Artículos SCI

2016

2016

Nanotecnología en Superficies y Plasma

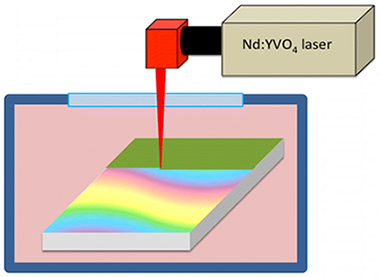

Laser Treatment of Nanoparticulated Metal Thin Films for Ceramic Tile Decoration

Rico, VJ; Lahoz, R; Rey-Garcia, F; Yubero, F; Espinos, JP; de la Fuente, GF; Gonzalez-Elipe, ARApplied Materials & Interfaces, 8 (2016) 24880-24886

Show abstract ▽

This paper presents a new method for the fabrication of metal-like decorative layers on glazed ceramic tiles. It consists of the laser treatment of Cu thin films prepared by electron-beam evaporation at glancing angles. A thin film of discontinuous Cu nanoparticles was electron-beam-evaporated in an oblique angle configuration onto ceramic tiles and an ample palette of colors obtained by laser treatment both in air and in vacuum. Scanning electron microscopy along with UV–vis–near-IR spectroscopy and time-of-flight secondary ion mass spectrometry analysis were used to characterize the differently colored layers. On the basis of these analyses, color development has been accounted for by a simple model considering surface melting phenomena and different microstructural and chemical transformations of the outmost surface layers of the samples.

Septiembre, 2016 | DOI: 10.1021/acsami.6b07469

Materiales Avanzados

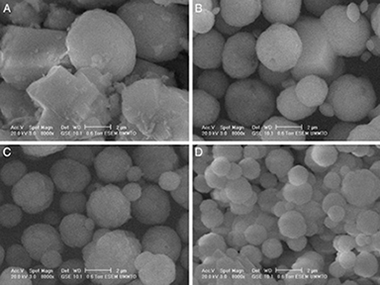

Preparation of calcium carbonate as nanoparticles from inorganic precursors and sucrose as additive with potential application as biomaterial

Takabait, F; Mahtout, L; Villarejo, LP; Hurtado, BC; Soto, PJSBoletin de la Sociedad Española de Cerámcia y Vidrio, 55 (2016) 179-184

Show abstract ▽

En esta comunicación se presentan unos primeros resultados de interés relevante sobre la obtención de carbonato de calcio precipitado como nanopartículas de los polimorfos vaterita y calcita. Se parte de precursores inorgánicos, nitrato de calcio tetrahidratado y bicarbonato de sodio, en presencia de sacarosa empleada como aditivo orgánico en disolución acuosa. Las fases cristalinas formadas se estudian mediante difracción de rayos X con un método cuantitativo y la morfología de las partículas obtenidas, mediante microscopia electrónica de barrido. Cuando no se emplea el aditivo orgánico se consigue la precipitación de calcita, polimorfo más estable termodinámicamente, como fase nanocristalina predominante (83%) mezclada con vaterita. Con una alta concentración del aditivo (67%) se obtiene vaterita como fase mayoritaria (> 98%). La utilización del aditivo en distinta proporción produce la formación de los 2 polimorfos de carbonato de calcio, siendo vaterita la fase predominante. La morfología de las partículas obtenidas muestra la formación de partículas nanoesféricas uniformes con contornos irregulares que se asocian a vaterita, así como partículas romboédricas de calcita cuando está presente, con potencial interés por su biocompatibilidad para su aplicación como biomateriales en implantes óseos.

Septiembre, 2016 | DOI: 10.1016/j.bsecv.2016.01.006

Química de Superficies y Catálisis

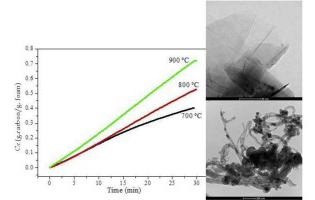

Growth of carbonaceous nanomaterials over stainless steel foams. Effect of activation temperature

Latorre, N; Cazana, F; Sebastian, V; Royo, C; Romeo, E; Centeno, MA; Monzon, ACatalysis Today, 273 (2016) 41-49

Show abstract ▽

Some of the problems that occur during the operation of chemical reactors based of structured catalytic substrates, as monoliths, foams, membranes, cloths, fibres and other systems, are related to the preparation of long term stable coatings. Frequently, the deposition of the catalytic layer is carried out by washcoating, requiring this step a cautious attention, especially in the case of complex geometries, like of that of foams or cloths. In the case of the deposition of layers of carbonaceous materials (CNMs), an alternative route, avoiding the washcoating, it is their direct growth by catalytic decomposition light hydrocarbons (also called CCVD), over the surface of the metallic substrate. In this case, if the metallic substrate is of stainless steel, it already contains the catalytic active phases like Fe and Ni.

In order to optimize the process of CNMs growth over structured metallic substrates, we are studying the effect of the main operational variables of the ethane decomposition reaction on stainless steel foams. In this contribution we present a study of the influence of the temperature of the activation (oxidation and reduction) stage on the type and morphology of the carbonaceous materials formed. The results obtained allow us to determine the optimal operating conditions to maximize the amount and the selectivity of the process to obtain a given type of CNM.

Septiembre, 2016 | DOI: 10.1016/j.cattod.2016.02.063

Química de Superficies y Catálisis

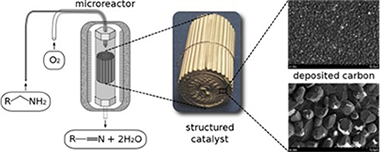

Impact of structured catalysts in amine oxidation under mild conditions

J.L. Santos; P. Navarro; J.A. Odriozola; M.A. Centeno; O.D. Pavel; B. Jurca; V.I. PàrvulescuCatalysis Today, 273 (2016) 266-272

Show abstract ▽

A structured graphene/graphite catalyst grown on a commercial austenitic stainless steel sheet providing a micromonolith was obtained by submitting the nude stainless steel structure to a carbon-rich atmosphere (first 300 mL/min of a reductive H-2/N-2 (1:1) flow, then to 180 mL/min of a CH4/H-2 (1:5)) at high temperature (900 degrees C) for 2 h. The preparation procedure resulted in a homogenous surface coated with a carbon-rich film as observed by EDX and SEM images. Further characterizations by Raman spectroscopy revealed characteristic Raman lines of graphene and crystalline graphite disposed in a hierarchical organization. The disposal of the obtained surface layers was also confirmed by grazing incidence X-ray diffraction. Besides this, XRD indicated the overlapping diffraction lines of graphite, cementite and M7C3 carbides. The graphene nature of the outermost layer was also confirmed by XPS. The catalytic behavior of the structured graphene/graphite catalyst was evaluated in the selective oxidation of heptylamine. At 200 degrees C it afforded a total conversion with a combined selectivity in heptanonitrile and N-heptylidene-heptylamine of 67% (10% heptanonitrile) that corresponds indeed to a very efficient system in the absence of any metal. Kinetic experiments with the scope to calculate the activation energies were also performed.

Septiembre, 2016 | DOI: 10.1016/j.cattod.2016.05.001

Materiales de Diseño para la Energía y Medioambiente

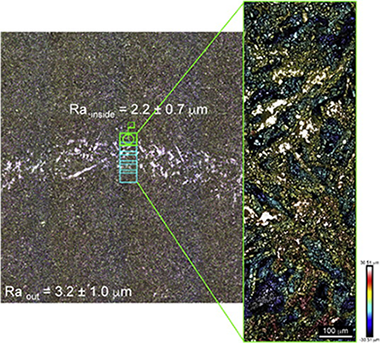

Sliding wear resistance of porous biomorphic sic ceramics

Lopez-Robledo, MJ; Gomez-Martin, A; Ramirez-Rico, J; Martinez-Fernandez, JInternational Journal of Refractory Metals & Hard Materials, 59 (2016) 26-31

Show abstract ▽

Porous biomorphic SiC ceramics were fabricated from four different wood precursors, three natural woods and one recycled wood product, by reactive infiltration of molten silicon into a carbon preform obtained from wood pyrolysis. Sliding wear resistance when sliding against a Si3N4 ball in air was studied. Tribological experiments were done with a pin-on-disk apparatus, under normal loads of 1 and 2 N, at a sliding velocity of 100 mm/s. The wear properties and the volume fraction of porosity were correlated. A commercial sintered SiC ceramic was also tested for comparison. The measured values of friction coefficient were in the range reported in literature for monolithic SiC ceramics under similar dry contact conditions. Two concurrent wear mechanisms are taking place: abrasion from the SiC debris and soft ploughing. The presence of an oxide tribolayer was assessed using energy dispersive X-ray analysis. Wear rates were found to scale with the composite porosity.

Septiembre, 2016 | DOI: 10.1016/j.ijrmhm.2016.05.004

- ‹ anterior

- 213 of 420

- siguiente ›