Artículos SCI

2015

2015

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Photocatalytic activity of bismuth vanadates under UV-A and visible light irradiation: Inactivation of Escherichia coli vs oxidation of methanol

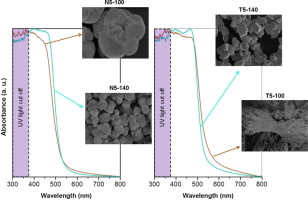

Adan, C; Marugan, J; Obregon, S; Colon, GCatalysis Today, 240 (2015) 93-99

Show abstract ▽

Four bismuth vanadates have been synthesized by using two different precipitating agents (NH3 and triethylamine) following a hydrothermal treatment at 100 °C for 2 h and at 140 °C for 20 h. Then, solids were characterized by X-ray diffraction, BET surface area, UV–vis spectroscopy and scanning microscopy techniques. The characterization of the synthesized materials showed a well crystallized scheelite monoclinic structure with different morphologies. All materials display optimum light absorption properties for visible light photocatalytic applications. The photocatalytic activity of the catalysts was investigated for the inactivation of Escherichia coli bacteria and the oxidation of methanol under UV–vis and visible light irradiation sources. Main results demonstrate that BiVO4 are photocatalytically active in the oxidation of methanol and are able to inactivate bacteria below the detection level. The activity of the catalyst decreases when using visible light, especially for methanol oxidation, pointing out differences in the reaction mechanism. In contrast with bacteria, whose interaction with the catalyst is limited to the external surface, methanol molecules can access the whole material surface.

Febrero, 2015 | DOI: 10.1016/j.cattod.2014.03.059

Nanotecnología en Superficies y Plasma

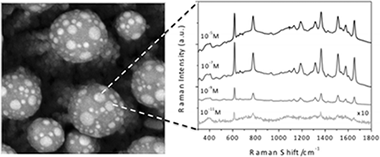

Laser Treatment of Ag@ZnO Nanorods as Long-Life-Span SERS Surfaces

Macias-Montero, M; Pelaez, RJ; Rico, VJ; Saghi, Z; Midgley, P; Afonso, CN; Gonzalez-Elipe, AR; Borras, AACS Applied Materials & Interfaces, 7 (2015) 2331-2339

Show abstract ▽

UV nanosecond laser pulses have been used to produce a unique surface nanostructuration of Ag@ZnO supported nanorods (NRs). The NRs were fabricated by plasma enhanced chemical vapor deposition (PECVD) at low temperature applying a silver layer as promoter. The irradiation of these structures with single nanosecond pulses of an ArF laser produces the melting and reshaping of the end of the NRs that aggregate in the form of bundles terminated by melted ZnO spherical particles. Well-defined silver nanoparticles (NPs), formed by phase separation at the surface of these melted ZnO particles, give rise to a broad plasmonic response consistent with their anisotropic shape. Surface enhanced Raman scattering (SERS) in the as-prepared Ag@ZnO NRs arrays was proved by using a Rhodamine 6G (Rh6G) chromophore as standard analyte. The surface modifications induced by laser treatment improve the stability of this system as SERS substrate while preserving its activity.

Febrero, 2015 | DOI: 10.1021/am506622x

Materiales Nanoestructurados y Microestructura

STEM-EELS analysis reveals stable highdensity He in nanopores of amorphous silicon coatings deposited by magnetron sputtering

Schierholz, Roland; Lacroix, Bertrand; Godinho, Vanda; Caballero-Hernandez, Jaime; Duchamp, Martial; Fernandez, AsuncionNanotechnology, 26 (2015) 075703

Show abstract ▽

A broad interest has been showed recently on the study of nanostructuring of thin films and surfaces obtained by low-energy He plasma treatments and He incorporation via magnetron sputtering. In this paper spatially resolved electron energy-loss spectroscopy in a scanning transmission electron microscope is used to locate and characterize the He state in nanoporous amorphous silicon coatings deposited by magnetron sputtering. A dedicated MATLAB program was developed to quantify the helium density inside individual pores based on the energy position shift or peak intensity of the He K-edge. A good agreement was observed between the high density (~35–60 at nm−3) and pressure (0.3–1.0 GPa) values obtained in nanoscale analysis and the values derived from macroscopic measurements (the composition obtained by proton backscattering spectroscopy coupled to the macroscopic porosity estimated from ellipsometry). This work provides new insights into these novel porous coatings, providing evidence of high-density He located inside the pores and validating the methodology applied here to characterize the formation of pores filled with the helium process gas during deposition. A similar stabilization of condensed He bubbles has been previously demonstrated by high-energy He ion implantation in metals and is newly demonstrated here using a widely employed methodology, magnetron sputtering, for achieving coatings with a high density of homogeneously distributed pores and He storage capacities as high as 21 at%.

Febrero, 2015 | DOI: 10.1088/0957-4484/26/7/075703

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

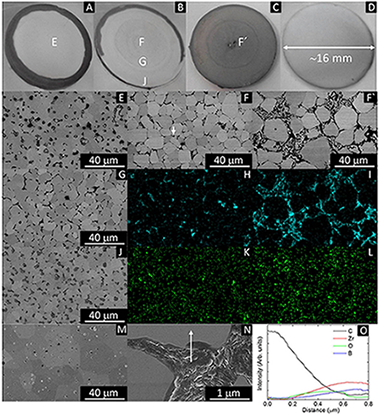

Ultra-fast and energy-efficient sintering of ceramics by electric current concentration

Zapata-Solvas, E; Gomez-Garcia, D; Dominguez-Rodriguez, A; Todd, RIScientific Reports, 5 (2015) art n. 8513

Show abstract ▽

Electric current activated/assisted sintering (ECAS) techniques, such as electrical discharge sintering (EDS) or resistive sintering (RS), have been intensively investigated for longer than 50 years. In this work, a novel system including an electrically insulated graphite die for Spark Plasma Sintering (SPS) is described, which allows the sintering of any refractory ceramic material in less than 1 minute starting from room temperature with heating rates higher than 2000°C/min and an energy consumption up to 100 times lower than with SPS. The system alternates or combines direct resistive sintering (DRS) and indirect resistive sintering (IRS). Electrical insulation of the die has been achieved through the insertion of a film made of alumina fibers between the graphite die and the graphite punches, which are protected from the alumina fiber film by a graphite foil. This system localized the electric current directly through the sample (conductive materials) as in DRS and EDS, or through the thin graphite foil (non-conductive materials) as in IRS, and is the first system capable of being used under EDS or RS conditions independently combining current concentration/localization phenomena.

Febrero, 2015 | DOI: 10.1038/srep08513

Reactividad de Sólidos

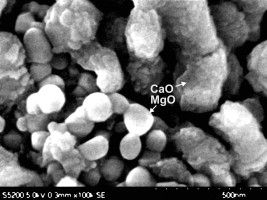

Ca-looping for postcombustion CO2 capture: A comparative analysis on the performances of dolomite and limestone

Valverde, JM; Sanchez-Jimenez, PE; Perez-Maqueda, LAApplied Energy, 138 (2015) 202-215

Show abstract ▽

The low cost and wide availability of natural limestone (CaCO3) is at the basis of the industrial competitiveness of the Ca-looping (CaL) technology for postcombustion CO2 capture as already demonstrated by similar to 1 Mw(t) scale pilot projects. A major focus of studies oriented towards further improving the efficiency of the CaL technology is how to prevent the gradual loss of capture capacity of limestone derived CaO as the number of carbonation/calcination cycles is increased. Natural dolomite (MgCa(CO3)(2)) has been proposed as an alternative sorbent precursor to limestone. Yet, carbonation of MgO is not thermodynamically favorable at CaL conditions, which may hinder the capture performance of dolomite. In the work described in this paper we carried out a thermogravimetric analysis on the multicyclic capture performance of natural dolomite under realistic regeneration conditions necessarily implying high calcination temperature, high CO2 concentration and fast transitions between the carbonation and calcination stages. Our study demonstrates that the sorbent derived from dolomite has a greater capture capacity as compared to limestone. SEM analysis shows that MgO grains in the decomposed dolomite are resistant to sintering under severe calcination conditions and segregate from CaO acting as a thermally stable support which mitigates the multicyclic loss of CaO conversion. Moreover, full decomposition of dolomite is achieved at significantly lower calcination temperatures as compared to limestone, which would help improving further the industrial competitiveness of the technology.

Febrero, 2015 | DOI: 10.1016/j.apenergy.2014.10.087

- ‹ anterior

- 257 of 420

- siguiente ›