Artículos SCI

2010

2010

Materiales de Diseño para la Energía y Medioambiente

Illization of kaolinite: The effect of pressure on the reaction rate

Mantovani, M; Becerro, AIClays and Clay Minerals, 58 (2010) 766-771

Show abstract ▽

Studies of the paragenesis of authigenic illite in arkosic sandstonesof various regions and ages have revealed that the illitizationof kaolinite is an important reaction accounting for the formationof authigenic illite in sandstones during burial diagenesis.The illitization of kaolinite takes place at an intermediateburial depth of 3–4 km, where pressure can reach valuesof 100 MPa ( 1000 bars). The purpose of the present study wasto analyze the effect of pressure on the rate of kaolinite illitizationin alkaline conditions. Hydrothermal reactions were conductedon KGa-1b kaolinite in KOH solution at 300°C and under pressuresof 500, 1000, and 3000 bars for 1 to 24 h. The visual examinationof the X-ray diffraction (XRD) patterns indicated a notableinfluence of pressure on the reaction rate. Molar percentagesof muscovite/illite formed at each time interval were calculatedfrom the analysis of two diagnostic XRD peaks, representingthe 060 reflections of kaolinite and muscovite/illite. The datawere modeled to obtain the initial rate of conversion at eachpressure. The results indicated that the initial rate of kaoliniteto muscovite/illite conversion is one order of magnitude greaterat 3000 bars than at 500 or 1000 bars. Comparison of these datawith those in the literature show a faster conversion rate (severalorders of magnitude) in an initially high-alkaline solutionthan in a near-neutral solution.

1000 bars). The purpose of the present study wasto analyze the effect of pressure on the rate of kaolinite illitizationin alkaline conditions. Hydrothermal reactions were conductedon KGa-1b kaolinite in KOH solution at 300°C and under pressuresof 500, 1000, and 3000 bars for 1 to 24 h. The visual examinationof the X-ray diffraction (XRD) patterns indicated a notableinfluence of pressure on the reaction rate. Molar percentagesof muscovite/illite formed at each time interval were calculatedfrom the analysis of two diagnostic XRD peaks, representingthe 060 reflections of kaolinite and muscovite/illite. The datawere modeled to obtain the initial rate of conversion at eachpressure. The results indicated that the initial rate of kaoliniteto muscovite/illite conversion is one order of magnitude greaterat 3000 bars than at 500 or 1000 bars. Comparison of these datawith those in the literature show a faster conversion rate (severalorders of magnitude) in an initially high-alkaline solutionthan in a near-neutral solution.

Diciembre, 2010 | DOI: 10.1346/CCMN.2010.0580604

Materiales Nanoestructurados y Microestructura

Effect of process parameters on mechanical and tribological performance of pulsed-DC sputtered TiC/a-C:H nanocomposite films

Shaha, KP; Pei, YT; Martinez-Martinez, D; Sanchez-Lopez, JC; De Hosson, JTMSurface and Coatings Technology, 205 (2010) 2633-2642

Show abstract ▽

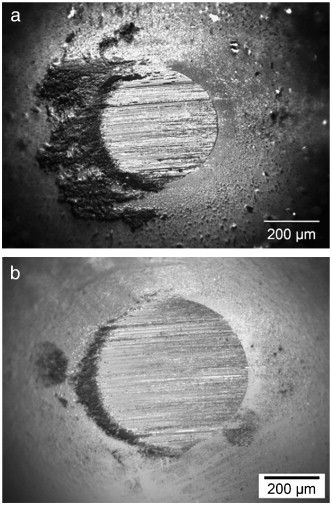

Mechanical, structural, chemical bonding (sp(3)/sp(2)). and tribological properties of films deposited by pulsed-DC sputtering of Ti targets in Ar/C2H2 plasma were studied as a function of the substrate bias voltage, Ti-target current, C2H2 flow rate and pulse frequency by nanoindentation, Raman spectroscopy and ball-on-disc tribometry. The new findings in this study comprise: dense, column-free, smooth, and ultra-low friction TiC/a-C:H films are obtained at a lower substrate bias voltage by pulsed-DC sputtering at 200 and 350 kHz frequency. The change in chemical and phase composition influences the tribological performance where the TiC/a-C:H films perform better than the pure a-C:H films. In the case of TiC/a-C:H nanocomposite films, a higher sp(2) content and the presence of TiC nanocrystallites at the sliding surface promote formation of a transfer layer and yield lower friction. In the case of a-C:H films, a higher sp(3) content and higher stress promote formation of hard wear debris during sliding, which cause abrasive wear of the ball counterpart and yield higher friction.

Diciembre, 2010 | DOI: 10.1016/j.surfcoat.2010.10.020

Nanotecnología en Superficies y Plasma

Tunable Nanostructure and Photoluminescence of Columnar ZnO Films Grown by Plasma Deposition

Romero-Gomez, P; Toudert, J; Sanchez-Valencia, JR; Borras, A; Barranco, A; Gonzalez-Elipe, ARJournal of Physical Chemistry C, 114 (2010) 20932-20940

Show abstract ▽

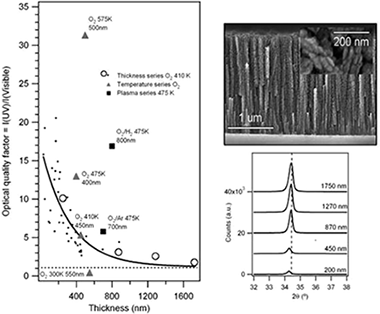

Nanoporous ZnO thin films presenting a tunable nanostructure and photoluminescence (PL) were grown by plasma enhanced vapor deposition on surface oxidized Si substrates. These films consist of c-axis oriented wurtzite ZnO nanocolumns whose topology, crystallinity, and PL can be tuned through the substrate temperature (varied in the 300-573 K range) and the nature of the plasma assistance (pure O-2, O-2/Ar, O-2/H-2, or O-2/N-2 mixture). In particular, these processing parameters influence the intensity of the UV and visible PL bands of the films, related to excitonic and defective radiative transitions, respectively. Increasing the substrate temperature enhances the UV PL and rubs out the visible PL due to the increase of grain size and the removal of interstitial defects. Additional tuning of the intensity ratio between the UV and visible bands can be done by controlling the film thickness. A decrease of the UV PL is observed when the films go thicker, an effect that is likely to be linked to the microstructure of the films rather than to their crystallinity that is improved upon increasing of the film thickness, as seen from PL spectroscopy and XRD measurements. Indeed, a gradient of stress, decreasing from the substrate to the surface, is evidenced and related to a concentration gradient of interstitial defects. The drawbacks of the thickness effect, which prohibits growing thick films with a high optical quality, can be bypassed by growing the films in a O-2/H-2 plasma.

Diciembre, 2010 | DOI: 10.1021/jp103902u

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Study of nanoporous catalysts in the selective catalytic reduction of NOx

Rico, MJO; Moreno-Tost, R; Jimenez-Lopez, A; Rodriguez-Castellon, E; Pereniguez, R; Caballero, A; Holgado, JPCatalysis Today, 158 (2010) 78-88

Show abstract ▽

Two SBA-15 type materials were synthesized using a low-cost route, a pure silica SBA-15 and an Al containing SBA-15 (with a Si/Al ratio of 10), where Al was added by a post-synthesis modification. The later solid was achieved without any significant loss in the textural properties of SBA-15, besides improving its properties as support of catalysts. Copper impregnated catalysts were prepared through the incipient wetness impregnation of the two supports. With both supports, the copper weight loading were 1, 3 and 6 wt%. The copper incorporation kept the support mesoporous structures, obtaining a better dispersion of the active phase in the containing aluminium support. All the catalysts showed a moderated catalytic activity in the SCR of NO with propane in presence of an excess of oxygen in the whole studied interval of temperatures and a much better performance was observed when using NH3 instead of propane. The changes of the active phases were studied by operando XAS spectroscopy. Factor analysis of in operando XANES results with sample SiAl_6 indicate that no Cu-0 was detected, but only Cu1+ and Cu2+. The temperature where the Cu1+/Cu2+ ratio is maximum occurs at the reaction temperature where the observed catalytic NO conversion is also maximum.

Diciembre, 2010 | DOI: 10.1016/j.cattod.2010.04.016

Química de Superficies y Catálisis

Iron-modified ceria and Au/ceria catalysts for Total and Preferential Oxidation of CO (TOX and PROX)

Laguna, OH; Centeno, MA; Arzamendi, G; Gandia, LM; Romero-Sarria, F; Odriozola, JACatalysis Today, 157 (2010) 155-159

Show abstract ▽

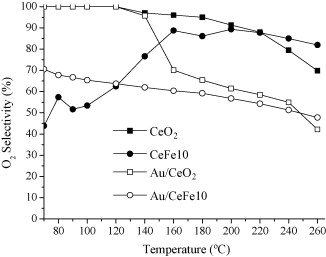

Iron-modified ceria supports containing different molar percentages of Fe (0% 10% 25% and 50%) were synthesized by thermal decomposition of the metal propionates The formation of a Ce-Fe oxide solid solution is evidenced through XRF XRD BET and Raman spectroscopy For Iron contents above 25% the formation of alpha-Fe2O3 was detected pointing out the formation of the isolated oxides The catalytic activity of the Fe-modified catalysts in the Total Oxidation of CO reaction (TOX) is higher than for the bare CeO2 material The synergy between Ce and Fe shows a maximum for 10% Fe content (CeFe10) catalyst that shows the highest CO conversion per atom of Fe incorporated Gold catalyst was also prepared on CeFe10 and its catalytic activity compared with Au/CeO2 catalyst The addition of iron to the gold catalyst resulted in an enhancement of the catalytic activity for CO oxidation especially at low temperature This Au/CeFe10 catalyst was also active and selective with excellent stability in the Preferential Oxidation of CO (PROX) showing a higher CO conversion than the Au/CeO2 catalyst at temperatures below 150 C being hardly affected by the presence of CO2 and H2O in the gas stream.

Noviembre, 2010 | DOI: 10.1016/j.cattod.2010.04.011

- ‹ anterior

- 366 of 422

- siguiente ›