Artículos SCI

2021

2021

Reactividad de Sólidos

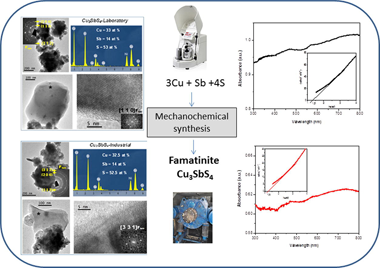

Mechanochemically synthesized ternary chalcogenide Cu3SbS4 powders in a laboratory and an industrial mill

Dutkova, E; Sayagues, MJ; Fabian, M; Balaz, M; Achimovicova, MMaterials Letters, 291 (2021) 129566

Show abstract ▽

In this work, we demonstrate the use of elemental precursors (Cu, Sb, S) to synthesize famatinite Cu3SbS4 using a laboratory planetary ball milling and an industrial eccentric vibratory milling. Cu3SbS4 was prepared for 120 min and 180 min in laboratory and industrial mill, respectively, with the utilization of protective atmosphere. The Cu3SbS4 prepared in the laboratory and industrial mill with crystallite size 14 nm and 10 nm, respectively, was confirmed by both LeBail refinement of the X-ray powder diffraction data and transmission electron microscopy. The determined band gap energy 1.31 eV and 1.24 eV is blue-shifted relative to the bulk Cu3SbS4. The synthesis of Cu3SbS4 by a scalable milling process represents a prospective route for mass production of material with potential photovoltaic properties. In this work, we demonstrate the use of elemental precursors (Cu, Sb, S) to synthesize famatinite Cu3SbS4 using a laboratory planetary ball milling and an industrial eccentric vibratory milling. Cu3SbS4 was prepared for 120 min and 180 min in laboratory and industrial mill, respectively, with the utilization of protective atmosphere. The Cu3SbS4 prepared in the laboratory and industrial mill with crystallite size 14 nm and 10 nm, respectively, was confirmed by both LeBail refinement of the X-ray powder diffraction data and transmission electron microscopy. The determined band gap energy 1.31 eV and 1.24 eV is blue-shifted relative to the bulk Cu3SbS4. The synthesis of Cu3SbS4 by a scalable milling process represents a prospective route for mass production of material with potential photovoltaic properties.

Mayo, 2021 | DOI: 10.1016/j.matlet.2021.129566

Materiales Ópticos Multifuncionales

Toward Commercialization of Stable Devices: An Overview on Encapsulation of Hybrid Organic-Inorganic Perovskite Solar Cells

Aranda, Clara A.; Calio, Laura; Salado, ManuelCrystals, 11 (2021) 519

Show abstract ▽

Perovskite solar cells (PSCs) represent a promising technology for energy harvesting due to high power conversion efficiencies up to 26%, easy manufacturing, and convenient deposition techniques, leading to added advantages over other contemporary competitors. In order to promote this technology toward commercialization though, stability issues need to be addressed. Lately, many researchers have explored several techniques to improve the stability of the environmentally-sensitive perovskite solar devices. Challenges posed by environmental factors like moisture, oxygen, temperature, and UV-light exposure, could be overcome by device encapsulation. This review focuses the attention on the different materials, methods, and requirements for suitable encapsulated perovskite solar cells. A depth analysis on the current stability tests is also included, since accurate and reliable testing conditions are needed in order to reduce mismatching involved in reporting the efficiencies of PSC.

Mayo, 2021 | DOI: 10.3390/cryst11050519

Materiales de Diseño para la Energía y Medioambiente

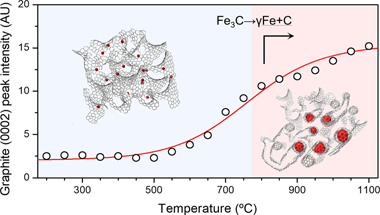

Structural Evolution in Iron-Catalyzed Graphitization of Hard Carbons

Gomez-Martin, A; Schnepp, Z; Ramirez-Rico, JChemistry of Materials, 33 (2021) 3087-3097

Show abstract ▽

Despite the recent interest in catalytic graphitization to obtain graphite-like materials from hard-carbon sources, many aspects of its mechanism are still poorly unknown. We performed a series of in situ experiments to study phase transformations during graphitization of a hard-carbon precursor using an iron catalyst at temperatures up to 1100 degrees C and ex situ total scattering experiments up to 2000 degrees C to study the structural evolution of the resulting graphitized carbon. Our results show that upon heating and cooling, iron undergoes a series of reductions to form hematite, magnetite, and wustite before forming a carbide that later decomposes into metallic iron and additional graphite and that the graphitization fraction increases with increasing peak temperature. Structural development with temperature results in decreasing sheet curvature and increased stacking, along with a decrease in turbostratic disorder up to 1600 degrees C. Higher graphitization temperatures result in larger graphitic domains without further ordering of the graphene sheets. Our results have implications for the synthesis of novel biomass-derived carbon materials with enhanced crystallinity.

Mayo, 2021 | DOI: 10.1021/acs.chemmater.0c04385

Materiales Avanzados

Synthesis of clay geopolymers using olive pomace fly ash as an alternative activator. Influence of the additional commercial alkaline activator used

Gomez-Casero, MA; Moral-Moral, FJ; Perez-Villarejo, L; Sanchez-Soto, PJ; Eliche-Quesada, DJournal of Materials Research and Technology-JMR&T 12 (2021) 1762-1776

Show abstract ▽

In this research, the use of olive pomace fly ash (OPFA) as an alkaline source for the activation of calcined clays (CC) from Bailen (Jaen, Spain) was studied. The optimal composition was obtained for 70 wt % CC and 30 wt % OPFA. The physical, mechanical and thermal properties of control geopolymers that use water as a liquid medium have been studied and compared with geopolymers that use additional activating solutions as sodium or potassium hydroxide solutions (8 M), or a mixture of alkaline hydroxide and alkaline silicate solution (NaOH-Na2SiO3 or KOH-K2SiO3). The results showed that OPFA can be used as an alkaline activator, showing mechanical properties slightly lower than those obtained when additional alkaline hydroxide activating solutions were used. The best compressive strength was obtained for geopolymers that use alkaline silicates as an activating solution. However, the best thermal insulation properties were obtained for control geopolymers. The microstructural characteristics of the geopolymers were evaluated by means of X-ray diffraction (XRD), Fourier transform infrared (FTIR) spectroscopy and Scanning Electron Microscopy (SEM-EDS) that corroborate the formation of geopolymeric gel in all the specimens, being the amount of gel formed greater in samples using commercial potassium activating solutions. These results demonstrate the feasibility of using this type of waste, OPFA, as activating reagents in the manufacture of geopolymers or alkaline activated materials. The manufactured geopolymers can be used as compressed earth blocks for walls and partitions, since the specimens pursue mechanical properties that comply with current regulations, presenting better thermal insulation properties.

Mayo, 2021 | DOI: 10.1016/j.jmrt.2021.03.102

Química de Superficies y Catálisis

Understanding the opportunities of metal-organic frameworks (MOFs) for CO2 capture and gas-phase CO2 conversion processes: a comprehensive overview

Gandara-Loe, J; Pastor-Perez, L; Bobadilla, LF; Odriozola, JA; Reina, TRReaction Chemistry & Engineering, 6 (2021) 787-814

Show abstract ▽

The rapid increase in the concentration of atmospheric carbon dioxide is one of the most pressing problems facing our planet. This challenge has motivated the development of different strategies not only in the reduction of CO2 concentrations via green energy alternatives but also in the capture and conversion of CO2 into value-added products. Metal-organic frameworks (MOFs) are a relatively new class of porous materials with unique structural characteristics such as high surface areas, chemical tunability and stability, and have been extensively studied as promising materials to address this challenge. This comprehensive review identifies the specific structural and chemical properties of MOFs that result in advanced CO2 capture capacities and fairly encouraging catalytic CO2 conversion behaviour. More importantly, we describe an interconnection among the unique properties of MOFs and the engineering aspects of these intriguing materials towards CO2 capture and conversion processes.

Mayo, 2021 | DOI: 10.1039/d1re00034a

- ‹ anterior

- 86 of 420

- siguiente ›