Artículos SCI

2014

2014

Reactividad de Sólidos

Enhanced general analytical equation for the kinetics of the thermal degradation of poly(lactic acid)/montmorillonite nanocomposites driven by random scission

Carrasco, F; Perez-Maqueda, LA; Santana, OO; Maspoch, MLPolymer Degradation and Stability, 101 (2014) 52-59

Show abstract ▽

An enhanced general analytical equation has been developed in order to evaluate the kinetic parameters of the thermal degradation of nanocomposites, composed of poly(lactic acid) (PLA) and organo-modified montmorillonite (OMMT) nanoparticles. This improvement has consisted of replacing the n-order conversion function by a modified form of the Sestak–Berggren equation f(α) = c (1 − α)nαm that led to a better adjustment of experimental data and also adequately represented the conventional mechanisms for solid-state processes. The kinetic parameters so obtained have been compared to those determined by conventional differential and isoconversional methods. Given that the thermal degradation of PLA has been argued to be caused by random chain scission reactions of ester groups, the conversion function f(α) = L (L − 1)x(1 − x)L−1, corresponding to a random scission mechanism, has been tested. Once optimized the kinetic model, the thermal degradation kinetics of nanocomposites (0.5 and 2.5% of OMMT) was compared to that of the polymer matrix. Moreover, the thermal stability of nanocomposites was tested and compared to that of the polymer matrix.

Marzo, 2014 | DOI: 10.1016/j.polymdegradstab.2014.01.014

Mineralogical Characterization of the Polychrome in Cultural Heritage Artifacts (Antiquity to Date) from Southern Spain Using Micro-Raman Spectroscopy and Complementary Techniques

Perez-Rodriguez, JL; Duran, ASpectroscopy Letters: An International Journal for Rapid Communication, 47 (2014) 223-237

Show abstract ▽

This work reports on the use of micro-Raman spectroscopy for the characterization of materials used for producing the polychrome in cultural heritage artifacts from southern Spain. The micro-Raman technique was applied for the characterization of several types of artworks or for cross-sections from these works, which were produced along different historical epochs. This technique was demonstrated to be valuable for the characterization of compounds, which were all detected within the artworks studied. The identification of all of these compounds by micro-Raman was confirmed by other complementary techniques, such as micro-X-ray diffraction and scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy.

Marzo, 2014 | DOI: 10.1080/00387010.2013.791857

Reactividad de Sólidos

An investigation on the formation mechanism of nano ZrB2 powder by a magnesiothermic reaction

Jalaly, M; Bafghi, MS; Tamizifar, M; Gotor, FJJournal of Alloys and Compounds, 588 (2014) 36-41

Show abstract ▽

Nanocrystalline zirconium diboride (ZrB2) powder was produced by mechanochemistry from the magnesiothermic reduction in the Mg/ZrO2/B2O3 system. The use of high-energy milling conditions was essential to induce a mechanically induced self-sustaining reaction (MSR) and significantly reduce the milling time required for complete conversion. Under these conditions, it was found that the ignition time for ZrB2 formation was only about a few minutes. In this study, the mechanism for the formation of ZrB2 in this system was determined by studying the relevant sub-reactions, the effect of stoichiometry, and the thermal behavior of the system.

Marzo, 2014 | DOI: 10.1016/j.jallcom.2013.11.050

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

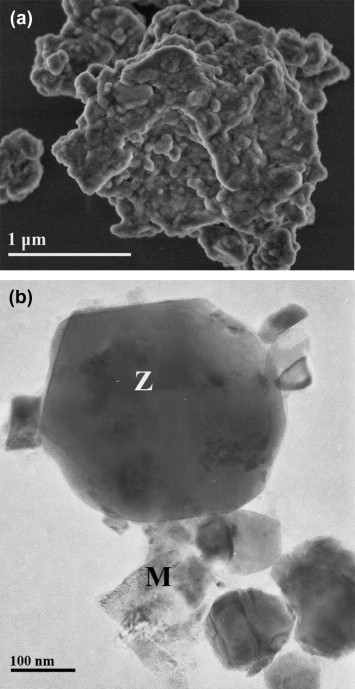

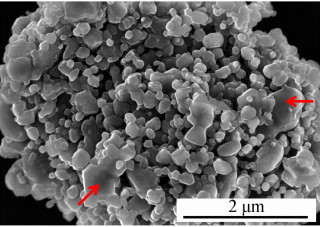

Additive-free superhard B4C with ultrafine-grained dense microstructures

Moshtaghioun, BM; Cumbrera, FL; Ortiz, AL; Castillo-Rodriguez, M; Gomez-Garcia, DJournal of the European Ceramic Society, 34 (2014) 841-848

Show abstract ▽

A unique combination of high-energy ball-milling, annealing, and spark-plasma sintering has been used to process superhard B4C ceramics with ultrafine-grained, dense microstructures from commercially available powders, without sintering additives. It was found that the ultrafine powder prepared by high-energy ball-milling is hardly at all sinterable, but that B2O3 removal by gentle annealing in Ar provides the desired sinterability. A parametric study was also conducted to elucidate the role of the temperature (1600–1800 °C), time (1–9 min), and heating ramp (100 or 200 °C/min) in the densification and grain growth, and thus to identify optimal spark-plasma sintering conditions (i.e., 1700 °C for 3 min with 100 °C/min) to densify completely (>98.5%) the B4C ceramics with retention of ultrafine grains (∼370 nm). Super-high hardness of ∼38 GPa without relevant loss of toughness (∼3 MPa m1/2) was thus achieved, attributable to the smaller grain size and to the transgranular fracture mode of the B4C ceramics.

Marzo, 2014 | DOI: 10.1016/j.jeurceramsoc.2013.10.006

Materiales de Diseño para la Energía y Medioambiente

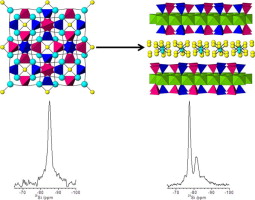

A new route of synthesis of Na-Mica-4 from sodalite

Naranjo, M; Castro, MA; Cota, A; Pavon, E; Pazos, MC; Alba, MDMicroporous and Mesoporous Materials, 188 (2014) 176-180

Show abstract ▽

Synthesis of Na-Mica-4 has been achieved by a “mix and calcine” method using sodalite and magnesium fluoride as the only precursors. Previous research found sodalite as a key intermediate reaction product in the formation of Na-Mica-4 when the NaCl melt method was employed. Similarities in structure, chemical composition and cation distribution in products using the proposed method and the NaCl melt method are described and suggest that Na-Mica-4 is a very stable product. The use of sodalite as precursor provokes microporous formation in the final mica. The absence of excess Na leads to a lower particle size and to the presence of less impurity in the calcined product. Different sodalites could be used in the synthesis of different Na-Mica-4 with presumably different physicochemical properties.

Marzo, 2014 | DOI: 10.1016/j.micromeso.2013.12.004

- ‹ anterior

- 281 of 420

- siguiente ›