Artículos SCI

2015

2015

Materiales Avanzados

Valorization and inertization of galvanic sludge waste in clay bricks

Perez-Villarejo, L; Martinez-Martinez, S; Carrasco-Hurtado, B; Eliche-Quesada, D; Urena-Nieto, C; Sanchez-Soto, PJApplied Clay Science, 105-106 (2015) 89-99

Show abstract ▽

Galvanic sludge wastes (GSW) are produced by the physico-chemical treatments of wastewater generated by electroplating plants. These materials have a significant potential for the production of clay ceramic bricks. This paper focuses on the viability of the inertization of heavy metals from GSW mixed with clays. The original materials were obtained by mixing three types of raw clay (red, yellow and black) in equal parts with GSW. These mixtures were characterized by XRD, XRF, and chemical elemental analysis CHNS. The dosage of GSW in the clay–GSW bricks was up to 5 wt.%. The bricks were then manufactured using conventional processes. The influence of the amount of GSW was evaluated after firing the clay–GSW composites at 950 °C for 1 h. The engineering properties of the fired samples, such as density, water absorption, open porosity, water suction and compressive strength, with and without the GSW, were determined. The incorporation of GSW into the clay mix clearly decreased the linear shrinkage and bulk density of the bricks in comparison with the fired clay used as a control. These GSW–clay composites also showed lower open porosity. According to the results obtained for the bulk density of the bricks, samples with GSW addition showed slightly lower values of open porosity than clay bodies, indicating that the GSW–clay samples had slightly higher closed porosity values. This was also shown by SEM. The open porosity, SEM and pore size distribution tests indicated that the porosity generated by the addition of GSW was mainly closed and, therefore, GSW bricks had excellent mechanical properties. The environmental risks of the incorporation of GSW, rich in heavy metals (Cr, Zn, Ni and others), to a clay matrix were evaluated by leaching tests of the fired products. The results indicated a successful inertization of the pollutants.

Marzo, 2015 | DOI: 10.1016/j.clay.2014.12.022

Materiales Ópticos Multifuncionales

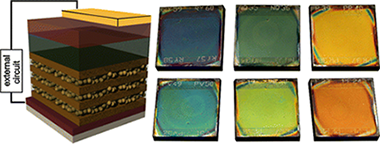

Highly Efficient Perovskite Solar Cells with Tunable Structural Color

W. Zhang, M. Anaya, G. Lozano, M.E. Calvo, M.B. Johnston, H. Míguez, H.J. SnaithNano Letters, 15 (2015) 1698-1702

Show abstract ▽

The performance of perovskite solar cells has been progressing over the past few years and efficiency is likely to continue to increase. However, a negative aspect for the integration of perovskite solar cells in the built environment is that the color gamut available in these materials is very limited and does not cover the green-to-blue region of the visible spectrum, which has been a big selling point for organic photovoltaics. Here, we integrate a porous photonic crystal (PC) scaffold within the photoactive layer of an opaque perovskite solar cell following a bottom-up approach employing inexpensive and scalable liquid processing techniques. The photovoltaic devices presented herein show high efficiency with tunable color across the visible spectrum. This now imbues the perovskite solar cells with highly desirable properties for cladding in the built environment and encourages design of sustainable colorful buildings and iridescent electric vehicles as future power generation sources.

Marzo, 2015 | DOI: 10.1021/nl504349z

Reactividad de Sólidos

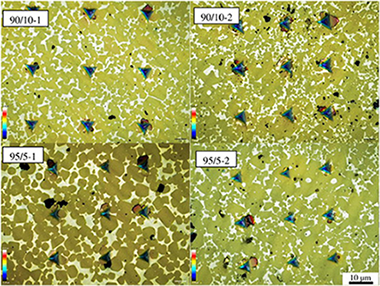

Nanoindentation of (Ti,Ta)(C,N)-Co cermets prepared by methods of mechanochemistry

Hvizdos, Pavol; Balko, Jan; Manuel Cordoba, Jose; Chicardi, ErnestoInternational Journal of Refractory Metals & Hard Materials, 49 (2015) 219-224

Show abstract ▽

Four materials TixTa(1 - x)C(0.5)N(0.5)-20%Co of two chemical compositions (x = 0.9 and 0.95) and two high energy milling methods (one stage and two stage milling) have been prepared. Nano-hardness and elastic modulus for microstructure as a whole and for individual constituent phases (matrix and carbide grains) were obtained by instrumented indentation. Individual targeted indentations as well as grid nanoindentation technique were used to discern the individual constituents' properties. Maximum loads of 20 mN for individual phases and 300 mN for composite microstructure were applied. Materials with higher amount of Ti had larger grains but the milling procedure had stronger influence on the grain size. The two step milling resulted in finer microstructures but with a much wider grain size distribution. Final composite mechanical properties, however, were very similar. Hardness and indentation elasticity modulus of all materials were comparable within the errors of measurement.

Marzo, 2015 | DOI: 10.1016/j.ijrmhm.2014.07.038

Materiales Ópticos Multifuncionales

Sunlight Absorption Engineering for Thermophotovoltaics: Contributions from the Optical Design

Miguez, HChemSusChem, 8 (2015) 786-788

Show abstract ▽

Nowadays, solar thermophotovoltaic systems constitute a platform in which sophisticated optical material designs are put into practice with the aim of achieving the long sought after dream of developing an efficient energy conversion device based on this concept. Recent advances demonstrate that higher efficiencies are at reach using photonic nanostructures amenable to mass production and scale-up.

Marzo, 2015 | DOI: 10.1002/cssc.201403361

Materiales de Diseño para la Energía y Medioambiente

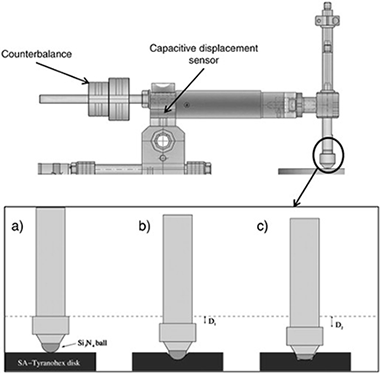

Sliding wear resistance of sintered SiC-fiber bonded ceramics

Vera, MC; Ramirez-Rico, J; Martinez-Fernandez, J; Singh, MInternational Journal of Refractory Metals & Hard Materials, 49 (2015) 232-239

Show abstract ▽

Advanced SiC-based ceramics and fiber reinforced composites are interesting materials for a wide variety of applications involving sliding wear conditions because of their excellent thermomechanical properties. The microstructure and wear resistance of sintered SiC fiber bonded ceramics (SA Tyrannohex) were studied. The material is composed of SiC-fibers in two orientations, with polygonal cross sections and cores having higher carbon content than their surroundings, as observed with SEM. A thin layer of C exists between the fibers. This layer has been found to be a turbostratic-layered structure oriented parallel to the fiber surface. XRD shows that the material is highly crystalline and composed mostly of β-SiC. Unlubricated wear behavior of the SA-Tyrannohex material when sliding against a Si3N4 ball in air at room temperature was evaluated. Experiments were performed using a pin on disk apparatus, under different normal loads of 2, 5 and 10 N at sliding speeds of 25, 50, 100 mm/s. A decrease of the friction coefficient with load was found due to the presence of the turbostratic carbon layer between the fibers. Wear rates of the order of 100 mm3/MJ were obtained, independently of sliding speed. Microfracture of the fibers is the main wear mechanism.

Marzo, 2015 | DOI: 10.1016/j.ijrmhm.2014.06.020

- ‹ anterior

- 255 of 420

- siguiente ›