MgH2 reactive hydride composite system with and without titanium isopropoxide as additive. Surface characterization by x-ray photoelectron spectroscopy combined to a morphological study by scanning electron microscopy as well as elemental map composition analysis by energy dispersive x-ray emission are presented in this paper for the first time for all sorption steps. Although sorption reactions are not complete at the surface due to the unavoidable superficial oxidation, it has been shown that the presence of the additive is favoring the heterogeneous nucleation of the MgB2 phase. Ti-based phases appear in all the samples for the three sorption steps well dispersed and uniformly distributed in the material. Li-based phases are highly dispersed at the surface while the Mg-based ones appear, either partially covered by the Li-based phases, or forming bigger grains. Ball milling is promoting mixing of phases and a good dispersion of the additive what favors grain refinement and heterogeneous reactions at the interfaces.

January, 2011 · DOI: 10.1063/1.3525803

Química de Superficies y Catálisis

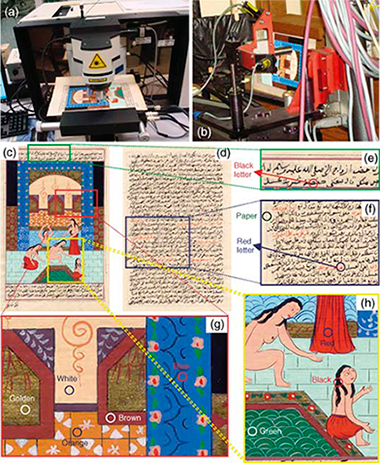

Forgery detection on an Arabic illuminated manuscript by micro-Raman and X-ray fluorescence spectroscopy

Duran, A; Franquelo, ML; Centeno, MA; Espejo, T; Perez-Rodriguez, JLJournal of Raman Spectroscopy, 42 (2011) 48-55 DOI: 10.1002/jrs.2644

Abstract

An Arabic manuscript, supposed to be from the 14th century, was investigated and its components (pigments and dyestuffs) characterised using micro-Raman and X-ray fluorescence (XRF) spectroscopy, the latter employing a portable XRF/X-ray diffraction (XRD) system. The presence of anatase, rutile, calcite, barite, zinc oxide, carbon black, vermilion, hematite, goethite, β-naphthol, copper phthalocyanine, pigmosol green and a brass-based pigment was detected in the different zones of the illuminated manuscript. The detection of titanium oxides, barite and organic synthetic colourants such as β-naphthol and copper phthalocyanine and derived compounds provides indisputable indication of forging, repainting or retouching after the 19th century in the image of the manuscript.

January, 2011 · DOI: 10.1002/jrs.2644

Materiales y Procesos Catalíticos de Interés Ambiental y Energético - Fotocatálisis Heterogénea: Aplicaciones

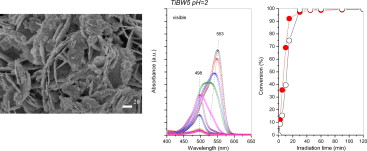

Novel Bi2WO6-TiO2 heterostructures for Rhodamine B degradation under sunlike irradiation

Lopez, SM; Hidalgo, MC; Navio, JA; Colon, GJournal of Hazardous Materials, 185 (2011) 1425-1434 DOI: 10.1016/j.jhazmat.2010.10.065

Abstract

Highly efficient Bi2WO6-TiO2 heterostructure is synthesized by means of a hydrothermal method having highly photoactivity for the degradation of Rhodamine B under sunlike irradiation. From the structural characterization it has been demonstrated that TiO2 is incorporated on the Aurivillius structure. Interesting synergetic effect between TiO2 and Bi2WO6 leads to an improved charge carrier separation mechanism, causing the excellent photocatalytic performance under sunlike irradiation. The photocatalytic performance of Bi2WO6 and Bi2WO6-TiO2 was compared under different irradiation conditions and using increasing Rhodamine B concentration up to 25ppm. After the photocatalytic analysis of both systems, the mineralization efficiency of the heterostructure appears significantly higher with respect to Bi2WO6.

January, 2011 · DOI: 10.1016/j.jhazmat.2010.10.065

Materiales Coloidales

A facile single-step procedure for the synthesis of luminescent Ln 3+:YVO4 (Ln = Eu or Er + Yb)-silica nanocomposites

Ocana, M; Cantelar, E; Cusso, FMaterials Chemistry and Physics, 125 (2011) 224-230 DOI: 10.1016/j.matchemphys.2010.09.011

Abstract

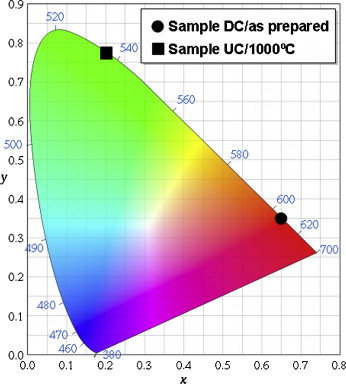

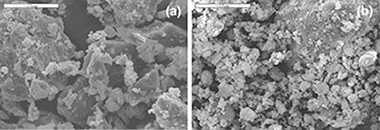

A simple and single-step method for the production of Ln-doped YVO 4 nanocrystals and their simultaneous encapsulation in a silica network based on the pyrolysis of liquid aerosols at 800 °C is reported. The procedure is illustrated for Yb,Er:YVO4-silica nanocomposites consisting of spherical particles, which present up-converted green luminescence after IR excitation whose efficiency increased on annealing up to 1000 °C due to the release of impurities (adsorbed water, and residual anions). XPS spectroscopy and TEM observations revealed that the surface of the composite particles was enriched in silica, which would facilitate their functionalisation required to use them in biological applications. The procedure can also be used to prepare other rare earth doped systems as illustrated for the case of Eu-doped YVO4/silica having down-converted red luminescence.

January, 2011 · DOI: 10.1016/j.matchemphys.2010.09.011

Reactividad de Sólidos

Synthesis and characterization of titanium-vanadium ternary nitride (Tix V1-x N)

Roldan, MA; Alcala, MD; Ortega, A; Real, CBoletín de la Sociedad Española de Cerámica y Vidrio, 50 (2011) 31-40 DOI: 10.3989/cyv.052011

Abstract

Titanium-Vanadium nitride (TiVN) has been prepared from carbothermal reduction of corresponding oxides and also by direct nitridation of a mix of two metals employing the ATVC method. The characterization of the final product by X-ray diffraction, scanning electron microscopy, electron energy loss (EELS), and X-ray absorption spectroscopy (XAS) is presented. The synthesis of the ternary nitride has been possible in all range of composition and the final product is obtained with nanometric particle size and a high microhardness after sintering.

January, 2011 · DOI: 10.3989/cyv.052011

Química de Superficies y Catálisis

Hydrogen production by methanol steam reforming on NiSn/MgO-Al2O3 catalysts: The role of MgO addition

Penkova, A; Bobadilla, L; Ivanova, S; Dominguez, MI; Romero-Sarria, F; Roger, AC; Centeno, MA; Odriozola, JAApplied Catalysis A-General,392 (2011) 184-191 DOI: 10.1016/j.apcata.2010.11.016

Abstract

The effect of the magnesia loading on the surface structure and catalytic properties of NiSn/MgO-Al2O3 catalysts for hydrogen production by methanol steam reforming has been investigated. The catalysts have been obtained by impregnation of γ-Al2O3 by the incipient wetness method, with variation of the MgO content. X-ray diffraction (XRD), BET surface area and H2-temperature programmed reduction (TPR) have been used to characterise the prepared catalysts. From this, it has been concluded that the incorporation of MgO results in the formation of MgAl2O4 spinel, which modifies the acid-base properties of the catalysts. The formation of Ni-Sn alloys after the reductive pre-treatment has also been evidenced. The influence of the temperature of reaction and of the MgO loading on the hydrogen production by reforming of methanol has been established. Moreover, tests of catalytic stability have been carried out for more than 20 h. The carbonaceous deposits have been examined by temperature-programmed oxidation (TPO). The analysis of the catalysts after reaction has confirmed the low level of carbon formation on these catalysts. In no case, carbon nanotubes have been detected on the solids.

January, 2011 · DOI: 10.1016/j.apcata.2010.11.016

2010

2010

Química de Superficies y Catálisis

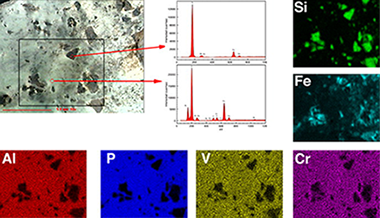

Physicochemical Characterization and Use of Wastes from Stainless Steel Mill

Dominguez, MI; Romero-Sarria, F; Centeno, MA; Odriozola, JAEnvironmental Progress & Sustainable Energy, 29 (2010) 471-480 DOI: 10.1002/ep.10435

Abstract

Several types of wastes are produced during the manufacture of stainless steel (slags, refractory bricks, and dust). Most of these wastes are not recycled but stored in security deposits or landfills depending on their environmental danger This article reports the study of the physicochemical and mineralogical properties of stainless steel wastes. Their possible uses are also discussed.

December, 2010 · DOI: 10.1002/ep.10435

Química de Superficies y Catálisis

Study of the stabilization of zinc phthalocyanine in sol-gel TiO2 for photodynamic therapy applications

Lopez, T; Ortiz, E; Alvarez, M; Navarrete, J; Odriozola, JA; Martinez-Ortega, F; Paez-Mozo, EA; Escobar, P; Espinoza, KA; Rivero, IANanomedicine-Nanotechnology Biology and Medicine, 6 (2010) 777-785 DOI: 10.1016/j.nano.2010.04.007

Abstract

Photodynamic therapy (PDT) has emerged as an alternative and promising noninvasive treatment for cancer. It is a two-step procedure that uses a combination of molecular oxygen, visible light, and photosensitizer (PS) agents; phthalocyanine (Pc) was supported over titanium oxide but has not yet been used for cell inactivation. Zinc phthalocyanine (ZnPc) molecules were incorporated into the porous network of titanium dioxide (TiO2) using the sol-gel method. It was prepared from stock solutions of ZnPc and TiO2. ZnPc-TiO2 was tested with four cancer cell lines. The characterization of supported ZnPc showed that phthalocyanine is linked by the N-pyrrole to the support and is stable up to 250 degrees C, leading to testing for PDT. The preferential localization in target organelles such as mitochondria or lysosomes could determine the cell death mechanism after PDT. The results suggest that nanoparticulated TiO2 sensitized with ZnPc is an excellent candidate as sensitizer in PDT against cancer and infectious diseases. From the Clinical Editor: Photodynamic therapy is a two-step procedure that uses a combination of molecular oxygen, visible light and photosensitizer agents as an alternative and promising non-invasive treatment for cancer. The results of this study suggest that nanoparticulated TiO2 sensitized with ZnPc is an excellent photosensitizer candidate against cancer and infectious diseases.

December, 2010 · DOI: 10.1016/j.nano.2010.04.007

Química de Superficies y Catálisis

Gold supported on metal-doped ceria catalysts (M = Zr, Zn and Fe) for the preferential oxidation of CO (PROX)

Laguna, OH; Sarria, FR; Centeno, MA; Odriozola, JAJournal of Catalysis, 276 (2010) 360-370 DOI: 10.1016/j.jcat.2010.09.027

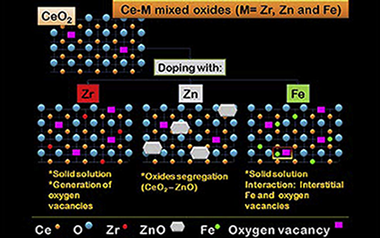

Abstract

A series of ceria oxides doped with 10 mol % of Zr Zn and Fe have been prepared by a pseudo sol-gel method throughout the thermal decomposition of the corresponding metallic propionates With these supports 1 wt % gold catalysts were prepared by the deposition-precipitation method All the solids were characterized by means of XRF N-2 adsorption XRD Raman spectroscopy and SEM techniques and their catalytic activity toward preferential oxidation of CO (PROX) reaction tested The results showed solid solution when doping with Zr and Fe and ZnO surface segregation in the case of Zn We demonstrate that gold dispersion depends on not only the oxygen vacancy concentration but also the nature of the doping agent Finally the catalytic activity was highly promoted by gold in all cases being the doped gold catalysts more active than Au/CeO2 at low temperature.

December, 2010 · DOI: 10.1016/j.jcat.2010.09.027

Variscite source and source analysis: testing assumptions at Pico Centeno (Encinasola, Spain)

Odriozola, CP; Linares-Catela, JA; Hurtado-Perez, VJournal of Archaeological Science, 37 (2010) 3146-3157 DOI: 10.1016/j.jas.2010.07.016

Abstract

The analysis of trade and their implications for understanding social interaction is a major research question of prehistoric research in Europe. Variscite is a rare mineral that offers an excellent opportunity to study trade and exchange patterns in prehistoric Europe through proveniencing of source material. In this paper we discuss the exploitation and exchange of variscite at Pico Centeno mining district during the Copper Age. XRF, XRD, and FTIR analyses of the mineral recovered at Pico Centeno mining district during archaeological survey provides a baseline mineral signature for the source and sub-sources, which were then compared to other Iberian sources and to 44 green beads from 8 megalithic tombs from two different regions, in order to test ‘provenance postulate’ and distribution models. Mineral sampled during survey at Pico Centeno mining district turned out to be pure variscite phases, while extremely varied for the studied green beads: variscite, muscovite, talc or chlorite. On testing ‘provenance postulate’ we have focused on compositional comparison of Pico Centeno’s variscite with reference from various geological sources of Western Europe. We found that the concentrations of trace elements do not allow us to establish the origin of the beads, as traditionally claimed, due to the strong natural variability on minor and trace elements of the sources. Instead we found after FTIR analysis, that different proportions of phosphate species, which results in P/Al ratios higher than 1, arose during the genesis of the variscite deposits and resulted from the associated pH and nature of the host-rocks, modifying the concentrations of PO43−, H2PO4− and HPO42−. Thus, the P/Al atomic ratio should be an indication of provenance as it is established during mineral genesis. This issue has not been addressed in any of the other studied sources where this ratio seems to be ≈1.

December, 2010 · DOI: 10.1016/j.jas.2010.07.016

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

A first study of the high-temperature plasticity of ceria-doped zirconia polycrystals

de Bernardi-Martin, S; Gomez-Garcia, D; Dominguez-Rodriguez, A; de Portu, GJournal of the European Ceramic Society, 30 (2010) 3357-3362 DOI: 10.1016/j.jeurceramsoc.2010.07.043

Abstract

Ceria zirconia ceramic alloys were sintered by high-temperature annealing, considering several synthesis temperatures to obtain a full-dense ceria zirconia ceramic material using a temperature as low as possible. It was found that fully density is achieved at temperatures of 1450 degrees C. Monolithic specimens were crept under compression at high temperatures. The creep results fitted an empirical constitutive equation consistent with a classical Ratchinger mechanism for grain switching. This result was confirmed through microstructural characterization of as-received and post-mortem specimens. Since the conventional Ashby-Verrall model is contrary to the mechanism controlling creep in other zirconia alloys, the results are considered in the framework of a new grain boundary sliding model, with particular discussion of the validity of that model for the ceria zirconia case.

December, 2010 · DOI: 10.1016/j.jeurceramsoc.2010.07.043

Nanotecnología en Superficies y Plasma

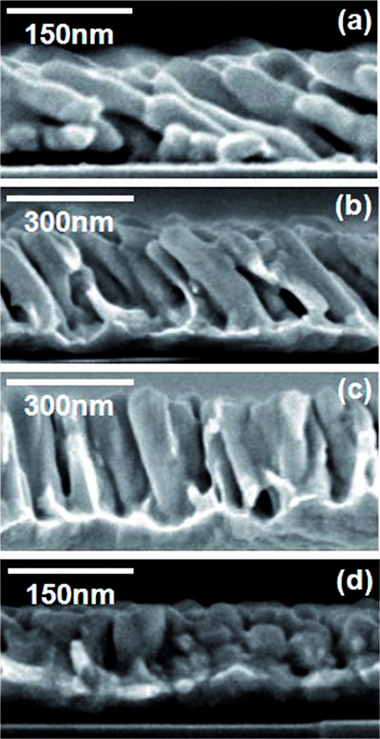

Band Gap Narrowing versus Formation of Electronic States in the Gap in N-TiO2 Thin Films

Romero-Gomez, P; Hamad, S; Gonzalez, JC; Barranco, A; Espinos, JP; Cotrino, J; Gonzalez-Elipe, ARJournal of Physical Chemistry C, 114 (2010) 22546-22557 DOI: 10.1021/jp104634j

Abstract

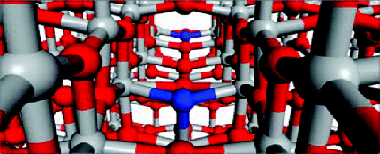

N-containing TiO2 thin films with different amounts of nitrogen have been prepared by plasma enhanced chemical vapor deposition (PECVD) by using different titanium precursors without (titanium isopropoxide, TTIP) and with (tetrakis diethylamino titanium, TDEAT and tetrakis dimethylamino titanium, TDMAT) nitrogen in their structures and different N-2/O-2 ratios as plasma gas. For low/high content of nitrogen, Ti-NO- and/or Ti-N-like species have been detected in the films by X-ray photoelectron spectroscopy (XPS). Their optical behavior is characterized by a red shift of their absorption edge when Ti-N species are a majority, and by an unmodified edge with localized absorption states in the gap when only Ti-NO-like species are present in the film. The experimental results have been interpreted by calculating the density of states of model systems consisting of a 2 x 2 x 3 repetition of the anatase unit cell. This basic structure incorporates nitrogen defects in either substitutional or interstitial lattice positions that are considered equivalent to the Ti-N- and Ti-NO-like species detected by XPS. To simulate the effect of, respectively, a low or a high concentration of nitrogen, calculations have been carried out by placing two nitrogen defects either in separated or in nearby positions of the anatase structure. The computational analysis reveals that the defects have different stabilization energies and confirm that an edge shift of the valence band is induced by the substitutional nitrogen centers, as observed when a high concentration of Ti-N species becomes incorporated into the films. In agreement with the experimental results, when only Ti-NO-like species are detected by XPS, no band gap narrowing is obtained by the calculations that predict the appearance of localized electronic states in the gap. The fact that only these latter films present water wetting angle photoactivity when irradiated with visible light supports that the presence of Ti-NO-like species is a required condition for visible light photoactivity.

December, 2010 · DOI: 10.1021/jp104634j

Materiales de Diseño para la Energía y Medioambiente

Bioactivation of biomorphous silicon carbide bone implants

Will J, Hoppe A, Muller FA, Raya CT, Fernandez JM, Greil PActa Biomaterialia, 6 (2010) 448-4494 DOI: 10.1016/j.actbio.2010.06.036

Abstract

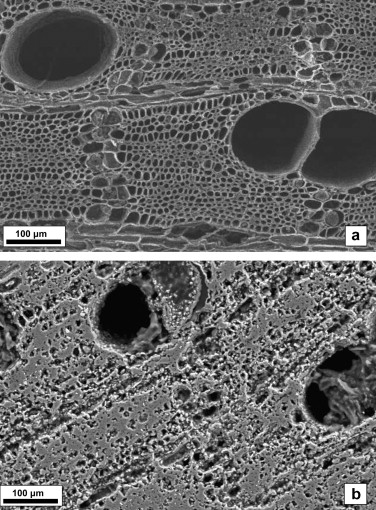

Wood-derived silicon carbide (SiC) offers a specific biomorphous microstructure similar to the cellular pore microstructure of bone. Compared with bioactive ceramics such as calcium phosphate, however, silicon carbide is considered not to induce spontaneous interface bonding to living bone. Bioactivation by chemical treatment of biomorphous silicon carbide was investigated in order to accelerate osseointegration and improve bone bonding ability. Biomorphous SiC was processed from sipo (Entrandrophragma utile) wood by heating in an inert atmosphere and infiltrating the resulting carbon replica with liquid silicon melt at 1450 °C. After removing excess silicon by leaching in HF/HNO3 the biomorphous preform consisted of β-SiC with a small amount (approximately 6 wt.%) of unreacted carbon. The preform was again leached in HCl/HNO3 and finally exposed to CaCl2 solution. X-ray photoelectron spectroscopy (XPS) and Fourier transform infrared analyses proved that oxidation of the residual carbon at the surface induced formation of carboxyl [COO-] groups, which triggered adsorption of Ca2+, as confirmed by XPS and inductively coupled plasma optical emission spectroscopy measurements. A local increase in Ca2+ concentration stimulated in vitro precipitation of Ca5(PO 4)3OH (HAP) on the silicon carbide preform surface during exposure to simulated body fluid, which indicates a significantly increased bone bonding activity compared with SiC.

December, 2010 · DOI: 10.1016/j.actbio.2010.06.036

Materiales de Diseño para la Energía y Medioambiente

Illization of kaolinite: The effect of pressure on the reaction rate

Mantovani, M; Becerro, AIClays and Clay Minerals, 58 (2010) 766-771 DOI: 10.1346/CCMN.2010.0580604

Abstract

Studies of the paragenesis of authigenic illite in arkosic sandstonesof various regions and ages have revealed that the illitizationof kaolinite is an important reaction accounting for the formationof authigenic illite in sandstones during burial diagenesis.The illitization of kaolinite takes place at an intermediateburial depth of 3–4 km, where pressure can reach valuesof 100 MPa ( 1000 bars). The purpose of the present study wasto analyze the effect of pressure on the rate of kaolinite illitizationin alkaline conditions. Hydrothermal reactions were conductedon KGa-1b kaolinite in KOH solution at 300°C and under pressuresof 500, 1000, and 3000 bars for 1 to 24 h. The visual examinationof the X-ray diffraction (XRD) patterns indicated a notableinfluence of pressure on the reaction rate. Molar percentagesof muscovite/illite formed at each time interval were calculatedfrom the analysis of two diagnostic XRD peaks, representingthe 060 reflections of kaolinite and muscovite/illite. The datawere modeled to obtain the initial rate of conversion at eachpressure. The results indicated that the initial rate of kaoliniteto muscovite/illite conversion is one order of magnitude greaterat 3000 bars than at 500 or 1000 bars. Comparison of these datawith those in the literature show a faster conversion rate (severalorders of magnitude) in an initially high-alkaline solutionthan in a near-neutral solution.

1000 bars). The purpose of the present study wasto analyze the effect of pressure on the rate of kaolinite illitizationin alkaline conditions. Hydrothermal reactions were conductedon KGa-1b kaolinite in KOH solution at 300°C and under pressuresof 500, 1000, and 3000 bars for 1 to 24 h. The visual examinationof the X-ray diffraction (XRD) patterns indicated a notableinfluence of pressure on the reaction rate. Molar percentagesof muscovite/illite formed at each time interval were calculatedfrom the analysis of two diagnostic XRD peaks, representingthe 060 reflections of kaolinite and muscovite/illite. The datawere modeled to obtain the initial rate of conversion at eachpressure. The results indicated that the initial rate of kaoliniteto muscovite/illite conversion is one order of magnitude greaterat 3000 bars than at 500 or 1000 bars. Comparison of these datawith those in the literature show a faster conversion rate (severalorders of magnitude) in an initially high-alkaline solutionthan in a near-neutral solution.

December, 2010 · DOI: 10.1346/CCMN.2010.0580604

Materiales Nanoestructurados y Microestructura

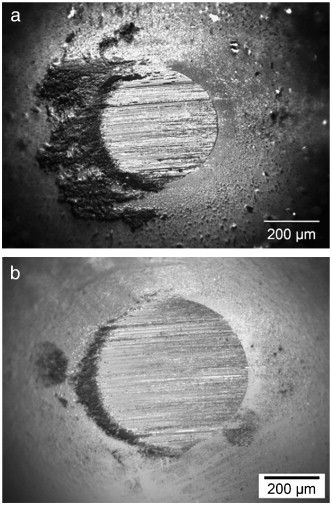

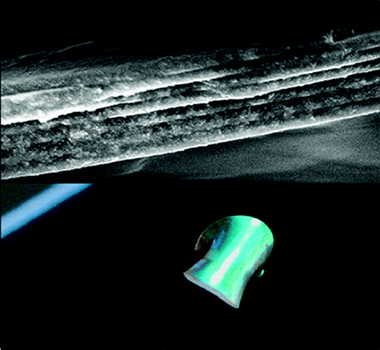

Effect of process parameters on mechanical and tribological performance of pulsed-DC sputtered TiC/a-C:H nanocomposite films

Shaha, KP; Pei, YT; Martinez-Martinez, D; Sanchez-Lopez, JC; De Hosson, JTMSurface and Coatings Technology, 205 (2010) 2633-2642 DOI: 10.1016/j.surfcoat.2010.10.020

Abstract

Mechanical, structural, chemical bonding (sp(3)/sp(2)). and tribological properties of films deposited by pulsed-DC sputtering of Ti targets in Ar/C2H2 plasma were studied as a function of the substrate bias voltage, Ti-target current, C2H2 flow rate and pulse frequency by nanoindentation, Raman spectroscopy and ball-on-disc tribometry. The new findings in this study comprise: dense, column-free, smooth, and ultra-low friction TiC/a-C:H films are obtained at a lower substrate bias voltage by pulsed-DC sputtering at 200 and 350 kHz frequency. The change in chemical and phase composition influences the tribological performance where the TiC/a-C:H films perform better than the pure a-C:H films. In the case of TiC/a-C:H nanocomposite films, a higher sp(2) content and the presence of TiC nanocrystallites at the sliding surface promote formation of a transfer layer and yield lower friction. In the case of a-C:H films, a higher sp(3) content and higher stress promote formation of hard wear debris during sliding, which cause abrasive wear of the ball counterpart and yield higher friction.

December, 2010 · DOI: 10.1016/j.surfcoat.2010.10.020

Nanotecnología en Superficies y Plasma

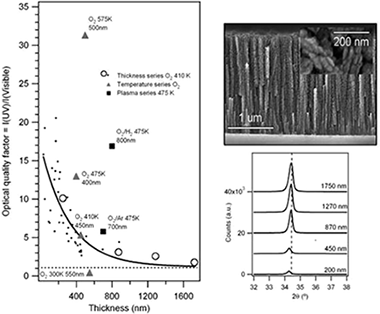

Tunable Nanostructure and Photoluminescence of Columnar ZnO Films Grown by Plasma Deposition

Romero-Gomez, P; Toudert, J; Sanchez-Valencia, JR; Borras, A; Barranco, A; Gonzalez-Elipe, ARJournal of Physical Chemistry C, 114 (2010) 20932-20940 DOI: 10.1021/jp103902u

Abstract

Nanoporous ZnO thin films presenting a tunable nanostructure and photoluminescence (PL) were grown by plasma enhanced vapor deposition on surface oxidized Si substrates. These films consist of c-axis oriented wurtzite ZnO nanocolumns whose topology, crystallinity, and PL can be tuned through the substrate temperature (varied in the 300-573 K range) and the nature of the plasma assistance (pure O-2, O-2/Ar, O-2/H-2, or O-2/N-2 mixture). In particular, these processing parameters influence the intensity of the UV and visible PL bands of the films, related to excitonic and defective radiative transitions, respectively. Increasing the substrate temperature enhances the UV PL and rubs out the visible PL due to the increase of grain size and the removal of interstitial defects. Additional tuning of the intensity ratio between the UV and visible bands can be done by controlling the film thickness. A decrease of the UV PL is observed when the films go thicker, an effect that is likely to be linked to the microstructure of the films rather than to their crystallinity that is improved upon increasing of the film thickness, as seen from PL spectroscopy and XRD measurements. Indeed, a gradient of stress, decreasing from the substrate to the surface, is evidenced and related to a concentration gradient of interstitial defects. The drawbacks of the thickness effect, which prohibits growing thick films with a high optical quality, can be bypassed by growing the films in a O-2/H-2 plasma.

December, 2010 · DOI: 10.1021/jp103902u

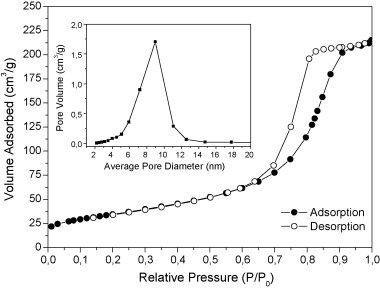

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Study of nanoporous catalysts in the selective catalytic reduction of NOx

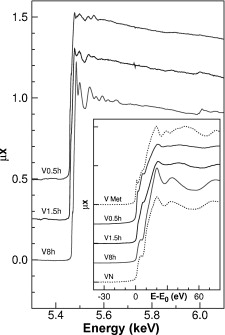

Rico, MJO; Moreno-Tost, R; Jimenez-Lopez, A; Rodriguez-Castellon, E; Pereniguez, R; Caballero, A; Holgado, JPCatalysis Today, 158 (2010) 78-88 DOI: 10.1016/j.cattod.2010.04.016

Abstract

Two SBA-15 type materials were synthesized using a low-cost route, a pure silica SBA-15 and an Al containing SBA-15 (with a Si/Al ratio of 10), where Al was added by a post-synthesis modification. The later solid was achieved without any significant loss in the textural properties of SBA-15, besides improving its properties as support of catalysts. Copper impregnated catalysts were prepared through the incipient wetness impregnation of the two supports. With both supports, the copper weight loading were 1, 3 and 6 wt%. The copper incorporation kept the support mesoporous structures, obtaining a better dispersion of the active phase in the containing aluminium support. All the catalysts showed a moderated catalytic activity in the SCR of NO with propane in presence of an excess of oxygen in the whole studied interval of temperatures and a much better performance was observed when using NH3 instead of propane. The changes of the active phases were studied by operando XAS spectroscopy. Factor analysis of in operando XANES results with sample SiAl_6 indicate that no Cu-0 was detected, but only Cu1+ and Cu2+. The temperature where the Cu1+/Cu2+ ratio is maximum occurs at the reaction temperature where the observed catalytic NO conversion is also maximum.

December, 2010 · DOI: 10.1016/j.cattod.2010.04.016

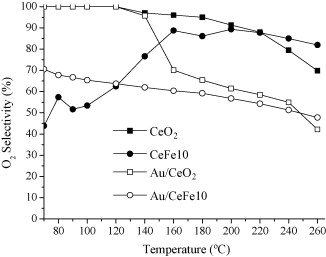

Química de Superficies y Catálisis

Iron-modified ceria and Au/ceria catalysts for Total and Preferential Oxidation of CO (TOX and PROX)

Laguna, OH; Centeno, MA; Arzamendi, G; Gandia, LM; Romero-Sarria, F; Odriozola, JACatalysis Today, 157 (2010) 155-159 DOI: 10.1016/j.cattod.2010.04.011

Abstract

Iron-modified ceria supports containing different molar percentages of Fe (0% 10% 25% and 50%) were synthesized by thermal decomposition of the metal propionates The formation of a Ce-Fe oxide solid solution is evidenced through XRF XRD BET and Raman spectroscopy For Iron contents above 25% the formation of alpha-Fe2O3 was detected pointing out the formation of the isolated oxides The catalytic activity of the Fe-modified catalysts in the Total Oxidation of CO reaction (TOX) is higher than for the bare CeO2 material The synergy between Ce and Fe shows a maximum for 10% Fe content (CeFe10) catalyst that shows the highest CO conversion per atom of Fe incorporated Gold catalyst was also prepared on CeFe10 and its catalytic activity compared with Au/CeO2 catalyst The addition of iron to the gold catalyst resulted in an enhancement of the catalytic activity for CO oxidation especially at low temperature This Au/CeFe10 catalyst was also active and selective with excellent stability in the Preferential Oxidation of CO (PROX) showing a higher CO conversion than the Au/CeO2 catalyst at temperatures below 150 C being hardly affected by the presence of CO2 and H2O in the gas stream.

November, 2010 · DOI: 10.1016/j.cattod.2010.04.011

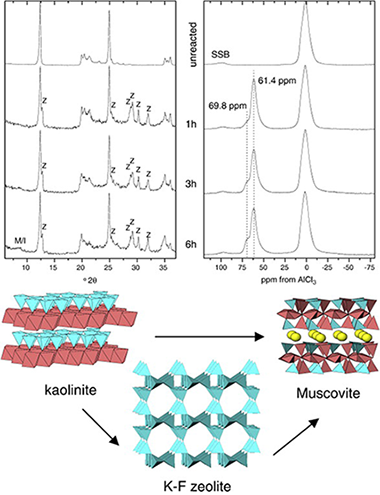

Materiales de Diseño para la Energía y Medioambiente

Effect of pressure on kaolinite illitization

Mantovani, M; Escudero, A; Becerro, AIApplied Clay Science, 50 (2010) 342-347 DOI: 10.1016/j.clay.2010.08.024

Abstract

The illitization of kaolinite at increasing pressures was followed by hydrothermal experiments of kaolinite in KOH solution at 300 degrees C for 12 h and pressures between 500 and 3000 bar XRD indicated a direct transformation of kaolinite into muscovite/illite with increasing pressure However the (27)AI MAS NMR spectra showed in addition to the muscovite/illite resonances the presence of a signal at 61 ppm that should correspond to a secondary phase not detected by XRD A second series of experiments at 300 degrees C and 1000 bar for 1 3 and 6 h was carried out to show direct evidence of such phase The XRD patterns of the products clearly showed the crystallization of K-F zeolite while the (27)AI MAS NMR spectra of these samples displayed a signal at 61 ppm that must correspond therefore to Al in the K-F zeolite structure In conclusion kaolinite transformed into muscovite/illite when submitted to hydrothermal reaction in KOH solution with increasing pressure with the formation of a secondary metastable phase called K-F zeolite whose coherent diffraction domains were too small as to be detected by XRD.Effect of pressure on kaolinite illitization

November, 2010 · DOI: 10.1016/j.clay.2010.08.024

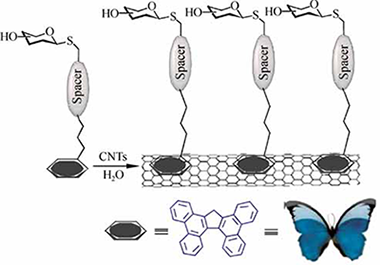

Nanotecnología en Superficies y Plasma

Improved Non-Covalent Biofunctionalization of Multi-Walled Carbon Nanotubes Using Carbohydrate Amphiphiles with a Butterfly-Like Polyaromatic Tail

Assali, M; Leal, MP; Fernandez, I; Romero-Gomez, P; Baati, R; Khiar, NNano Research, 3 (2010) 764-778 DOI: 10.1007/s12274-010-0044-2

Abstract

We have developed an efficient strategy for the non-covalent functionalization of multi-walled carbon nanotubes (MWCNTs) which allows a biomimetic presentation of carbohydrates on their surface by pi-pi stacking interactions. The strategy is based on the use of sugar-based amphiphiles functionalized with tetrabenzo[a,c,g,i] fluorene (Tbf), a polyaromatic compound with a topology that resembles a butterfly with open wings. The new carbohydrate-tethered Tbf amphiphiles have been synthesized in a straightforward manner using click chemistry. The reported method has been developed in order to improve the rather low ability of pyrene-based systems to exfoliate MWCNTs in water. By means of thermogravimetric analysis (TGA), ultraviolet (UV), infrared (IR), and fluorescence spectroscopies the interaction between MWCNTs and the Tbf group has been found to be stronger than those involving pyrene-based amphiphilic carbohydrates. The resulting aggregates with a multivalent sugar exposition on their surface are able to engage in specific ligand-lectin interactions similar to glycoconjugates on a cell membrane.

November, 2010 · DOI: 10.1007/s12274-010-0044-2

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

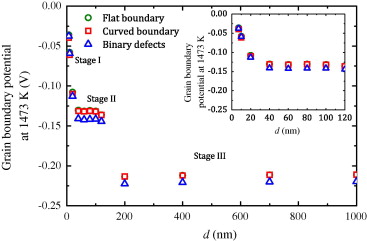

Segregation-induced grain boundary electrical potential in ionic oxide materials: A first principles model

D. Gómez-García, Juan J. Meléndez, Robert L. González-Romero, A. Domínguez-RodríguezActa Materialia, 58 (2010) 6404-6410 DOI: 10.1016/j.actamat.2010.08.002

Abstract

A first principles continuum analytical model for cationic segregation to the grain boundaries in complex ceramic oxides is presented. The model permits one to determine the electric charge density and the segregation-induced electric potential profiles through the grain and can be extrapolated to the range of nanostructured grain sizes. The theoretical predictions are compared with existing data for yttria-stabilized tetragonal zirconia polycrystals. The implications for physical properties (mainly high temperature plasticity and hardening behaviour) are then discussed.

November, 2010 · DOI: 10.1016/j.actamat.2010.08.002

Química de Superficies y Catálisis

Modified cryptomelane-type manganese dioxide nanomaterials for preferential oxidation of CO in the presence of hydrogen

Hernandez, WY; Centeno, MA; Romero-Sarria, F; Ivanova, S; Montes, M; Odriozola, JACatalysis Today, 157 (2010) 160-165 DOI: 10.1016/j.cattod.2010.03.010

Abstract

Transition metal (Cu Co Ni and Zn)-modified cryptomelane-type manganese dioxide nanomaterials were synthesized by the milling method The obtained solids have been characterized by means of Xray diffraction (XRD) scanning electron microscopy and transmission electron microscopy (SEM and TEM) N-2 adsorption-desorption measurements at 77 K Raman spectroscopy and temperature programmed reduction (TPR-H-2) showing similar structural and textural properties All the solids were active in the preferential oxidation of CO in the presence of hydrogen (PROX) being the modified with copper the most active The catalytic activity correlates fairly well with the TPR results finding higher CO conversion for the material with higher reducibility (OMS-Cu) The O-2 selectivity measured as ([CO](in)-[CO](out)/2[O-2](in)-[O-2](out)) x 100 is very similar for all synthesized materials.

November, 2010 · DOI: 10.1016/j.cattod.2010.03.010

Reactividad de Sólidos

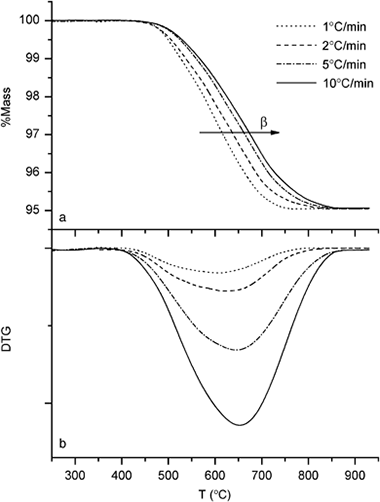

Quantitative Characterization of Multicomponent Polymers by Sample-Controlled Thermal Analysis

Sanchez-Jimenez, PE; Perez-Maqueda, LA; Crespo-Amoros, JE; Lopez, J; Perejon, A; Criado, JMAnalytical Chemistry, 82 (2010) 8875-8880 DOI: 10.1021/ac101651g

Abstract

This paper explores the potential of sample-controlled thermal analysis (SCTA) in order to perform compositional analysis of multicomponent polymeric materials by means of thermogravimetric experiments. In SCTA experiments, the response of the sample to the temperature determines the evolution of the temperature by means of a feedback system; thus, what is controlled is not the temperature time profile, as in conventional analysis, but rather the evolution of the reaction rate with time. The higher resolving power provided by the technique has been used for determining the composition of polymer blends composed of polyvinyl chloride (PVC) and different commercial plasticizers, a system where the individual components have very similar thermal stabilities, thereby rendering useless thermogravimetric experiments run under conventional conditions. Different SCTA procedures, such as constant rate thermal analysis (CRTA), which has received special attention, and high-resolution and stepwise isothermal analysis have been tested, and the results obtained have been compared with linear heating rate technique. It has been proven that CRTA can be used to effectively determine the exact composition of the blend.

November, 2010 · DOI: 10.1021/ac101651g

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Operando XAS and Raman study on the structure of a supported vanadium oxide catalyst during the oxidation of H2S to sulphur

Holgado, JP; Soriano, MD; Jimenez-Jimenez, J; Concepcion, P; Jimenez-Lopez, A; Caballero, A; Rodriguez-Castellon, E; Nieto, JMLCatalysis Today, 155 (2010) 296-301 DOI: 10.1016/j.cattod.2010.02.050

Abstract

The modification of crystalline phases of a vanadium oxide supported on mesoporous zirconium phosphate during the partial oxidation of H2S to sulphur has been studied by using an operando Raman-GC approach and XAS in reaction conditions. The catalyst, mainly presenting crystalline V2O5, is transformed during the oxidation of H2S at 200 degrees C, presenting crystals of V4O9, which is identified by the presence of a band at ca. 900 cm(-1) in the Raman spectra (using a 785 nm line of an Argon ion laser) and by the presence of a pre-edge at 5469.8 eV (and a main-edge at 5482.2 eV) in XANES spectra. At the same time, it is observed a high conversion of H2S to sulphur (the main reaction product) and SO2 (as minority). Both activity and selectivity depend on the time on stream. In this way, the selectivity to SO2 decreases from ca. 5 to 1% with the time on stream. This change could be explained on the basis of the nature of V-species: the initial presence of V5+-O-V5+ pairs and the appearance of V5+-O-V4+ pairs at high time on stream.

October, 2010 · DOI: 10.1016/j.cattod.2010.02.050

Materiales Nanoestructurados y Microestructura

Si-doped multifunctional bioactive nanostructured films

Shtansky, DV; Gloushankova, NA; Sheveiko, AN; Kiryukhantsev-Korneev, PV; Bashkova, IA; Mavrin, BN; Ignatov, SG; Filippovich, SY; Rojas, CSurface and Coatings Technology, 205 (2010) 728-739 DOI: 10.1016/j.surfcoat.2010.07.063

Abstract

Si-doped multifunctional bioactive nanostructured films (MuBiNaFs) were deposited by DC magnetron sputtering of composite TiC0.5 + CaO + Si (A) and TiC0.5 + CaO + Si3N4 (B) targets produced by self-propagating high-temperature synthesis method. The films were characterized in terms of their structure, elemental and phase composition using X-ray diffraction, scanning and transmission electron microscopy, electron energy loss spectroscopy, glow discharge optical emission spectroscopy. Raman, and IR spectroscopy. The Ti-Si-Ca-P-C-O-(N) films consisted of TiC(N) as a main phase with a minor amount of TiOx, SiNx, SiOx, SiC, and CaO phases probably mainly in amorphous state at the grain boundaries and COO- groups on the film surface. The excess of carbon atoms in the Ti-Si-Ca-P-C-O-N film (target A) precipitated in a DLC form. The films showed hardness in the range of 26-31 GPa, reduced Young's modulus of 200-270 GPa, and high percentage of elastic recovery of 60-71%. The best Ti-Si-Ca-C-O-N films exhibited low friction coefficient both in physiological solution and Dulbecko modified Eagle medium with fetal calf serum, hydrophilic properties, improved electrochemical characteristics, and excellent impact resistance. Nevertheless, the wear resistance of the Ti-Si-Ca-C-O-N films against Al2O3 ball was lower compared with the best Si-free MuBiNaFs. In vitro studies showed that the Si-doped Ti-Ca-C-O-N films possess improved osteoconductive characteristics during early stage of cell/material interaction. The film surface was highly adhesive for IAR-2 epithelial and MC3T3-E1 osteoblastic cells. The films revealed a high level of biocompatibility and biostability in experiments in vivo. The Ti-Si-Ca-C-O-N film (target A) did not show any bactericidal activity during cultivation of bacterial strains both on solid and in liquid Luria Bertani mediums. The film did not reveal any bactericidal and toxic activity against macrophages and therefore did not change bacterial status and defence system of macro-organisms.

October, 2010 · DOI: 10.1016/j.surfcoat.2010.07.063

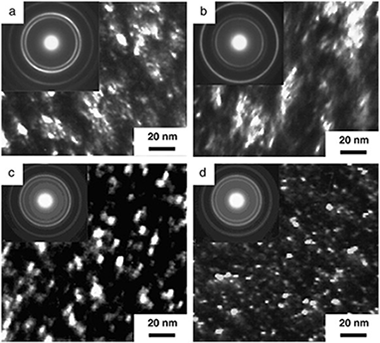

Materiales Nanoestructurados y Microestructura

Microstructural study of the LiBH4-MgH2 reactive hydride composite with and without Ti-isopropoxide additive

Deprez, E; Justo, A; Rojas, TC; Lopez-Cartes, C; Minella, CB; Bosenberg, U; Dornheim, M; Borrnann, R; Fernandez, AActa Materialia, 58 (2010) 5683-5694 DOI: 10.1016/j.actamat.2010.06.043

Abstract

An exhaustive microstructural characterization is reported for the LiBH4-MgH2 reactive hydride composite (RHC) system with and without titanium isopropoxide additive. X-ray diffraction with Rietveld analysis, transmission electron microscopy coupled to energy dispersive X-ray analysis, selected-area electron diffraction and electron energy loss spectroscopy are presented in this paper for the first time for this system for all sorption steps. New data are reported regarding average crystallite and grain size, microstrain, phase formation and morphology; these results contribute to the understanding of the reaction mechanism and the influence of the additives on the kinetics. Microstructural effects, related to the high dispersion of titanium-based additives, result in a distinct grain refinement of MgB2 and an increase in the number of reaction sites, causing acceleration of desorption and absorption reactions. Considerations on the stability of phases under electron beam irradiation have also been reported.

October, 2010 · DOI: 10.1016/j.actamat.2010.06.043

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

Superplasticity in nanocrystalline ceramics: pure grain boundary phenomena or not?

Dominguez-Rodriguez, A; Gomez-Garcia, D; Castillo-Rodriguez, M; Zapata-Solvas, E; Chaim, RInternational Journal of Materials Research, 101 (2010) 1215-1221 DOI: 10.3139/146.110401

Abstract

Superplasticity in ceramics has been the subject of intense research activity for the last two decades. Quite recently, the fabrication of fully dense nanocrystalline oxides with grain size below 100 nm enabled examination of their superplastic behaviour. This work presents a critical analysis of the plasticity of two important nanostructured oxide systems: MgO and yttria tetragonal zirconia polycrystals. A thorough comparison of their plastic deformation reveals that nano-structuring may be a necessary, but not a sufficient condition for superplasticity in ceramics as commonly assumed. Instead, the changes in the chemical composition and the transport properties, through the bulk and at grain boundaries, versus temperature and grain size can induce a rich variety of mechanical responses.

October, 2010 · DOI: 10.3139/146.110401

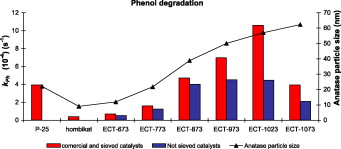

Fotocatálisis Heterogénea: Aplicaciones

Photocatalytic degradation of phenolic compounds with new TiO2 catalysts

Araña, J; Dona-Rodriguez, JM; Portillo-Carrizo, D; Fernandez-Rodriguez, C; Perez-Pena, J; Diaz, OG; Navio, JA; Macias, MApplied Catalysis B-Environmental, 100 (2010) 346-354 DOI: 10.1016/j.apcatb.2010.08.011

Abstract

New TiO2 catalysts have been synthesised by means of a sol-gel method in which aggregates have been selected before thermal treatment. Sieving and calcination temperature have been proved to be key factors in obtaining catalysts with greater photoactivity than that of Degussa P-25. These new catalysts have been characterized by means of transmission electron microscopy (TEM), BET surface area, diffuse reflectance spectroscopy (DRS). UV-vis spectroscopy, Fourier transformed infrared (FTIR) and X-ray diffraction (XRD). The different parameters studied were compared to those obtained from two commercial catalysts (Degussa P-25 and Hombikat-UV100). The photocatalytic efficiency of the new catalysts was evaluated by the degradation of various phenolic compounds using UV light (maximum around 365 nm, 9 mW). The catalyst sieved and calcinated at 1023 K, ECT-1023t, showed phenol degradation rates 2.7 times higher than those of Degussa P-25. Also in the degradation of different phenolic compounds, this catalyst showed a higher activity than that of the commercial one. The high photoactivity of this new catalyst has been attributed to the different distribution of surface defects (determined from FTIR studies) and its increased capacity to yield H2O2.

October, 2010 · DOI: 10.1016/j.apcatb.2010.08.011

Hydraulic structures of the Roman Mithraeum house in Augusta emerita, Spain

Robador, MD; Perez-Rodriguez, JL; Duran, AJournal of Archaeological Science, 37 (2010) 2426-2432 DOI: 10.1016/j.jas.2010.05.003

Abstract

This paper deals with some of the hydraulic structures of Augusta Emerita (Merida, Spain), specifically those found in the Mithraeum House. In particular, we describe and characterise the hydraulic mortars and coatings of the viridarium water channel. The recipient of the channel was covered with two hydraulic mortars and a finishing coating. Hydrated lime was used as binder. Calcite grains with different morphology have been observed in the mortars studied. The siliceous aggregate was composed of quartz, mica and feldspars. Ceramic fragments, which were added to the mortar to improve its hydraulic properties, were composed of quartz, mica, iron oxides, anorthite and an amorphous phase; aluminium-iron silicates were used as raw materials for their manufacture. We discuss the interactions between the hydrated lime and the surface of the ceramics in the mortars.

October, 2010 · DOI: 10.1016/j.jas.2010.05.003

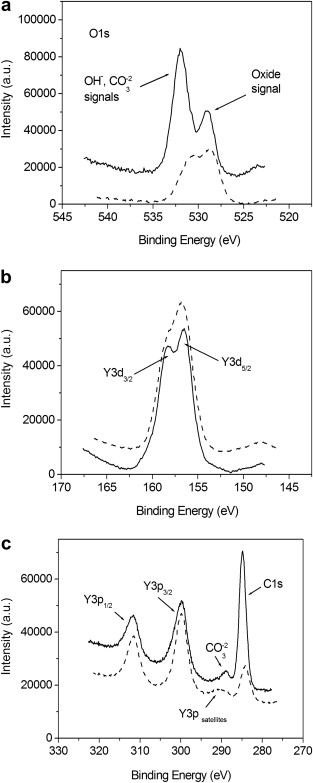

Nanotecnología en Superficies y Plasma - Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Structure and microstructure of EB-PVD yttria thin films grown on Si (111) substrate

Hartmanova, M; Jergel, M; Holgado, JP; Espinos, JPVacuum, 85 (2010) 535-540 DOI: 10.1016/j.vacuum.2010.09.003

Abstract

Structure and microstructure of yttria thin films grown by electron beam physical vapour deposition on a stationary Si (111) substrate at room temperature (RT), 500 degrees and 700 degrees C, were investigated by the grazing-incidence X-ray diffraction and scanning electron microscopy, respectively. X-ray photoelectron spectroscopy provided information on the surface contamination from the atmosphere and the oxidation state. A strong effect of the deposition temperature and the vapour flux incidence angle was found. The film deposited at RT is polycrystalline with very fine grains of the body-centered cubic (bcc) crystallographic symmetry. An increase of deposition temperature results in a rapid growth of bcc grains with an improved crystalline structure. Moreover, the based-centered monoclinic phase appears for the deposition temperature of 700 degrees C. Preferred grain orientation (texture) with two main components, (400) and (622), was observed in the films deposited at 500 degrees C whereas no texture was found for 700 degrees C. The microstructure exhibits the columnar feather-like structure of different degrees of perfection which can be explained by the shadowing effects caused by an oblique vapour flux incidence angle. Surface morphology of the films is governed by a combination of the triangular and four-sided (square) columns. All films were found to be dense with a little porosity between the columns.

October, 2010 · DOI: 10.1016/j.vacuum.2010.09.003

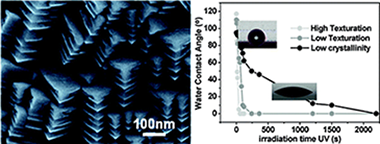

Nanotecnología en Superficies y Plasma

Wetting Properties of Polycrystalline TiO2 Surfaces: A Scaling Approach to the Roughness Factors

Borras, A; Gonzalez-Elipe, ARLangmuir, 26 (2010) 15875-15882 DOI: 10.1021/la101975e

Abstract

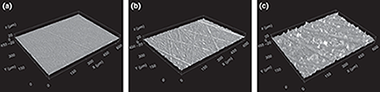

This work presents a thorough study on the wettability of polycrystalline anatase TiO2 thin films prepared at 250 degrees C in a microwave plasma enhanced chemical vapor deposition (MW-PECVD) reactor with Ar/O-2 plasmas. Anatase polycrystalline thin films with different microstructures, textures, and surface roughness were obtained as a function of their thickness. The water contact angle of the samples was analyzed within the assumptions of the Wenzel, Cassie, and Miwa models to ascertain the effect of roughness and other surface heterogeneities on their characteristic parameters. The roughness factors defined in the different models were calculated from the atomic force microscopy (AFM) images of the films for two different observation scales within the premises of the dynamic scaling theories. The obtained results indicate that the wetting angle of an equivalent flat anatase surface with a value of 82 degrees can only be properly estimated for observation scales of 5 x 5 mu m(2) and using the Miwa model. The analysis of the UV induced hydrophilization of the surface state of the anatase films and the posterior recovery of the partially hydrophobic character of these surfaces in the absence of UV photons suggest a clear dependence of the light induced wettability on their texture and size of crystalline domains.

October, 2010 · DOI: 10.1021/la101975e

Nanotecnología en Superficies y Plasma

A transparent TMPyP/TiO2 composite thin film as an HCl sensitive optochemical gas sensor

Cano, M; Castillero, P; Roales, J; Pedrosa, JM; Brittle, S; Richardson, T; Gonzalez-Elipe, AR; Barranco, ASensors and Actuators B-Chemical, 150 (2010) 764-769 DOI: 10.1016/j.snb.2010.07.059

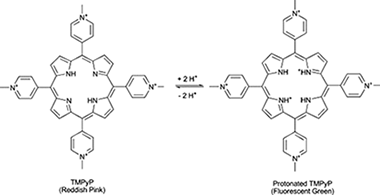

Abstract

Tetracationic porphyrin (TMPyP) molecules were incorporated Into an optically transparent TiO2 thin film prepared by Glancing Angle Physical Vapour Deposition (GAPVD) by simple infiltration (at pH 6 4) The preparation of optically transparent TMPyP/TiO2 composite thin films provides a method for the integration of the porphyrin molecules Into photonic devices for direct monitoring of gases Previously UV-visible and fluorescence spectral techniques have been used to study the reversible protonation of TMPyP in aqueous solution The optical spectrum of TMPyP shows an intense Soret band at 423 nm with a 22 nm red shift upon protonation by HCl The experimental conditions for monitoring the concentration of HCl gas by absorption spectroscopy have been optimized The maximum absorbance change was observed at the Sorer band wavelength A selected temperature of 80 C and a 300 s recovery period were found to be the optimum operating parameters (response time t(50) = 16 8 7 s) The composite with smaller surface concentration of TMPyP (Gamma = 03 x 10(-9) mol cm(-2)) presented the best detection limit (0 1 ppm) The response of the composite sensor was highly stable for several months.

October, 2010 · DOI: 10.1016/j.snb.2010.07.059

Fotocatálisis Heterogénea: Aplicaciones

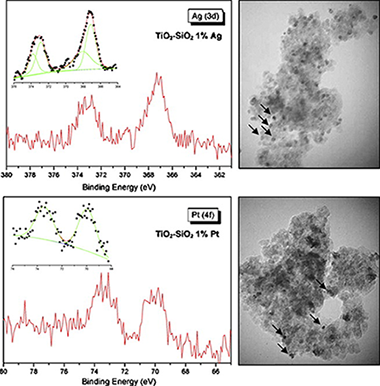

Characterisation and photocatalytic properties of titania-silica mixed oxides doped with Ag and Pt

Llano, B; Restrepo, G; Marin, JM; Navio, JA; Hidalgo, MCApplied Catalysis A-General, 387 (2010) 135-140 DOI: 10.1016/j.apcata.2010.08.021

Abstract

TiO2-SiO2 mixed oxides have been synthesised and modified by Ag and Pt deposition. Due to the effect of the silica on the mixed oxide, the prepared materials presented high surface areas and stabilised anatase as the only crystalline phase after calcination at 700 degrees C. Even using the same photodeposition experimental conditions, the yield for metal deposition depended highly on the metal considered, being much lower for Ag deposition. XPS studies permitted to estimate metal dispersion and oxidation state of the different samples, being both factors of high importance regarding photocatalytic improvement by metal deposition.

October, 2010 · DOI: 10.1016/j.apcata.2010.08.021

Materiales Ópticos Multifuncionales

Versatility and multifunctionality of highly reflecting Bragg mirrors based on nanoparticle multilayers

Olalla Sánchez-Sobrado, Mauricio E. Calvo and Hernán MíguezJournal of Materials Chemistry, 20 (2010) 8240-8246 DOI: 10.1039/c0jm01508c

Abstract

The use of both supported and flexible self-standing nanoparticle-based one dimensional photonic crystal films as effective frequency selective filters in the UV-vis-NIR is herein evaluated. The requirements to achieve a flat spectral response at the desired frequency range are analyzed and a synthetic route to realize materials with such properties presented. Strict control over the structural parameters yields multilayers in which the opening or closing of higher order photonic band gaps can be devised, thus leading to films capable of blocking the UV and NIR ranges simultaneously. Furthermore, the physico-chemical properties of the mirror can be modified to yield either moisture-repelling or, on the contrary, environmentally responsive optical filters. These materials present a great potential to be used as versatile and multifunctional optical elements.

October, 2010 · DOI: 10.1039/c0jm01508c

Nanotecnología en Superficies y Plasma

Tilt angle control of nanocolumns grown by glancing angle sputtering at variable argon pressures

Garcia-Martin, JM; Alvarez, R; Romero-Gomez, P; Cebollada, A; Palmero, AApplied Physics Letters, 97 (2010) - 173103 DOI: 10.1063/1.3506502

Abstract

We show that the tilt angle of nanostructures obtained by glancing angle sputtering is finely tuned by selecting the adequate argon pressure. At low pressures, a ballistic deposition regime dominates, yielding high directional atoms that form tilted nanocolumns. High pressures lead to a diffusive regime which gives rise to vertical columnar growth. Monte Carlo simulations reproduce the experimental results indicating that the loss of directionality of the sputtered particles in the gas phase, together with the self-shadowing mechanism at the surface, are the main processes responsible for the development of the columns.

October, 2010 · DOI: 10.1063/1.3506502

Química de Superficies y Catálisis

Synthesis of biodiesel from the methanolysis of sunflower oil using PURAL (R) Mg-Al hydrotalcites as catalyst precursors

Navajas, A; Campo, I; Arzamendi, G; Hernandez, WY; Bobadilla, LF; Centeno, MA; Odriozola, JA; Gandia, LMApplied Catalysis B-Environmental, 100 (2010) 299-309 DOI: 10.1016/j.apcatb.2010.08.006

Abstract

A series of commercial Mg-Al hydrotalcites have been used as catalyst precursors for the methanolysis of sunflower oil.The solids were characterized by low Mg/Al molar ratios in the 0.5-2.3 range. Additionally, a solid consisting mainly of Mg(OH)(2) but containing some Al (4.2 wt.%) was also employed. The as-received materials were inactive for biodiesel synthesis so calcination and rehydration in boiling water were considered as activation treatments. Among the calcined solids, only the material consisting of MgO was significantly active, achieving about 50% oil conversion after 24h at 60 degrees C, methanol/oil molar ratio of 12 and 2 wt.% of catalyst. The effects of the calcination temperature in the 350-700 degrees C range have been investigated; calcination at 500 degrees C led to the best catalytic performance. In the case of the rehydrated materials, only the solids with the highest Mg/Al molar ratios recovered a well-ordered layered double hydroxide structure. These samples showed an improved catalytic activity compared with their calcined counterparts. A good correlation between catalytic activity and the basic properties determined using Hammett indicators and benzoic acid titration has been found. Rehydrated hydrotalcites were slightly more selective to biodiesel (75%) at intermediate levels of oil conversion than the calcined counterparts (66%). It has been verified that no Mg or Al leaching in the reaction mixture took place; however, the rehydrated samples deactivated significantly. In the case of MgO, after washing and calcination. the recycled catalyst gave 68% of the original oil conversion.

October, 2010 · DOI: 10.1016/j.apcatb.2010.08.006

Materiales de Diseño para la Energía y Medioambiente

Aleuritic (9,10,16-trihydroxypalmitic) acid self-assembly on mica

Heredia-Guerrero, JA; San-Miguel, MA; Sansom, MSP; Heredia, A; Benitez, JJPhysical Chemistry Chemical Physics, 12 (2010) 10423-10428 DOI: 10.1039/c0cp00163e

Abstract

Aleuritic (9,10,16-trihydroxypalmitic) acid self-assembly on mica from solution has been studied using AFM, ATR-FTIR and MD simulations. The goal of this study is to define the role of hydroxyl groups in the interaction between molecules as reference data to understand the mechanism of formation of synthetic and natural biopolyesters from polyhydroxylated long chain carboxylic acids. In a confined structure, such as the one imposed by a vertically self-assembled layer on mica, aleuritic acid has a tendency to adopt a monolayer configuration ruled by the lateral interactions between molecules via the two secondary hydroxyl groups. This (2D) growth competes with the multilayer formation (3D), which is conditioned by the terminal primary hydroxyl group. As the self-assembly spatial constraint is relaxed, MD has shown that the structure tends to become an amorphous and crosslinked phase that can be characterized by topographic and friction force AFM data.

September, 2010 · DOI: 10.1039/c0cp00163e

Materiales Coloidales

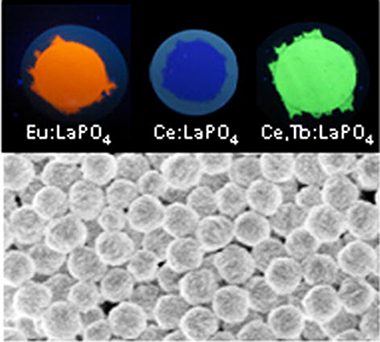

Citrate mediated synthesis of uniform monazite LnPO(4) (Ln = La, Ce) and Ln:LaPO4 (Ln = Eu, Ce, Ce plus Tb) spheres and their photoluminescence

Nuñez, NO; Liviano, SR; Ocaña, MJournal of Colloid and Interface Science, 349 (2010) 484-491 DOI: 10.1016/j.jcis.2010.05.079

Abstract

A simple method for the synthesis of spherical LaPO4 (monazite) particles with narrow size distribution and tailored size in the 150-500 nm range is reported. The procedure is based on a homogeneous precipitation process at low temperature (120 degrees C) from solutions containing La3+, citrate and phosphate ions under a very restrictive set of experimental conditions, which involves the use of La nitrate, citric acid and phosphoric acid as precursors and ethylene glycol as solvent. The growth mechanism of the spheres was investigated aiming at explaining the differences in particle size and shape observed when varying the experimental conditions. The applicability of this method for the synthesis of spherical particles of other lanthanide (Ce, Tb, Eu) phosphates is also analyzed. Finally, it is shown that the developed procedure can be used to dope the lanthanum phosphate particles with lanthanide cations, which resulted in spherical phosphors as illustrated for the Eu-doped, Ce-doped and Ce, Tb codoped systems, whose luminescent properties are also evaluated.

September, 2010 · DOI: 10.1016/j.jcis.2010.05.079

Nanotecnología en Superficies y Plasma

Surface nanostructuring of TiO2 thin films by high energy ion irradiation

Romero-Gomez, P; Palmero, A; Ben, T; Lozano, JG; Molina, SI; Gonzalez-Elipe, ARPhysical Review B, 82 (2010) - 115420 (8 pages) DOI: 10.1103/PhysRevB.82.115420

Abstract

The effects of a high ion dose irradiation on TiO2 thin films under different conditions of temperature and ion nature are discussed. We have shown that anatase TiO2 thin films irradiated with N+ ions at room temperature develop a typical microstructure with mounds and voids open to the surface whereas irradiations at 700 K generate a surface pattern of well-ordered nanorods aligned with the ion beam. The formation of these patterns is caused by the simultaneous effect of ion irradiation near the film surface and a film temperature favoring the structural mobilization of the defective network of the material. To explain these phenomena, a qualitative model has been proposed and further tested by irradiating the TiO2 thin films with F+ and S+ ions under different conditions. The obtained results demonstrate that ion irradiation techniques enable the formation of tilted nanorod surface patterns with lengths of about 100 nm on anatase TiO2 thin films.

September, 2010 · DOI: 10.1103/PhysRevB.82.115420

Materiales Coloidales

Uniform YF3:Yb,Er up-conversion nanophosphors of various morphologies synthesized in polyol media through an ionic liquid

Nuñez, NO; Quintanilla, M; Cantelar, E; Cusso, F; Ocaña, MJournal of Nanoparticle Research, 12 (2010) 2553-2565 DOI: 10.1007/s11051-009-9824-6

Abstract

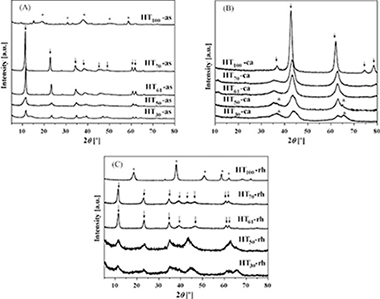

We describe a facile procedure for the synthesis at low temperature (120 A degrees C) of water-dispersible uniform YF3:Yb,Er up-conversion nanophosphors of various morphologies (rhombic and spheroidal) by homogeneous precipitation in polyol solutions containing different lanthanide salts and an ionic liquid (1-butyl, 2-methylimidazolium tetrafluoroborate) as fluoride source. It is shown that the shape of the obtained nanoparticles is mainly determined by the nature of both, the polyol and the lanthanide precursors, which also affects to their colloidal stability in water suspensions. These morphological differences are explained on the basis of a different mechanism of particle formation. The efficiency of the up-conversion processes in the synthesized rhombic and spheroidal nanoparticles is also comparatively analyzed and the observed differences are justified on the basis of the different impurities incorporated to the nanophosphors during their synthesis process.

September, 2010 · DOI: 10.1007/s11051-009-9824-6

Nanotecnología en Superficies y Plasma

On the microstructure of thin films grown by an isotropically directed deposition flux

Alvarez, R; Romero-Gomez, P; Gil-Rostra, J; Cotrino, J; Yubero, F; Palmero, A; Gonzalez-Elipe, ARJournal of Applied Physics, 108 (2010) 64316 DOI: 10.1063/1.3483242

Abstract

The influence of isotropically directed deposition flux on the formation of the thin film microstructure at low temperatures is studied. For this purpose we have deposited TiO2 thin films by two different deposition techniques: reactive magnetron sputtering, in two different experimental configurations, and plasma enhanced chemical vapor deposition. The obtained results indicate that films grown under conditions where deposition particles do not possess a clear directionality, and in the absence of a relevant plasma/film interaction, present similar refractive indices no matter the deposition technique employed. The film morphology is also similar and consists of a granular surface topography and a columnarlike structure in the bulk whose diameter increases almost linearly with the film thickness. The deposition has been simulated by means of a Monte Carlo model, taking into account the main processes during growth. The agreement between simulations and experimental results indicates that the obtained microstructures are a consequence of the incorporation of low-energy, isotropically directed, deposition particles.

September, 2010 · DOI: 10.1063/1.3483242

Química de Superficies y Catálisis

AISI 304 austenitic stainless steel monoliths: Modification of the oxidation layer and catalytic coatings after deposition and its catalytic implications

Martinez, LMT; Sanz, O; Centeno, MA; Odriozola, JAChemical Engineering Journal, 162 (2010) 1082-1090 DOI: 10.1016/j.cej.2010.07.005

Abstract

Monolithic CeO2 and Au/CeO2 catalysts were prepared using austenitic stainless steel (AISI 304) as metallic substrate. Both monolithic and powdered catalysts were characterized before and after CO oxidation reaction by N-2 adsorption desorption, XRD, SEM, TEM and GD-OES. Catalyst deposition on the stainless steel surface results in modifications of the catalyst, the oxide scale and the oxide scale/alloy interface through the interaction between the coating and the steel oxidation layer. Besides this, oxidation of the alloy is also detected. The extension and nature of these modifications depends on the catalyst nature, and on the reaction conditions. As a result of these modifications CO oxidation on Au/CeO2 catalysts is enhanced and gold surface dynamics is modified.

September, 2010 · DOI: 10.1016/j.cej.2010.07.005

Reactividad de Sólidos

Sintering by SPS of ultrafine TiCxN1-x powders obtained using mechanically induced self sustaining reaction

Borrell, A; Fernandez, A; Torrecillas, R; Cordoba, JM; Aviles, MA; Gotor, FJBoletin de la Sociedad Española de Cerámica y Vidrio, 49 (2010) 357-360 DOI: 10.3989/cyv.2010.v49.i5

Abstract

In this work high purity and nanometer character titanium carbonitride TiCxN1-x powders were obtained by mechanically induced self sustaining reaction (MSR) in a high-energy planetary ball mill, from a mixture of titanium with graphite or carbon nanofiber (CNFs) in a nitrogen atmosphere. A promising method for developing these materials is the coupling of the MSR with SPS sintering technique. The product is sintered at 1400 degrees C and 1700 degrees C, obtaining a completely dense monolithic ceramic (>99% t.d). In this work, the influence of SI'S treatment and carbon precursor on material microstructures was studied and the main mechanical properties of the end material were evaluated.

September, 2010 · DOI: 10.3989/cyv.2010.v49.i5

Nanotecnología en Superficies y Plasma

Tunable In-Plane Optical Anisotropy of Ag Nanoparticles Deposited by DC Sputtering onto SiO2 Nanocolumnar Films

Sanchez-Valencia, JR; Toudert, J; Borras, A; Lopez-Santos, C; Barranco, A; Feliu, IO; Gonzalez-Elipe, ARPlasmonics, 5 (2010) 241-250 DOI: 10.1007/s11468-010-9139-6

Abstract

This work reports an easy-to-handle method for growing two-dimensional assemblies of Ag nanostructures presenting a tunable in-plane optical anisotropy. Ag is deposited by DC sputtering in an Ar plasma at room temperature onto bundled nanocolumnar SiO2 thin films grown by glancing angle physical vapor deposition. In contrast with previously reported processes involving the grazing angle deposition of the metal, DC sputtering is performed at normal incidence. By varying the deposition angle of SiO2 and the Ar pressure, it was possible to tune the deposited amount of Ag and thus the topology of the Ag deposit from isolated spherical Ag nanoparticles with isotropic optical properties to strongly dichroic Ag nanostripes oriented along the bundling direction of the SiO2 nanocolumns. Based on simple calculations taking into account the shadowing effects during metal deposition, it is proposed that the width and shape of the tip of the bundled SiO2 nanocolumns influence significantly the metal local atom flux arriving to them and thus the final structure of the deposit.

September, 2010 · DOI: 10.1007/s11468-010-9139-6

Materiales Ópticos Multifuncionales - Nanotecnología en Superficies y Plasma

TiO2-SiO2 one-dimensional photonic crystals of controlled porosity by glancing angle physical vapour deposition

Gonzalez-Garcia, L; Lozano, G; Barranco, A; Miguez, H; Gonzalez-Elipe, ARJournal of Materials Chemistry, 20 (2010) 6408-6412 DOI: 10.1039/C0JM00680G

Abstract

Herein we present a synthetic route to attain porous one-dimensional photonic crystals of high optical quality. The method employed, based on the alternate deposition of TiO2 and SiO2 porous layers by glancing angle physical vapour deposition, yields a highly accessible interconnected pore network throughout the entire multilayer structure. Furthermore, it allows a strict control over the average size and density of the interstitial sites, which results in the precise tuning of the refractive index of the individual layers and thus of the optical response of the ensemble. The controlled environmental response of the multilayer is confirmed by the optical monitoring of the infiltration of liquids of different refractive index.

August, 2010 · DOI: 10.1039/C0JM00680G

Fotocatálisis Heterogénea: Aplicaciones

Determination of the local structure of a highly dispersed Pd-Nanosystem located on a titanium dioxide carrier

Kriventsov, VV; Novgorodov, BN; Yakimchuk, EP; Kochubey, DI; Zyuzin, DA; Simakova, IL; Chistyakov, AV; Zhmakin, VV; Bukhtenko, OV; Tsodikov, MV; Kozitsyna, NY; Vargaftik, MN; Moiseev, II; Maksimovskii, EA; Nechepurenko, SF; Navio, JA; Nikitenko, SGJournal of Surface Investigation-X-Ray Synchrotron and Neutron Techniques, 4 (2010) 636-639 DOI: 10.1134/S1027451010040166

Abstract

This work is devoted to a structural study of a highly dispersed Pd nanosystem, which is stabilized in the TiO2 matrix, by XAFS spectroscopy. Nanocomposite was prepared from bimetallic PdCo(mu-OOCMe)(4)(NCMe) precursor followed by processing in several ways: calcination in air and in argon and microwave irradiation. The local structure of Pd catalysts formed by different methods was studied. Possible structural models were considered in detail.

August, 2010 · DOI: 10.1134/S1027451010040166

Reactividad de Sólidos

Mechanochemical synthesis of vanadium nitride

Roldan, MA; Lopez-Flores, V; Alcala, MD; Ortega, A; Real, CJournal of the European Ceramic Society, 30 (2010) 2099-2107 DOI: 10.1016/j.jeurceramsoc.2010.04.008

Abstract

Vanadium nitride (VN) has been prepared by mechanosynthesis from vanadium metal under a pressurized nitrogen atmosphere in a short milling time. The characterization of the final product by X-ray diffraction, scanning electron microscopy, electron energy loss (EELS), and X-ray absorption spectroscopy (XAS) is presented. The final product, VN with 96% of purity, is obtained at room temperature with nanometric particle size and a very high microhardness after sintering. A relationship between microstructure and microhardness as well as a comparison between the VN obtained mechanical and thermal method is also presented.

August, 2010 · DOI: 10.1016/j.jeurceramsoc.2010.04.008

Materiales Nanoestructurados y Microestructura

Tailored synthesis of nanostructured WC/a-C coatings by dual magnetron sputtering

Abad, MD; Munoz-Marquez, MA; El Mrabet, S; Justo, A; Sanchez-Lopez, JCSurface and Coatings Technology, 204 (2010) 3490-3500 DOI: 10.1016/j.surfcoat.2010.04.019

Abstract

Nanostructured coatings with variable contents of tungsten carbide (WC) and amorphous carbon (a-C) are prepared by controlling the sputtering power ratio using WC and graphite targets. XRD and TEM/ED analysis shows that increasing the C incorporation. the WC nanocrystalline phases evolve from gamma-W2C to beta-WC1-x. Further C enrichment leads to a nanocomposite structure of small WC1-x crystals dispersed in a-C matrix. The a-C at.% is estimated by XPS analysis and correlated with the observed tribo-mechanical properties. The hardness and friction properties vary from hard/high friction (36-40 GPa; mu=0.6-0.8) to moderate-hard/low friction (16-20 GPa; mu similar to 0.2) coatings depending on the film composition. The transition point is found for a-C content of 10 at.%. This correlates with a change from nanocrystalline WC to nanocomposite WC1-x/a-C coatings. The overall study will help to understand the previous literature data and will serve as guide for a tailored synthesis of these WC/a-C nanocomposites.

August, 2010 · DOI: 10.1016/j.surfcoat.2010.04.019

Study of the Dehydroxylation-Rehydroxylation of Pyrophyllite

Perez-Rodriguez, JL; Duran, A; Sanchez-Jimenez, PE; Franquelo, ML; Perejon, A; Pascual-Cosp, J; Perez-Maqueda, LAJournal of the American Ceramic Society, 93 (2010) 2392-2398 DOI: 10.1111/j.1551-2916.2010.03750.x

Abstract

Pyrophyllite is a raw material of significant interest due to its large number of applications. Most of these applications require a thermal transformation of pyrophyllite; this thermal transformation implies the release of structural OH groups and the formation of new phases. In this paper, we report on the dehydroxylation of pyrophyllite and the reversibility of the process. A value of 224 +/- 16 kJ/mol for the dehydroxylation of pyrophyllite was obtained. In addition, it was observed that the partially or totally dehydroxylated pyrophyllite suffered a partial reversible rehydroxylation when cooled to room temperature. This rehydroxylation was substantiated by thermogravimetric measurements, while infrared spectroscopic studies showed that, during the rehydroxylation, the intensity of the OH band at 3675 cm-1 increased as two new bands at 3690 and 3702 cm-1 appeared. This rehydroxylation process was heavily influenced by the particle size of the pyrophyllite. Thus, smaller particles (< 1 mu m) showed a larger rehydroxylation percentage (about 12%), while the larger ones (20-40 mu m) showed a smaller percentage (about 1.6%). The extent of rehydroxylation also depended on the dehydroxylation temperature and reached a maximum value at 750 degrees C.

August, 2010 · DOI: 10.1111/j.1551-2916.2010.03750.x

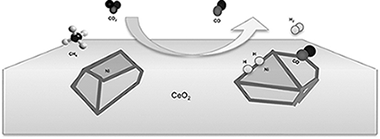

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Study of nanostructured Ni/CeO2 catalysts prepared by combustion synthesis in dry reforming of methane

Gonzalez-Delacruz, VM; Ternero, F; Pereniguez, R; Caballero, A; Holgado, JPApplied Catalysis A-General, 384 (2010) 1-9 DOI: 10.1016/j.apcata.2010.05.027

Abstract

This work reports the study of several catalysts of Ni-CeO2 active for dry methane reforming process (CH4 + CO2 -> 2CO + 2H(2)). The use of Ni as active phase is highly preferred, due to its availability, high activity and low cost, although its main lack is the coke formation on the surface of Ni metal particles, resulting in a severe deactivation. Here we report a new synthesis method that allows a simple, effective and fast way to prepare Ni-CeO2 catalysts, in a wide range of metallic loadings, resulting in all the cases in well-formed NiO crystallites with sizes in the range of 12-18 nm. The use of CeO2 as a support has been based on its massive use in TWC catalysts formulations, where it is recognized to activate CH4 and lower hydrocarbon dissociation. Moreover, CeO2 has been reported to have an intrinsic activity in the CH4 reforming reaction. Besides the metallic loading, several factors that control the preparation method of the catalyst have been varied, in order to optimize their performance. Most of the catalysts prepared show activity and selectivity values close to thermodynamic ones, maintaining a good stability on long periods of time and severe conditions. Nevertheless, formation of some carbon nano-fibers has been observed, which could result in a drawback for their application at large scale.

August, 2010 · DOI: 10.1016/j.apcata.2010.05.027

Reactividad de Sólidos

Kinetic model for thermal dehydrochlorination of poly(vinyl chloride)

Sanchez-Jimenez, PE; Perejon, A; Criado, JM; Dianez, MJ; Perez-Maqueda, LAPolymer, 51 (2010) 3998-4007 DOI: 10.1016/j.polymer.2010.06.020

Abstract

In this paper, a novel method for calculating degradation kinetics is presented. The method has been applied to the thermal dehydrochlorination of two different samples of PVC. It has been observed that this dehydrochlorination is complex and involves two different processes. A model that accounts for the entire dehydrochlorination is proposed. This model involves nucleation and growth and diffusion controlled mechanisms. The kinetic parameters are obtained from linear heating rate, isothermal and sample controlled thermal analysis experiments. Kinetic results obtained from the macroscopic thermal analysis measurements demonstrate the correlation between the kinetics of the thermal dehydrochlorination of PVC and the structure of this macromolecule.

August, 2010 · DOI: 10.1016/j.polymer.2010.06.020

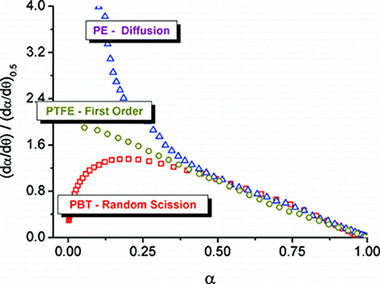

Reactividad de Sólidos

Generalized Kinetic Master Plots for the Thermal Degradation of Polymers Following a Random Scission Mechanism

Sanchez-Jimenez, PE; Perez-Maqueda, LA; Perejon, A; Criado, JMJournal of Physical Chemistry A, 114 (2010) 7868-7876 DOI: 10.1021/jp103171h

Abstract

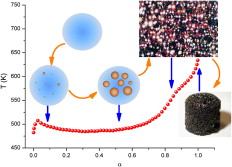

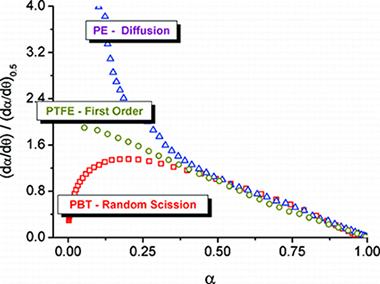

In this paper, the f(alpha) conversion functions for random scission mechanisms have been proposed to allow for the construction of generalized master plots suitable for these kinds of mechanisms. The master plots have been validated by their application to simulated data and to the thermal degradation of poly(butylene terephthalate), polyethylene, and poly(tetrafluoroethylene).

August, 2010 · DOI: 10.1021/jp103171h

Reactividad de Sólidos

Mechanochemical preparation of BaTiO3-Ni nanocomposites with high dielectric constant

Sanchez-Jimenez, PE; Perez-Maqueda, LA; Dianez, MJ; Perejon, A; Criado, JMComposite Structures, 92 (2010) 2236-2240 DOI: 10.1016/j.compstruct.2009.08.011

Abstract

A mechanochemical procedure is proposed for an easy preparation of a BaTiO3-Ni composite in a single step. BaTiO3 and Ni powders available in the market are mixed by dry ball milling producing a decrease of particle size and an evenly distribution of both phases. In the sintered pellets the nickel particles are homogeneously distributed into the BaTiO3 matrix and isolated from others Ni particles. The dielectric constant of the composite is considerably higher than that of the barium titanate. Moreover, the temperature of the ferroelectric <-> paraelectric transition of the BaTiO3-Ni composite here prepared is much lower than the one of the pure BaTiO3 single phase.

August, 2010 · DOI: 10.1016/j.compstruct.2009.08.011

Nanotecnología en Superficies y Plasma - Materiales Nanoestructurados y Microestructura - Tribología y Protección de Superficies

Characterization of Ti1-xAlxN coatings with selective IR reflectivity

Godinho, V; Philippon, D; Rojas, TC; Novikova, NN; Yakovlev, VA; Vinogradov, EA; Fernandez, ASolar Energy, 84 (2010) 1397-1401 DOI: 10.1016/j.solener.2010.04.021

Abstract